Method for producing dual damascene structure

A dielectric layer and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that the side of the interconnection groove is vertical, and the double damascene cannot meet the formation of round corners of the through hole at the same time, so as to avoid Effect of damage and short etching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

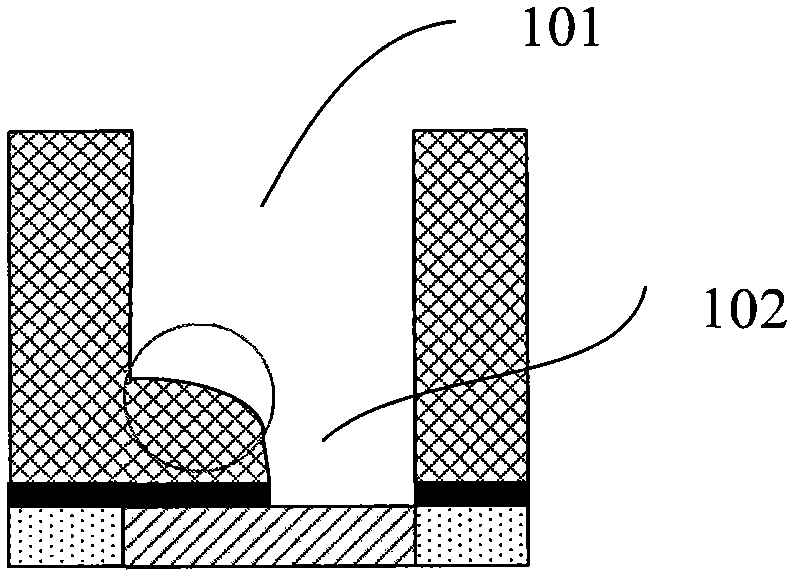

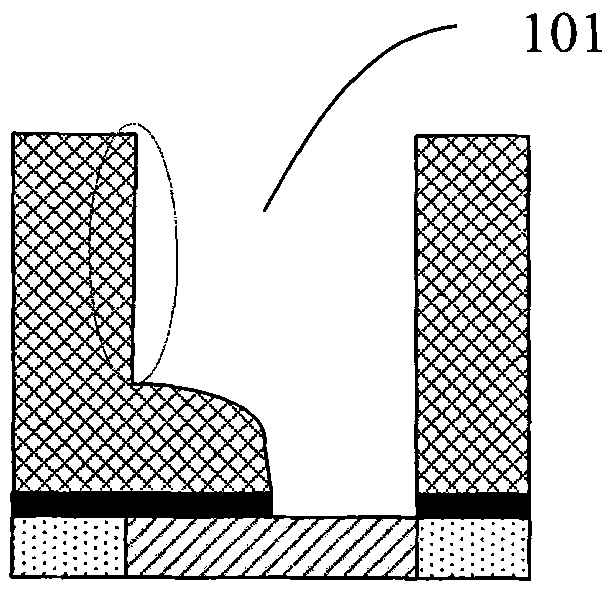

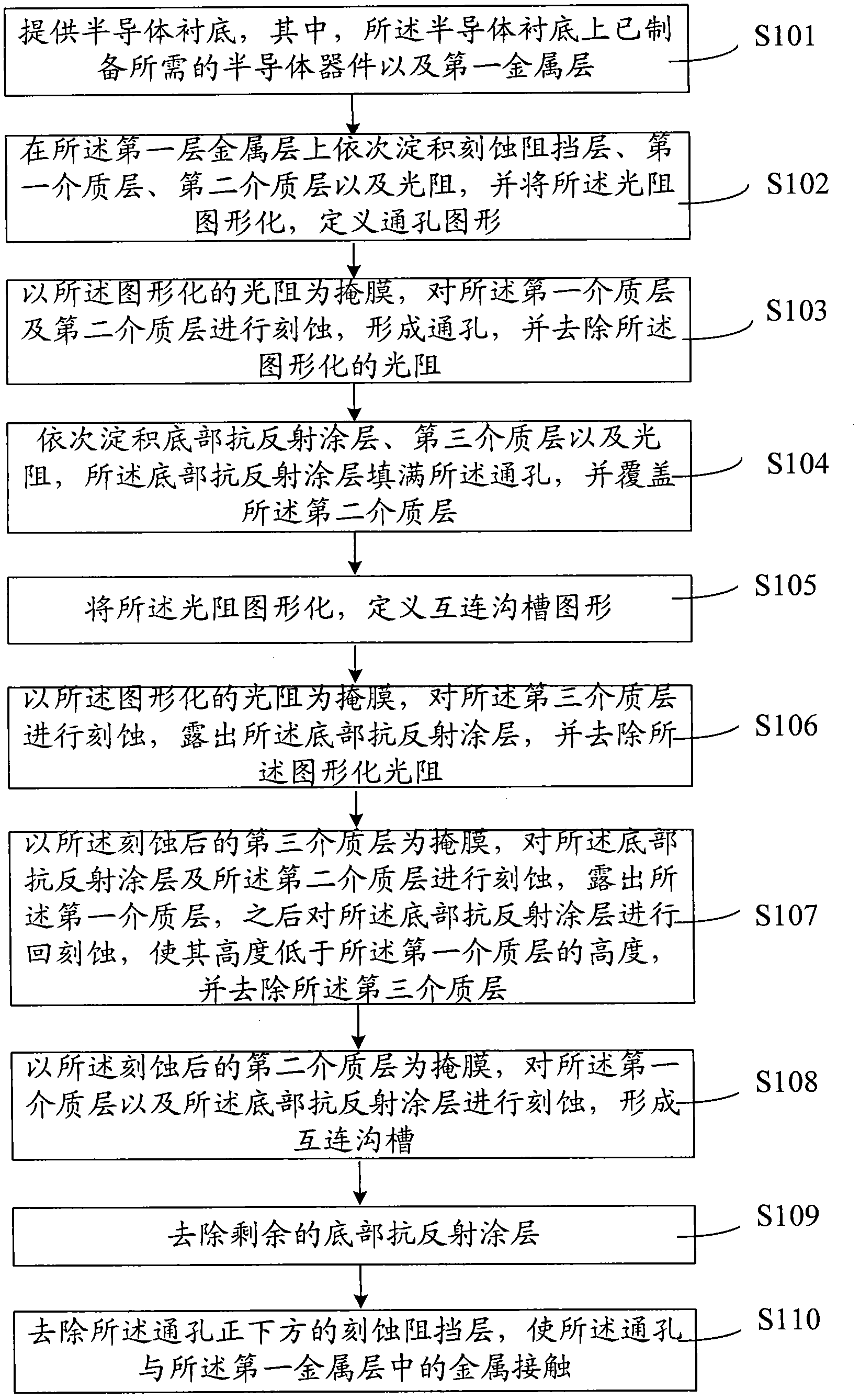

[0070] The method for preparing the double damascene structure proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use imprecise ratios, which are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

[0071] The core idea of the present invention is to provide a method for preparing a double damascene structure. The method first deposits a part of the silicon-containing coating in the through hole, then deposits the bottom anti-reflective coating, and then performs interconnect trench etching. When the exposed When the silicon-containing coating is mentioned, the CF 4 , N 2 and Ar and continue etching, or pass through CF first 4 , N 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com