Semiconductor structure and manufacturing method of semiconductor structure

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reducing the yield of semiconductor structures, affecting the electrical performance of gate structures, and easily over-etching the side of polysilicon, etc. To achieve the effect of guaranteed electrical performance, good electrical performance and guaranteed yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It can be known from the background art that during the formation process of the gate structure of polysilicon material, due to the characteristics of polysilicon material and the limitations of the etching process, the side surface of polysilicon will be easily over-etched during the etching process, thereby affecting the gate structure. electrical properties, reducing the yield of semiconductor devices.

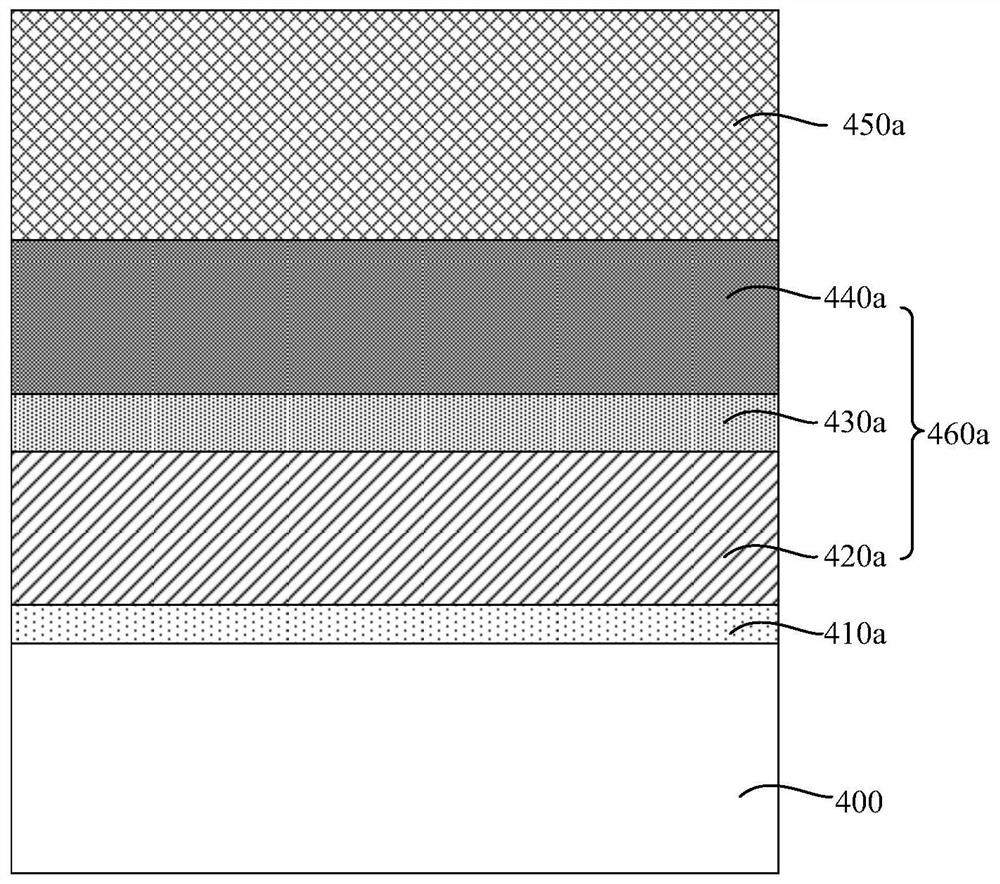

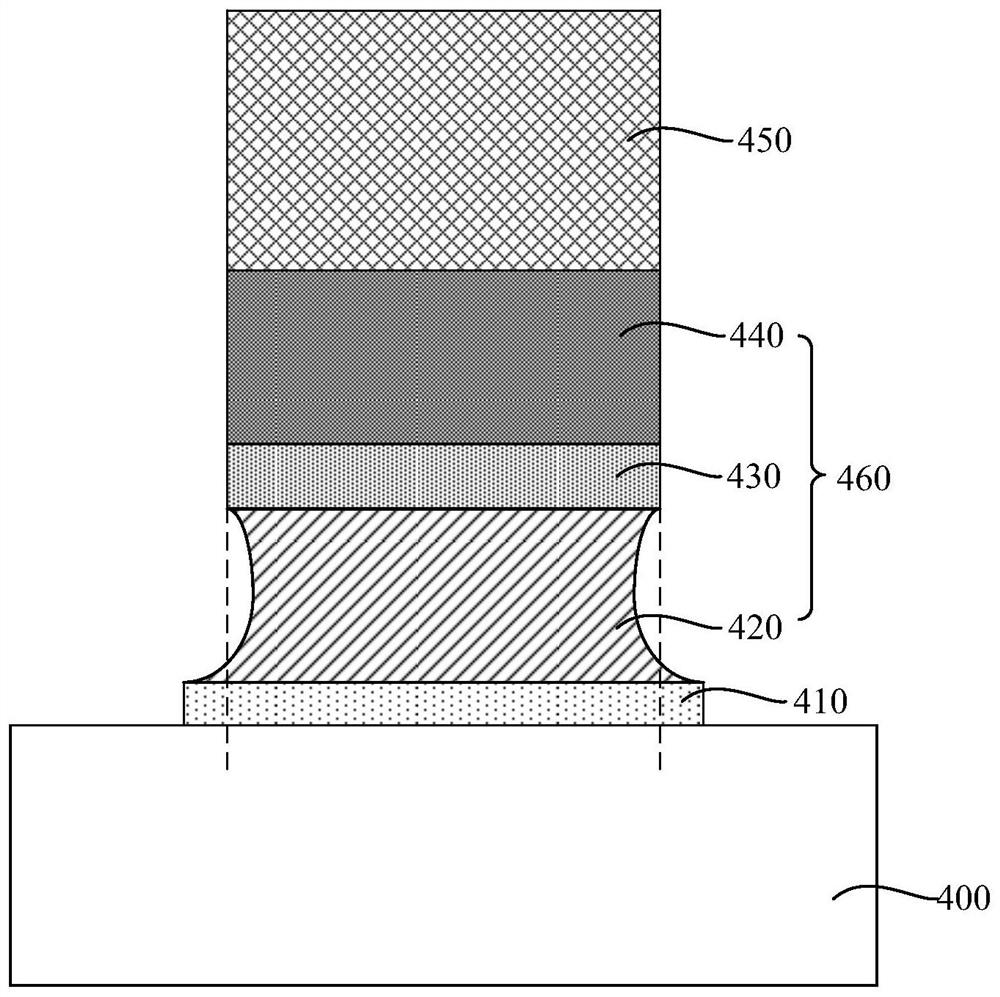

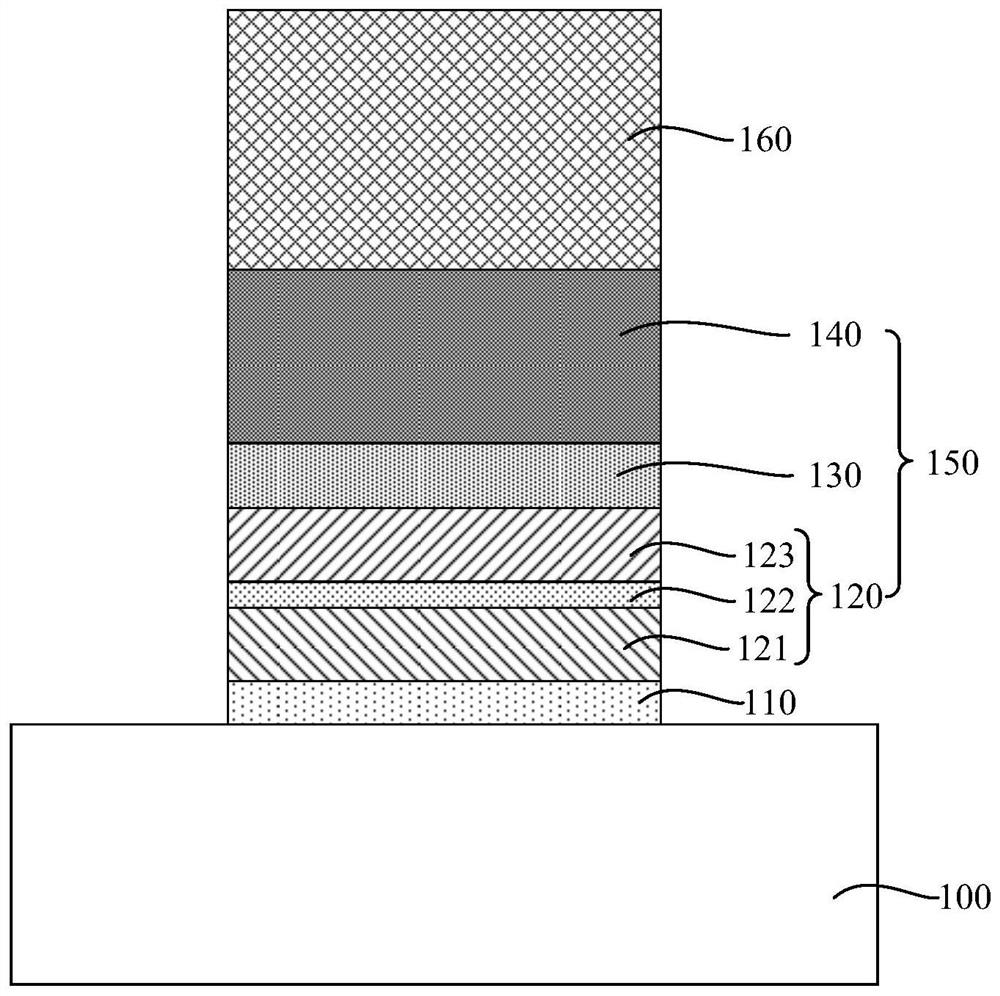

[0030] figure 1 is a schematic structural diagram of an existing semiconductor structure before etching, figure 2 for figure 1 Schematic diagram of the semiconductor structure after etching.

[0031] The steps of forming the semiconductor structure include: Reference figure 1 and figure 2 , a substrate 400 is provided, and an initial gate dielectric layer 410a, an initial first conductive layer 420a, an initial barrier layer 430a, an initial second conductive layer 440a, and an initial insulating cover layer 450a are sequentially stacked on the substrate 400. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com