A preparation method and application of silicon-based microneedles by metal-assisted wet etching

A wet etching, metal-assisted technology, applied in the direction of microneedle, metal material coating process, needle head, etc., can solve problems such as unfavorable large-scale manufacturing, cumbersome process, unfavorable commercial application, etc., and achieve good linear response, Simple process and controllable position of microneedles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method for preparing silicon-based microneedles by metal-assisted wet etching, comprising the following steps:

[0032] The surface of the pretreated silicon wafer is coated with photoresist for patterning to obtain a sample;

[0033] depositing the sample in a mixed solution of silver nitrate-hydrofluoric acid-ultrapure water to obtain a deposited silicon wafer;

[0034] The deposited silicon wafer is etched in a hydrofluoric acid-hydrogen peroxide mixed solution, washed and soaked in a piranha solution, and then silicon nanowires are removed to obtain silicon-based microneedles.

[0035] The present invention proposes a completely new process step that solves the problems of cost, instrumentation and operation. Using the principle of metal-assisted wet etching combined with semiconductor technology, the requirements for silicon-based samples are very low, and the requirements for the experimental environment are not high. The requ...

Embodiment 1

[0054] A clean and flat silicon-based substrate is selected. The present invention selects a (100) crystal-oriented silicon wafer. There is no requirement for doping. The silicon wafer needs to be soaked and cleaned with acetone for 5 minutes, and then rinsed with ultrapure water for 1 minute. Put the silicon wafer into the piranha solution (H 2 SO 4 :H 2 O 2 = 3:1 volume ratio) for 10 minutes, and it is necessary to ensure that the temperature of the piranha solution is at room temperature. This step is to form an oxide layer. The silicon wafer with the oxide layer was washed with ultrapure water for 1 min, and then immersed in a 5% hydrofluoric acid solution for 5 min to remove the oxide layer to expose a new silicon interface, rinsed with ultrapure water for 1 min and dried with nitrogen.

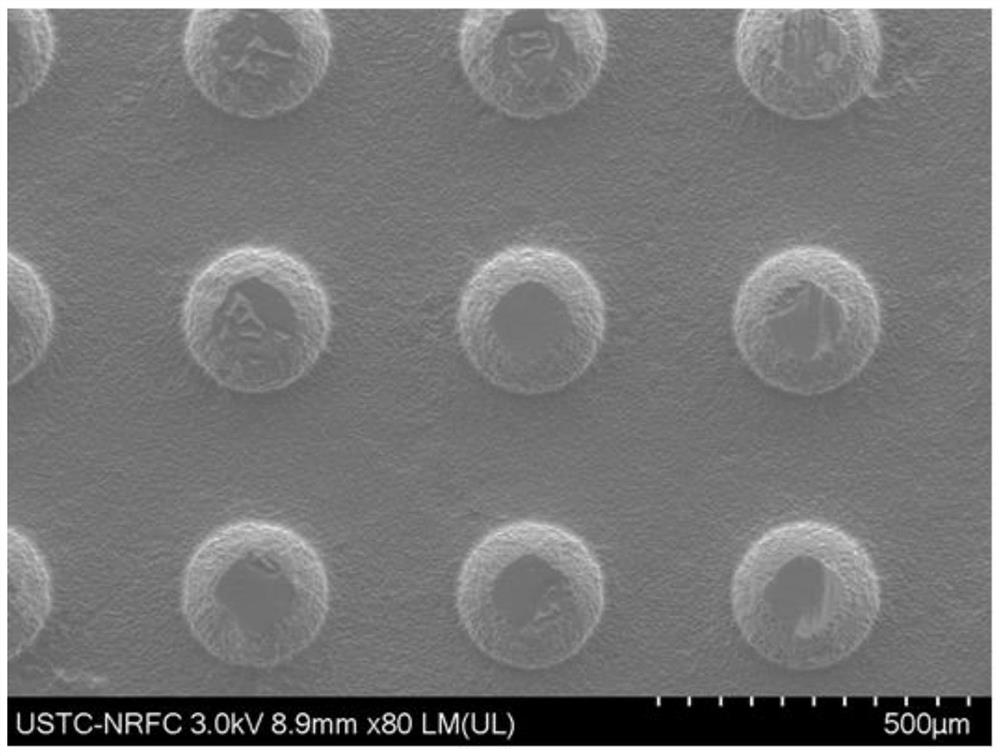

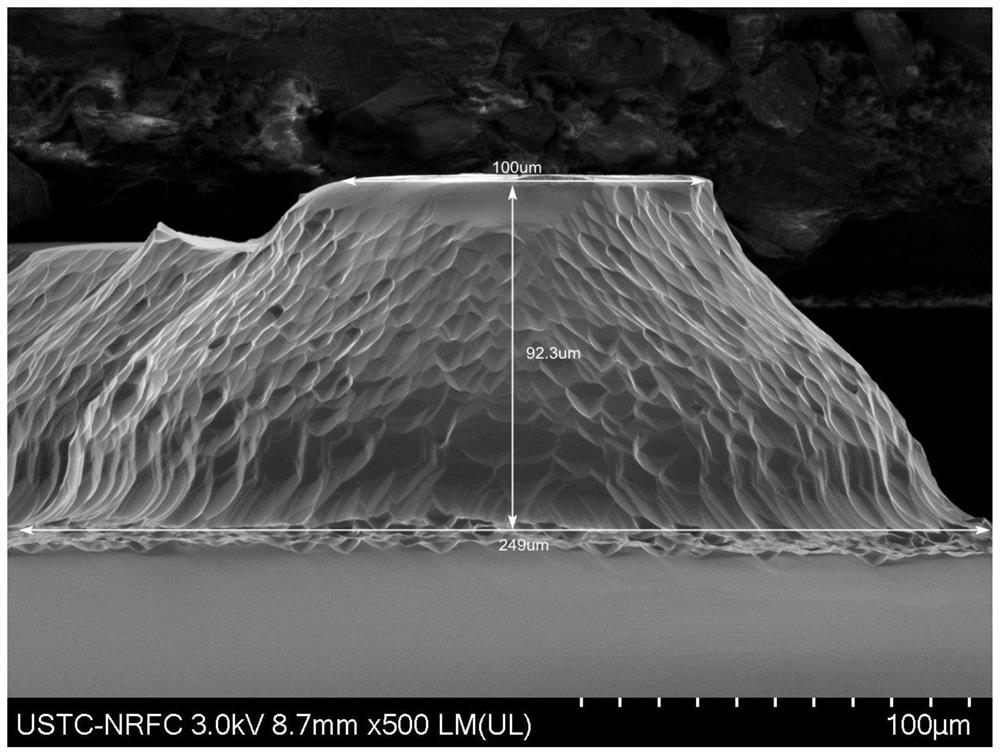

[0055] The pattern of the photolithography mask is a circle with a diameter of 250μm and an array with a spacing of 200um outside the circle. The uniform photoresist (S1813) is applie...

Embodiment 2

[0061] The difference from Example 1 is that it was placed in the etching solution to etch for 8 minutes.

[0062] The height of the silicon-based microneedles prepared in Example 2 is about 110 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com