Circuit board substrate and manufacturing method thereof

A manufacturing method and board substrate technology, which is applied in the direction of circuit substrate materials, printed circuit manufacturing, printed circuits, etc., can solve the problems of increasing the production cost of circuit boards, poor flexibility of stainless steel sheets, and high prices of stainless steel sheets, so as to prevent ion migration. , reduce production cost, increase the effect of flexural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The circuit board substrate provided by the technical solution and the manufacturing method thereof will be further described in detail below in conjunction with the embodiments.

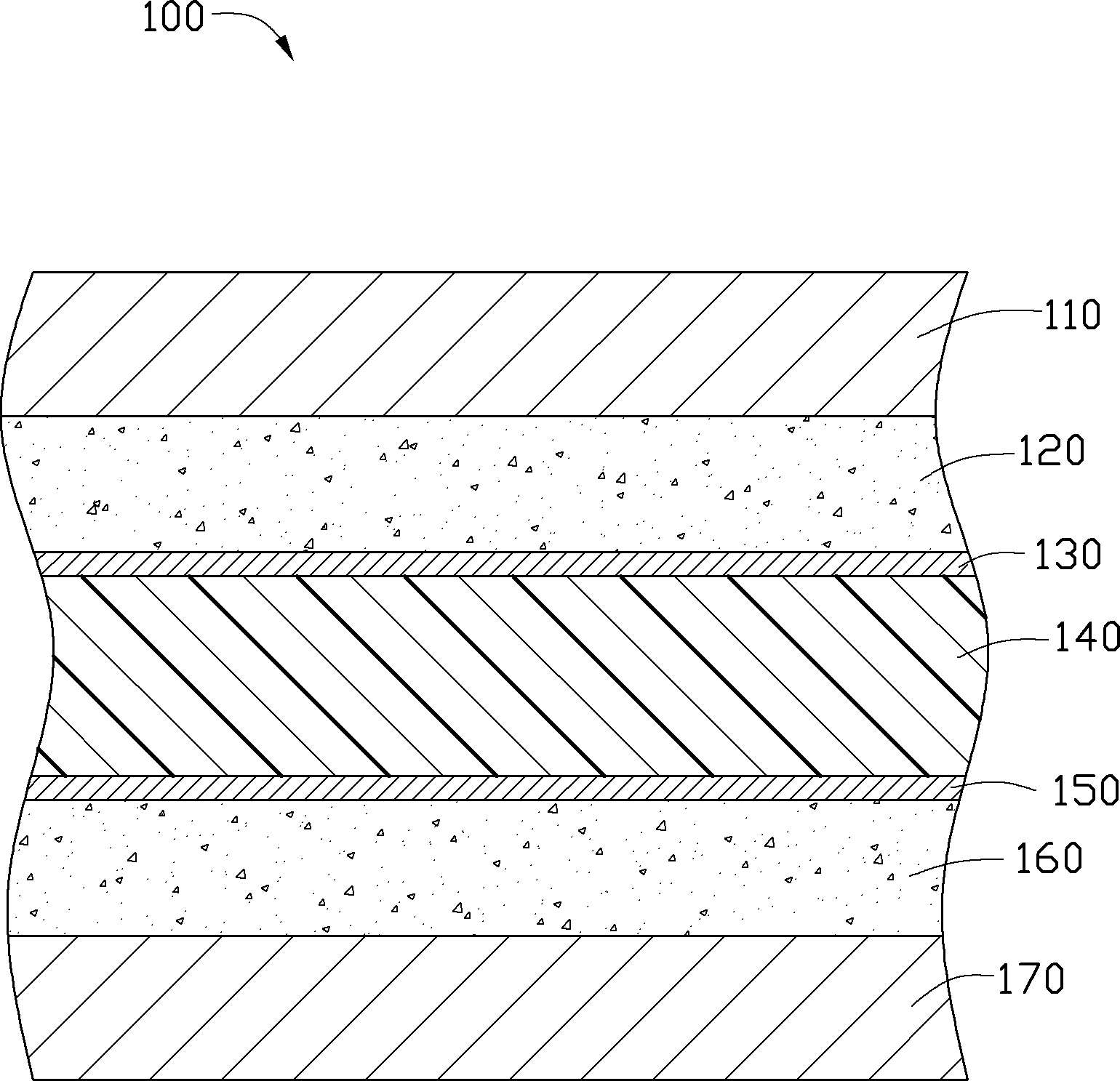

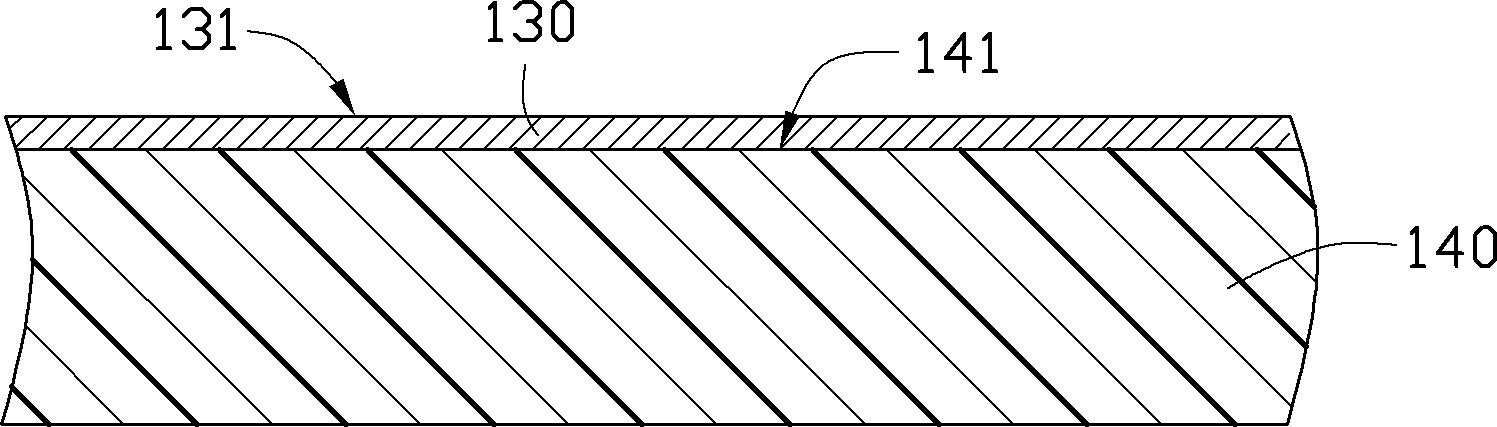

[0032] see figure 1 , this technical solution provides a circuit board substrate 100, which includes a first metal layer 110, a first adhesive layer 120, a first epoxy resin composite material layer 130, an insulating substrate layer 140, a second epoxy resin layer stacked in sequence. The composite material layer 150 , the second glue layer 160 and the second metal layer 170 .

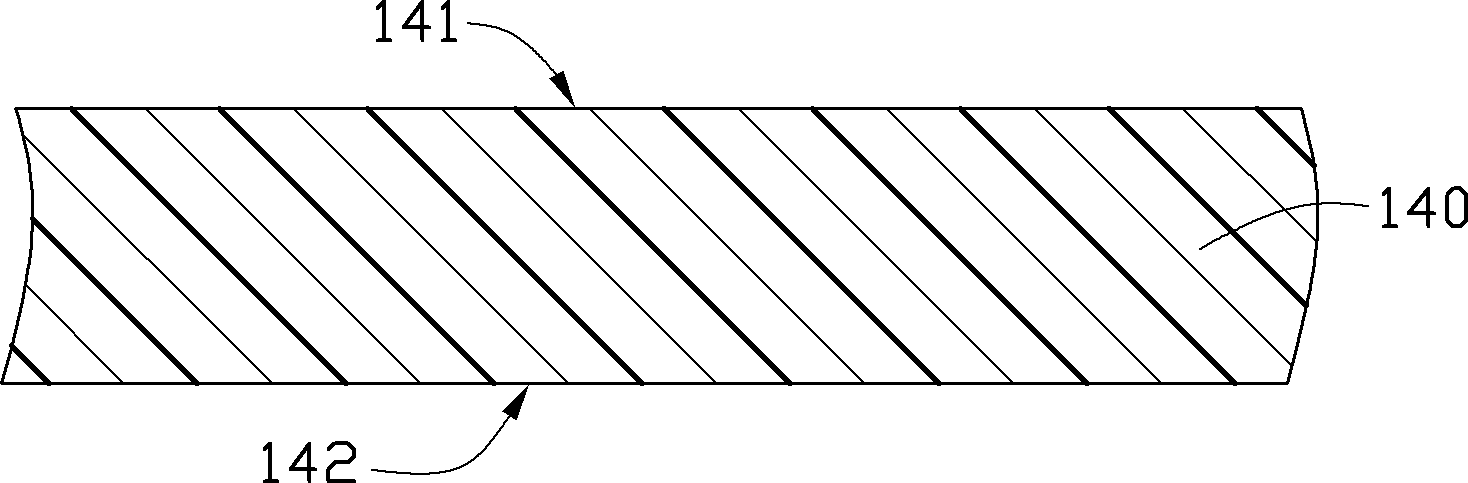

[0033] The insulating base material layer 140 is used for carrying the first epoxy resin composite material layer 130 and the second epoxy resin composite material layer 150 , and plays a role of electrical insulation. In this embodiment, the insulating base material layer 140 is made of polyimide. The thickness of the insulating substrate layer 140 can be set according to actual needs, and its thickness can be 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com