Zeolite molecular sieve catalyst and preparation method thereof

A technology of zeolite molecular sieve and catalyst, which is applied in the field of zeolite molecular sieve catalyst and its preparation, and can solve the problems of low selectivity and short service life of low-carbon olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

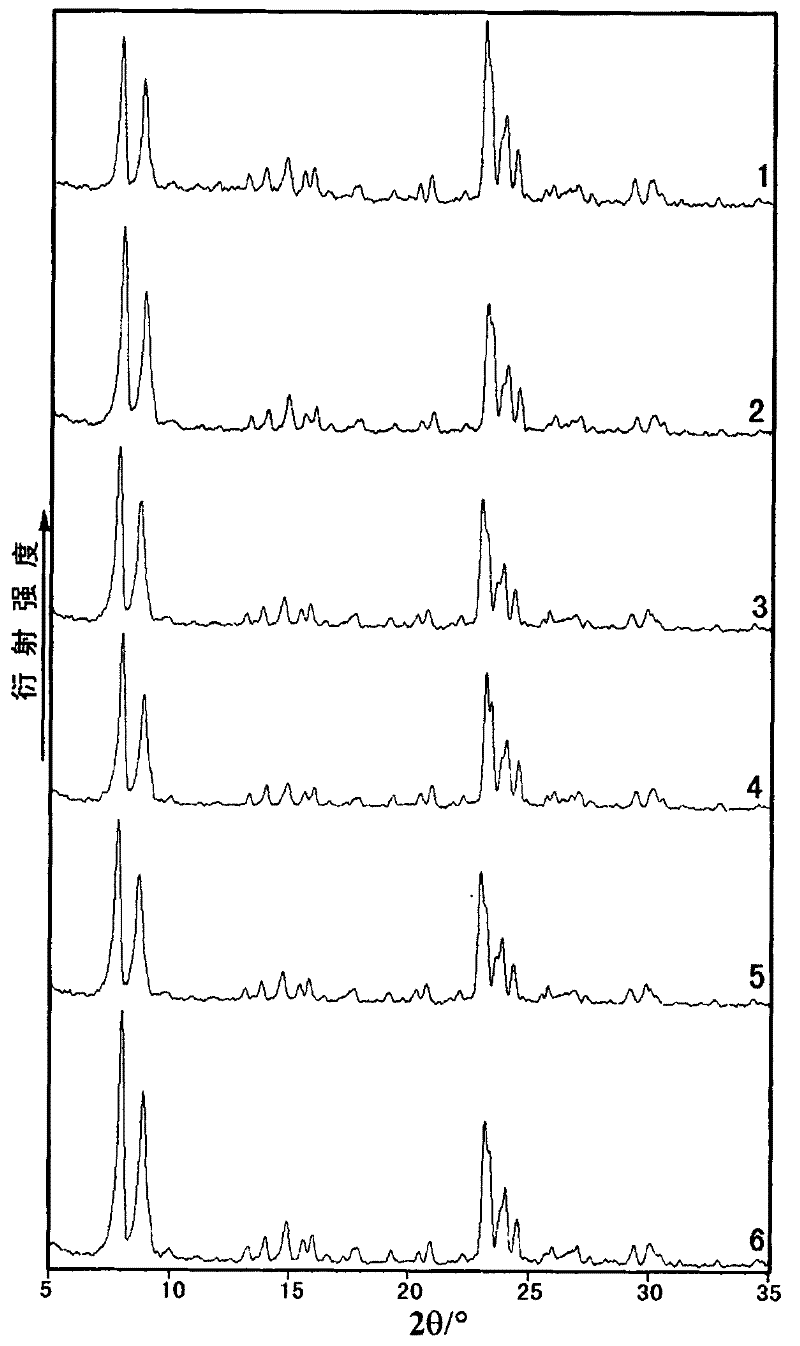

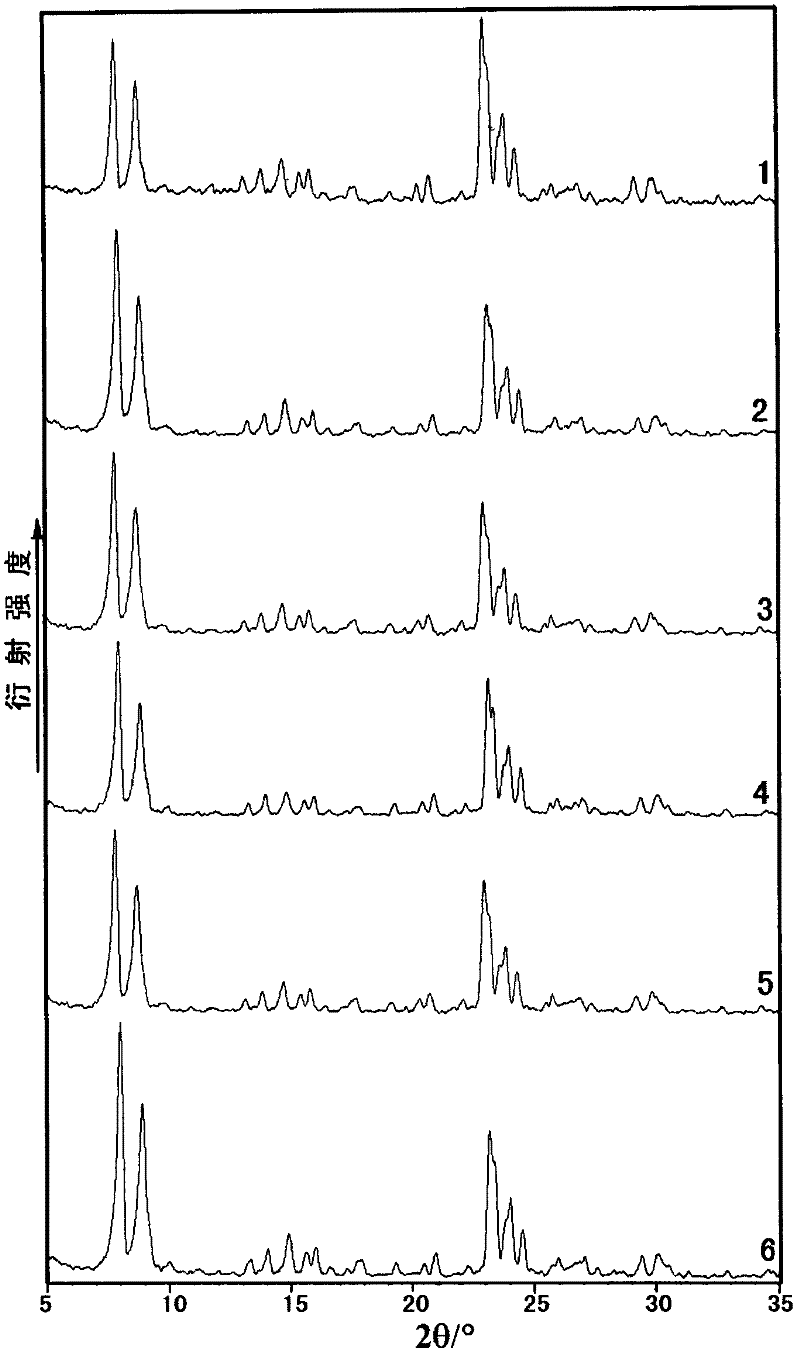

Image

Examples

Embodiment 1

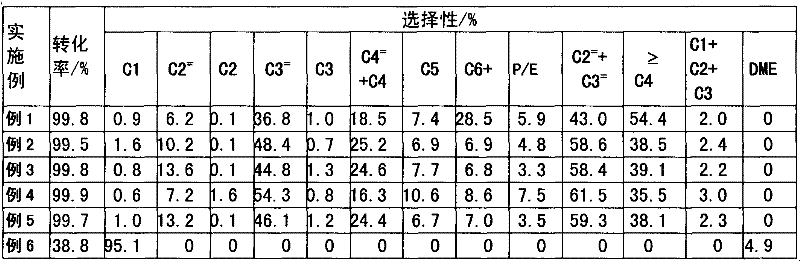

[0022] SAR=255H-ZSM-5 zeolite molecular sieve powder crystal produced by Shanghai Fuxu Molecular Sieve Co., Ltd., after being pressed into tablets, 5mL of 20-40 mesh particles were taken as a catalyst and packed in a catalytic evaluation reactor at 480 Reaction under the condition of ℃, the mass concentration of methanol is 33%, and the hourly space velocity of methanol liquid is 1h -1 . The average value of its 100-hour methanol dehydration to propylene (MTP) reaction product selectivity is shown in Example 1 in Table 1.

Embodiment 2

[0024] Take 1.92 grams of the raw material solution, dilute it to 15 grams with deionized water and mix it with 10 g of H-ZSM-5 zeolite molecular sieve powder crystals used in Example 1 to form a uniform slurry, which is reacted in a 40 mL autoclave at 180 ° C After 3 hours, the product was filtered, washed, dried, and calcined at 550°C for 6 hours to remove the organic template agent, and the composite zeolite molecular sieve powder crystal was obtained. After tablet molding, 5 mL of 20-40 mesh particles were collected as a catalyst after being crushed and screened, and packed in a catalytic evaluation reactor. The mass ratio of the H-ZSM-5 zeolite molecular sieve to the Silicalite-I zeolite molecular sieve in the catalyst is calculated to be 100:1. The average value of its 100-hour methanol dehydration to propylene (MTP) reaction product selectivity is shown in Example 2 in Table 1.

Embodiment 3

[0026] Take 0.96 g of the raw material solution, dilute it to 15 g with deionized water and mix it with 10 g of the H-ZSM-5 zeolite molecular sieve powder used in Example 1 to form a uniform slurry, which is reacted in a 40 mL autoclave at 180 ° C After 2 hours, the product was filtered, washed, dried, and calcined at 550°C for 6 hours to remove the organic template agent, and the compound zeolite molecular sieve powder crystal was obtained. After tablet molding, 5 mL of 20-40 mesh particles were collected as a catalyst after being crushed and screened, and packed in a catalytic evaluation reactor. The mass ratio of the H-ZSM-5 zeolite molecular sieve to the Silicalite-I zeolite molecular sieve in the catalyst is calculated to be 200:1. The average value of its 100-hour methanol dehydration to propylene (MTP) reaction product selectivity is shown in Example 3 in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com