Semiconductive shielding material of rubber cable and preparation method thereof

A rubber cable, semi-conductive technology, applied in the direction of insulated cables, conductive materials dispersed in non-conductive inorganic materials, cables, etc., can solve the problem that the compatibility of semi-conductive shielding layer peelable insulation rubber cannot reach higher voltages Level requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] The components and parts by mass in the formula are: 80 parts of EVM (450), 20 parts of HNBR, 3 parts of P50 anti-hydrolysis agent; 9 parts of microcrystalline wax in the plasticizer, 10 parts of dioctyl fat, zinc stearate 1 part; 3 parts of activator zinc oxide, 3 parts of anti-aging agent RD, 70 parts of conductive carbon black 420B, 5 parts of dispersing agent Molder, 3 parts of vulcanizing agent DCP, 2 parts of vulcanization aid TAIC.

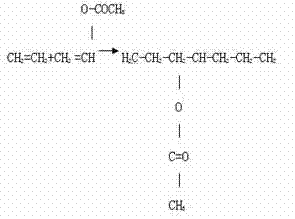

[0017] Among them, EVM450 is saturated rubber, and its molecular structure is:

[0018]

[0019] EVM450 has the following characteristics: ①Excellent heat aging resistance, the maximum service temperature is 175°C, which is much higher than the ethylene-propylene rubber used for rubber insulation in the manufacture of medium and high voltage cables. ②Excellent weather / ozone / oil resistance. ③ It can be seen from the molecular structure that the non-polar methine group makes it have good resistance to low temperature flexing and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com