Emissions treatment system with ammonia-generating and SCR catalysts

A technology of SCR catalyst and exhaust gas treatment, which is applied in the direction of gas treatment, exhaust equipment, chemical instruments and methods, etc., and can solve problems such as limiting the range of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] The oxidation catalyst was placed on a flow-through monolithic substrate having a 50in 3 capacity (0.83 L), a cell density of 300 cells per square inch, and a wall thickness of approximately 125 μm. Catalyst contains 2.5g / in 3 activated alumina, which has 40g / ft 3 Pt and 8g / ft 3 Pd's and 8g / ft 3Pd H-beta zeolite.

[0117] The coated LNT catalyst was placed on a flow-through monolithic substrate having a 152 in 3 (2.5L) capacity, a cell density of 400 cells per square inch and a wall thickness of approximately 100 μm. Primer contains 3.84g / in 3 Washcoat of activated alumina containing 10% ceria and 18% BaO, 1.1 g / in 3 Cerium oxide (87% of cerium oxide is in the form of particles), 0.24g / in 3 MgO and 0.096g / in 3 ZrO 2 . This base coat washcoat contains 34.3g / ft 3 Pt and 4.3g / ft 3 Pd. The top coat contains activated alumina which has 21.7 g / ft 3 Pt and 2.7g / ft 3 0.7g / in Pd 3 and with 7.0g / ft 3 Rh 0.5g / in 3 A washcoat of cerium oxide, substantially free o...

Embodiment 3

[0124] test

[0125] Pore samples were taken from each of the flow-through catalysts in Example 1 above. The individual well sample dimensions are 0.75"(D) x 0.42"(L) for DOC, 0.75"(D) x 1.25"(L) for LNT and 0.75"(D) x 0.75"(L) for SCR. Three sets of system samples were installed in a single experimental reactor. The distance between each catalyst component in the experimental reactor was 0.25 ". The exhaust system of Example 1 of the present invention (i.e. DOC+LNT+Cu-CHA and DOC+LNT+Cu-SAPO) and Comparative Example 2 (i.e. only DOC +LNT) aging alone. The aging process consists of two steps. First, the catalyst system is aged at 800° C. for 5 hours in flowing air with 10% water vapor. Then, the catalyst system is subjected to cyclic aging records, which Consists of a sulfation mode (loading 1 g S / L) at 300 °C and a desulfation mode (10 sec lean and 15 sec rich (λ = 0.9) cycle for 5 min) at 700 °C (LNT bed temperature). Cyclic aging was performed for 40 cycles. After agin...

Embodiment 4

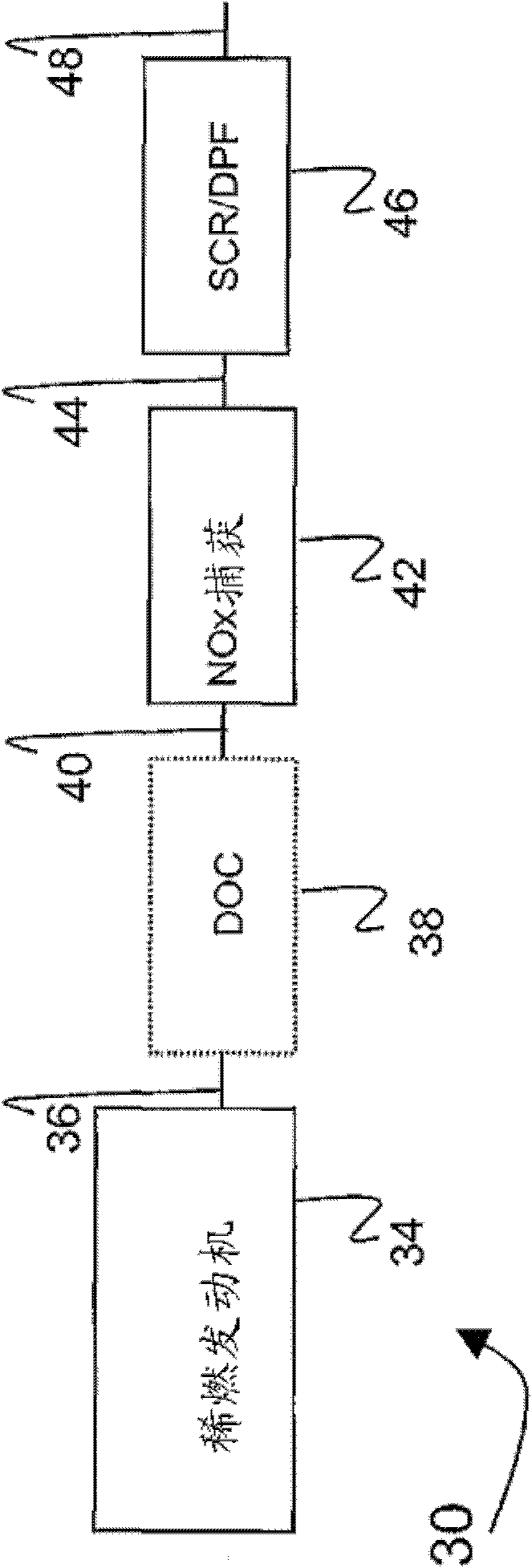

[0128] According to the method described herein, an exhaust system was formed by preparing an LNT catalyst with a 2-layer structure and an SCR catalyst comprising copper-SSZ-13 (CuCHA) on a diesel particulate filter (DPF).

[0129] The LNT catalyst was placed on a flow-through monolithic substrate having a 152in 3 (2.5L) capacity, a cell density of 400 cells per square inch, and a wall thickness of approximately 100 μm. The preparation of the LNT was substantially the same as described in Example 1 except for the PGM loading. The primer contains 63g / ft 3 Pt and 6.5g / ft 3 Pd, and the top coat has 40g / ft on activated alumina 3 Pt and 4g / ft 3 Pd and has 6.5g / ft on ceria 3 . The resulting coated LNT catalyst contains a total of 103 g / ft 3 Pt, 10.5g / ft 3 Pd and 6.5g / ft 3 Rh.

[0130] The CuCHA SCR catalyst was placed on a wall flow filter substrate with a 152in 3 (2.5L) capacity, a cell density of 300 cells per square inch, and a wall thickness of approximately 300 μm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com