Crystallization method for preparing high-purity idebenone

A technology for crystallization of idebenone, which is applied in the field of compound separation and purification, can solve the problems of low purity and low yield of idebenone, and achieve the effects of high purity and yield, simple operation and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

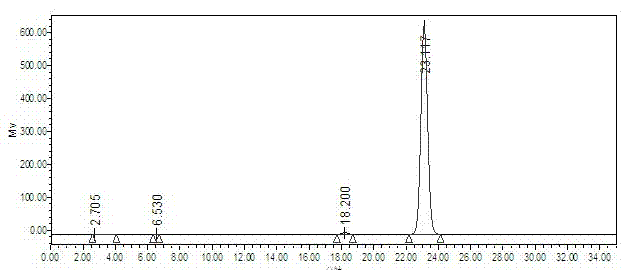

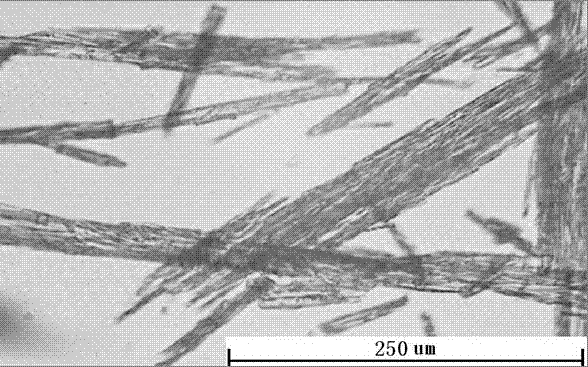

[0033] (1) Weigh 1.0 g of crude idebenone into a 200 mL jacketed glass crystallizer, measure 5 mL of dichloromethane with a graduated cylinder, and add it into the crystallizer at room temperature to completely dissolve idebenone. The temperature inside the crystallizer was controlled by a Julabo F32 refrigeration / heating circulating water bath, and the stirring was carried out by a Corning PC-353 magnetic stirrer. Then 35 mL of n-hexane was added to the crystallizer at room temperature, and the clear solution became cloudy. Heating the solution temperature to 36°C, the cloudy solution became clear. Filter the clarified liquid while it is hot, and place the filtrate in another 200 mL crystallizer. At this time, the temperature of the solution drops slightly, and then continue to heat to 36°C, keep the temperature constant for 30 minutes, and cool down to 0°C at a rate of 0.1°C / min. . As the temperature decreased, idebenone crystals slowly precipitated, filtered and washed (w...

Embodiment 2

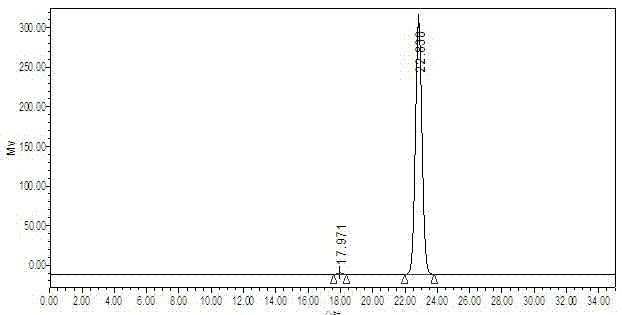

[0036](1) Weigh 1.2 g of crude idebenone into a 200 mL jacketed glass crystallizer, measure 6 mL of dichloromethane with a graduated cylinder, and add it into the crystallizer at room temperature to completely dissolve idebenone. The temperature inside the crystallizer was controlled by a Julabo F32 refrigeration / heating circulating water bath, and the stirring was carried out by a Corning PC-353 magnetic stirrer. Then 42 mL of n-hexane was added to the crystallizer at room temperature, and the clear solution became cloudy. Heating the solution temperature to 36°C, the cloudy solution became clear. Filter the clarified liquid while it is hot, and place the filtrate in another 200 mL crystallizer. At this time, the temperature of the solution drops slightly, and then continue to heat to 36°C, keep the temperature constant for 30 minutes, and cool down to 0°C at a rate of 0.1°C / min. . As the temperature decreased, idebenone crystals slowly precipitated, filtered and washed (wa...

Embodiment 3

[0039] (1) Weigh 1.6 g of crude idebenone into a 200 mL jacketed glass crystallizer, measure 8 mL of dichloromethane with a graduated cylinder, and add it into the crystallizer at room temperature to completely dissolve idebenone. The temperature inside the crystallizer was controlled by a Julabo F32 refrigeration / heating circulating water bath, and the stirring was carried out by a Corning PC-353 magnetic stirrer. Then 56 mL of n-hexane was added to the crystallizer at room temperature, and the clear solution became cloudy. Heating the solution temperature to 36°C, the cloudy solution became clear. Filter the clarified liquid while it is hot, and place the filtrate in another 200 mL crystallizer. At this time, the temperature of the solution drops slightly, and then continue to heat to 36°C, keep the temperature constant for 30 minutes, and cool down to 0°C at a rate of 0.1°C / min. . As the temperature decreased, idebenone crystals slowly precipitated, filtered and washed (w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com