Chemi-mechanical pulp waste liquid alkaline recycling pretreatment method

A chemical-mechanical pulp and pretreatment technology, which is applied in the field of alkali recovery of chemical-mechanical pulp waste liquid and alkali recovery pretreatment of chemical-mechanical pulp waste liquid, can solve problems affecting alkali recovery efficiency, environmental pollution, alkali waste, etc., and achieve alkali recovery High efficiency, reduced pollution, and improved alkali recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

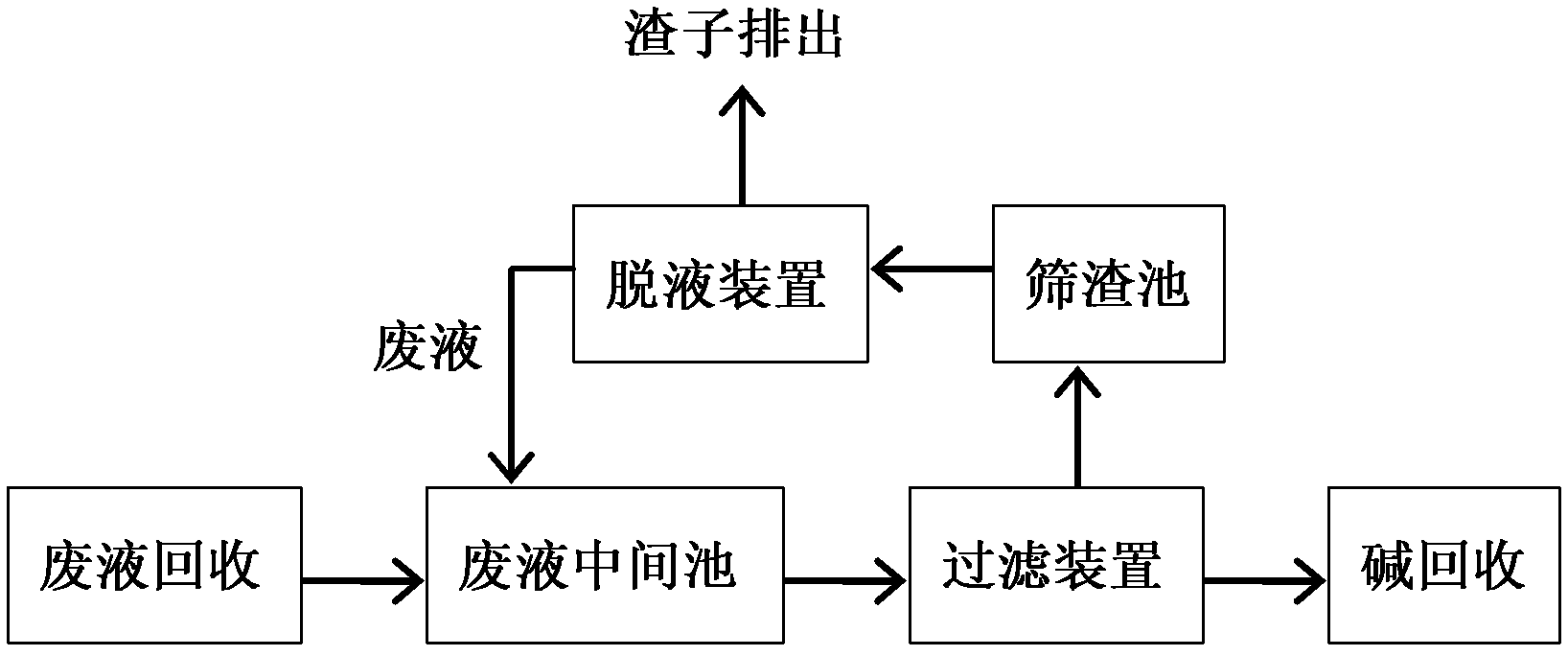

[0024] A method for alkali recovery and pretreatment of APMP chemical pulp waste liquid, comprising the following steps:

[0025] (1) Collect the waste liquid produced by the wood chip extruder during the APMP production process to the waste liquid intermediate pool, which is a square cement pool and placed next to the extruder.

[0026] (2) Pump the waste liquid in the middle pool to the fine grid for filtration, and the filtered waste residue flows into the slag pool, which is a square cement pool, placed under the fine grid, and the filtrate is sent to the alkali recovery tank Pre-evaporation section.

[0027] (3) Use a pump to send the slag in the sieve pool to the filter type centrifugal concentrator for dehydration treatment, control the quality of the detached slag to account for 70% of the total mass of the sieve, and return the waste water after the dehydration treatment to the middle of the waste liquid The pool; the slag that comes out is used as the core layer pul...

Embodiment 2

[0030] A method for alkali recovery and pretreatment of PRC-APMP chemical pulp waste liquid, comprising the following steps:

[0031] (1) Collect the waste liquid generated in the screw extrusion deflaker section and the screw press section in the PRC-APMP production process to the waste liquid intermediate pool, and at the same time collect the waste liquid generated in the subsequent screening section to the waste liquid intermediate pool. The middle pool is a circular steel tank, which is placed under the multi-disc filter in the screw press section.

[0032] (2) Pump the waste liquid in the intermediate pool to the F20 pressure screen for filtration, and the filtered waste residue flows into the slag pool, which is a circular steel tank, placed next to the pressure sieve, and the filtrate is sent to the alkali recovery tank Pre-evaporation section;

[0033] (3) The waste residue is sent to a sedimentation centrifugal concentrator for dehydration treatment. The quality of ...

Embodiment 3

[0036] A method for alkali recovery and pretreatment of CTMP chemical pulp waste liquid, comprising the following steps:

[0037] (1) Collect the waste liquid produced in the soaking section, screening section and concentration section in the CTMP production process to the waste liquid intermediate pool and the square cement tank in the intermediate pool;

[0038] (2) Pump the waste liquid in the intermediate pool to the pressure screen and the cone cleaner for twice filtration, and the filtered filtrate is sent to the alkali recovery evaporation section;

[0039] (3) The waste residue is sent to the screw press machine for dehydration treatment, and the waste water after the dehydration treatment is returned to the waste liquid intermediate pool; the quality of the extracted slag accounts for 90% of the total mass of the sieve residue, and the slag after the dehydration treatment is ground After the pulp machine is regrinded, it enters the pulp tank for recycling.

[0040] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com