Method for growing large area of layer-number-controllable graphene at low temperature through chemical vapor deposition (CVD) method by using polystyrene solid state carbon source

A solid carbon source, polystyrene technology, applied in gaseous chemical plating, coating, metal material coating process, etc., can solve the problems of small graphene area, many defects, poor crystal quality, etc., and achieve cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

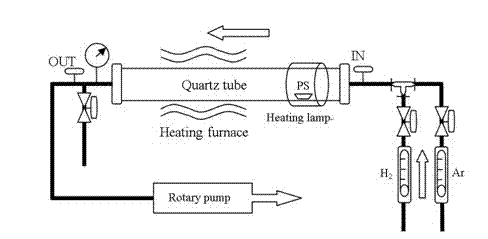

Method used

Image

Examples

Embodiment 1

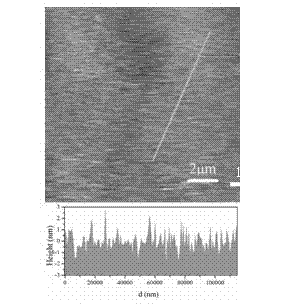

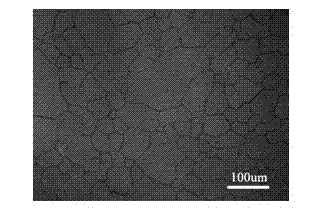

[0036] Example 1: Large-area single-layer graphene was grown at low temperature using a polystyrene solid carbon source.

[0037] (1) Cu is used as the substrate, and the surface of the copper substrate is treated by mechanical polishing and electrochemical polishing successively to make the surface roughness below 5nm; the mechanical polishing speed is 800 rpm. The electrochemical workstation was used as the polishing power supply, and the Ag / AgCl electrode was selected as the reference electrode; the electrochemical polishing solution was a mixture of 85% phosphoric acid and polyethylene glycol with a volume ratio of 3:1. The copper sheet to be polished is placed on the positive electrode, and the copper sheet is used as the negative electrode; the electrochemical polishing voltage is 1~2V, and the polishing time is 1800s;

[0038] (2) After electrochemical polishing, ultrasonically clean the copper foil with acetone for 10 minutes, then ultrasonically clean it with 25% hydr...

Embodiment 2

[0045] Embodiment 2: Increase the weight of the polystyrene solid carbon source in Embodiment 1 to 30 mg; then repeat the process of Embodiment 1.

[0046] Example results: the transmittance test shows that the transmittance of the graphene thin layer prepared at 600° C. by 30 mg of the solid source reaches 93.5%. for bilayer graphene. Optical photographs show that the large-area graphene chemically transferred onto the glass substrate does not have any macroscopic damage. It is a complete double-layer graphene with an area of 1cm*2cm.

Embodiment 3

[0047] Embodiment 3: Increase the weight of the polystyrene solid carbon source in Embodiment 1 to 45 mg. Then repeat the process of embodiment one.

[0048] Example results: the transmittance test shows that the transmittance of the graphene thin layer prepared at 600° C. by 45 mg of the solid source reaches 90.3%. for three-layer graphene. Optical photographs show that the large-area graphene chemically transferred onto the glass substrate does not have any macroscopic damage. It is a complete three-layer graphene with an area of 1cm*2cm.

[0049] By the implementation result of embodiment 1, embodiment 2 and embodiment 3, illustrate by controlling polystyrene solid carbon source weight

[0050] The low-temperature preparation of graphene with different layers has high reliability, and can guarantee the preparation of graphene with stable quality and controllable layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com