Denitration method for two-section microwave catalytic reaction bed

A microwave catalysis and reaction bed technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of high requirements for pipeline equipment, large consumption of reducing agents, low denitration efficiency, etc., and achieve production costs. Low, high conversion rate, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first stage of microwave catalytic reaction bed microwave catalytic direct decomposition of NO reaction.

[0025] The loaded catalyst is 5g of CuO-Cu-ZSM-5, the mass fraction of Cu in Cu-ZSM-5 is 5%, and the mass fraction of CuO in CuO-Cu-ZSM-5 is 40%.

[0026] The intake NO flow rate is controlled at 160ml / min, and the oxygen content is 5.88%.

[0027] The microwave power is automatically controlled to keep the catalyst bed temperature at 180°C, 300°C, and 380°C respectively, and the reaction pressure is normal pressure.

[0028] The results are shown in Table 1:

[0029] Table 1. Reaction results of different catalyst bed temperatures

[0030] serial number

[0031] Conclusion: When the catalyst bed temperature is 380 ℃, CuO-Cu-ZSM-5 has a significant effect of decomposing NO in the microwave catalytic reactor, and the NO conversion rate reaches 98.93%.

Embodiment 2

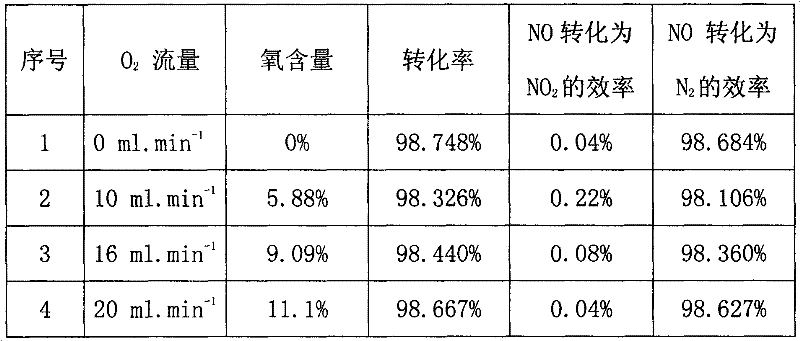

[0033] Effect of Oxygen Content on Microwave Catalytic Decomposition of NO.

[0034] Basically the same as in Example 1, except that the temperature of the catalyst bed was maintained at 300°C, the oxygen flow rate and content were changed, and the oxygen resistance of the catalyst in microwave catalytic decomposition of NO was investigated. The results are shown in Table 2.

[0035] Table 2. Effect of oxygen content on microwave catalytic decomposition of NO

[0036]

[0037] Among them, the imported NO content is 1000ppm. When oxygen exists, NO is almost completely converted into safe N 2 , the catalyst bed temperature is controlled at 300°C, and the NO conversion rate is above 98%; the oxygen content has no effect on the microwave catalytic decomposition NO conversion rate, and the catalyst has good oxygen resistance during microwave catalysis.

Embodiment 3

[0039] The second stage microwave catalytic reaction bed microwave catalytic reduction NO reaction.

[0040] Fill 10ml of activated carbon in the quartz reaction tube of a new microwave catalytic reactor, investigate the oxygen content and test the performance of Mn-modified activated carbon for catalytic reduction of NO under microwave. The effect of oxygen content on Mn / AC catalyst for microwave catalytic reduction of NO is shown in Table 3.

[0041] Reaction conditions: 3% Mn / AC filling volume 10ml, gas flow rate 160ml / min, nitrogen monoxide feed gas content 1000ppm, temperature 400°C.

[0042] Table 3. The effect of oxygen content on the catalytic reduction of NO by Mn-modified activated carbon under microwave

[0043] serial number

[0044] Conclusion: Oxygen content has no significant effect on the conversion of NO by microwave catalytic reduction of Mn / AC catalyst. The NO conversion rate can be as high as 99.72% through the microwave catalytic reduction reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com