Direct-feeding type asphalt warm-mix modifier as well as preparation method and application thereof

A modifier and drop-in technology, applied in building insulation materials, building components, climate change adaptation, etc., can solve the problems of single type of warm-mix modified asphalt, complicated preparation process, secondary pollution, etc., and achieve low price, Simple preparation process and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 7000g of waste recycled polyethylene with an average molecular weight of 1000, 2800g of ethylene bis stearamide and 500g of waste clay (the particle size of the waste clay is 300 mesh) into a screw extruder at 152°C for extrusion, and then The strip cutting equipment is cold-drawn and sheared, and then the prepared warm-mix asphalt modifier particles (trade name "asphalt") are put into a mixing tank with a mineral material temperature of 155°C and mixed for 10 seconds , and then add base asphalt and mix for 25 seconds to prepare a warm mix base asphalt mixture.

Embodiment 2

[0034] Add 8000g of waste recycled polyethylene with an average molecular weight of 900, 2500g of ethylene bisstearamide and 600g of diatomite with a particle size of 500 mesh into a screw extruder at a temperature of 150°C, and then pass through a strand cutting equipment Cold drawing, shearing and granulation, and then put the prepared warm-mix asphalt modifier granules (the brand name is "asphalt") into the mixing tank with the mineral material temperature at 150°C, mix for 15 seconds, and then add The base asphalt was mixed for 30 seconds to prepare a warm mix base asphalt mixture.

Embodiment 3

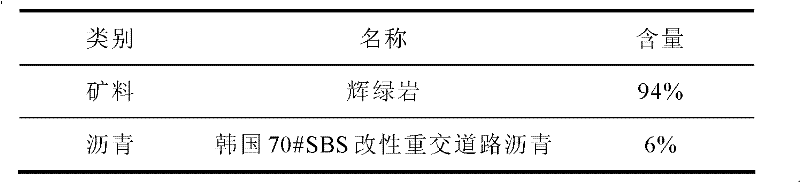

[0036] 7500g of waste recycled polypropylene with an average molecular weight of 1100, 4000g of ethylene bis stearamide and a specific surface area of 800m 2 / g, 1000g of powdered activated carbon with a particle size range of 200nm was added to a screw extruder, extruded at a temperature of 150°C, and then cold-stretched and sheared by a strand pelletizing device, and then the prepared warm Mix asphalt modifier particles (the brand name is "Bitumen") into the mixing tank with a mineral material temperature of 140 ° C, stir for 10 seconds, add SBS modified asphalt (SBS modified asphalt is based on base asphalt, A certain proportion of SBS modifier is added, and the SBS is uniformly dispersed in the asphalt by shearing, stirring, etc. to form a SBS blended material), and mixed for 20 seconds to obtain a warm-mixed SBS modified asphalt mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com