Ferrite/polyamide composite material and preparation method as well as application thereof

A composite material and polyamide technology, applied in the field of engineering plastics, can solve problems such as poor fluidity of composite materials, large loss of magnetic properties, and difficulty in injection molding processing, and achieve the effects of increased processing fluidity, low equipment requirements, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

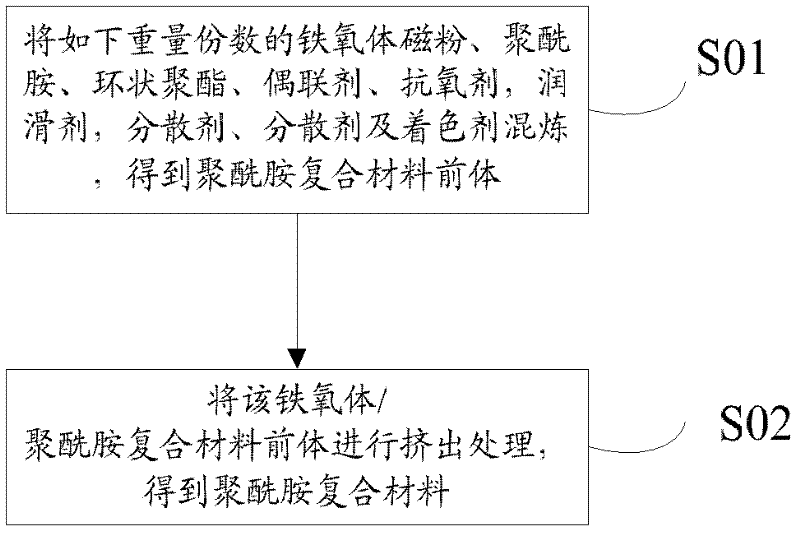

[0026] see figure 1 , figure 1 Show the flowchart of the preparation method of ferrite / polyamide composite material according to the embodiment of the present invention, including the following steps:

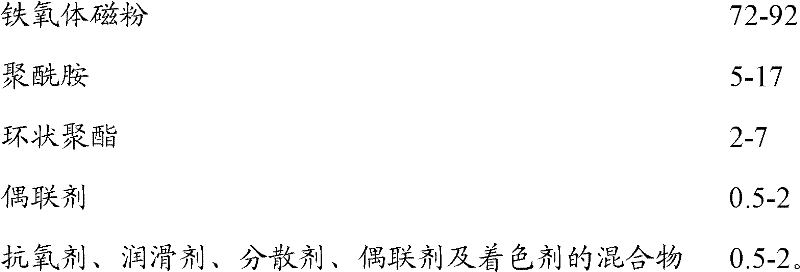

[0027] Step S01, mixing the following parts by weight of ferrite magnetic powder, polyamide, cyclic polyester, coupling agent, antioxidant, lubricant, dispersant, dispersant and colorant to obtain the polyamide composite material body;

[0028] Step S02, extruding the ferrite / polyamide composite material precursor to obtain a polyamide composite material,

[0029]

[0030] Specifically, the ferrite, polyamide, cyclic polyester, coupling agent, antioxidant, lubricant, dispersant, coupling agent, and colorant are the same as those described above, and will not be repeated here.

[0031] Specifically, in step S01, the equipment used in the mixing step is not limited, such as kneader, kneader, internal mixer, preferably internal mixer, the mixing time is 5-20 minutes, and the...

Embodiment 1

[0038] The ferrite / polyamide composite material in the embodiment of the present invention includes the following components in parts by weight:

[0039] 80 parts by weight of ferrite magnetic powder, 12 parts by weight of PA6 resin, 6 parts by weight of cyclic polyester, 1 part by weight of KH-570, 1 part by weight of antioxidant , Lubricant, dispersant and anti-ultraviolet agent mixture.

[0040] The preparation method of the polyamide composite material of the embodiment of the present invention comprises the following steps:

[0041] a, ferrite magnetic powder with 80 parts by weight, PA6 resin with 12 parts by weight, cyclic polyester with 6 parts by weight, KH-570 with 1 parts by weight, and 1 parts by weight with The mixture of antioxidant, lubricant, dispersant and anti-ultraviolet agent is put into an internal mixer and fully mixed for 15 minutes at a mixing temperature of 230°C to obtain a polyamide composite material precursor;

[0042]b, put the polyamide composi...

Embodiment 2

[0044] The ferrite / polyamide composite material in the embodiment of the present invention includes the following components in parts by weight:

[0045] 90 parts by weight of ferrite magnetic powder, 5 parts by weight of PA6 resin, 3 parts by weight of cyclic polyester, 1 part by weight of KH-570, 1 part by weight of antioxidant , Lubricant, dispersant and anti-ultraviolet agent mixture.

[0046] The preparation method of the ferrite / polyamide composite material in the embodiment of the present invention comprises the following steps:

[0047] a, 90 parts by weight of ferrite magnetic powder, 5 parts by weight of PA6 resin, 3 parts by weight of cyclic polyester, 1 part by weight of KH-570, 1 part by weight of The mixture of antioxidant, lubricant, dispersant and anti-ultraviolet agent was put into an internal mixer and fully mixed for 18 minutes at a mixing temperature of 235°C to obtain a polyamide composite material precursor;

[0048] b, put the polyamide composite mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com