Chitosan modified surface treatment liquid for galvanized color-coated board and preparation method thereof

A surface treatment liquid, chitosan modification technology, applied in the direction of metal material coating process, etc., can solve the problems of paint film adhesion, water resistance and brush resistance, and achieve low price, sufficient supply of raw materials, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

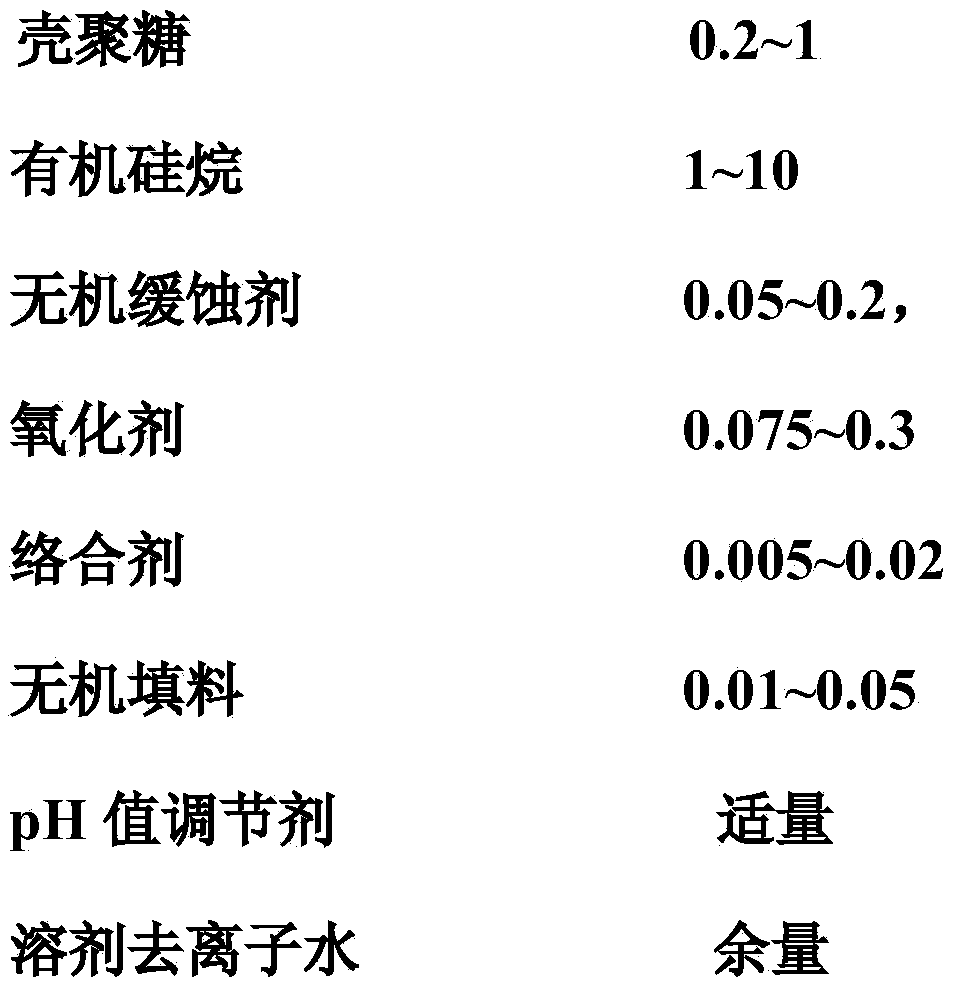

Method used

Image

Examples

Embodiment 1

[0031] Example 1: 6g of high viscosity chitosan (viscosity 1.2mp a ·S), 30g KH560 (γ-glycidoxypropyltrimethoxysilane), add 0.5g cerium nitrate hexahydrate, 0.75g 30% hydrogen peroxide, 0.05g boric acid, nano SiO 2 0.33g of dispersion (silica content 30wt%%) and the balance of deionized water and inorganic acid are prepared into 1000g surface treatment solution with a pH of 5-6.

Embodiment 2

[0032] Example 2: 6g of high viscosity chitosan (viscosity 1.2mp a ·S), 50g KH560 (γ-glycidoxypropyltrimethoxysilane), add 1g cerium nitrate hexahydrate, 1.5g 30% hydrogen peroxide, 0.1g boric acid, nano SiO 2 The dispersion liquid (silica content 30wt%%) 0.99g and the balance of deionized water and inorganic acid are formulated into 1000g surface treatment liquid with a pH of 5-6.

Embodiment 3

[0033] Example 3: 6g of high viscosity chitosan (viscosity 1.2mp a ·S), 70g KH560 (γ-glycidoxypropyltrimethoxysilane), add 2g cerium nitrate hexahydrate, 3g 30% hydrogen peroxide, 0.2g boric acid, nano SiO 2 Dispersion (silica content 30wt%%) 1.65g and the balance of deionized water and inorganic acid are formulated into 1000g surface treatment solution with a pH of 5-6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com