Exposure method adopting lithography machine

An exposure method and a lithography machine technology, which are applied in the field of lithography machine exposure, can solve the problems of production capacity decline, equipment utilization rate reduction, increase, etc., achieve good process registration accuracy, prevent silicon wafer deformation, and increase equipment utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

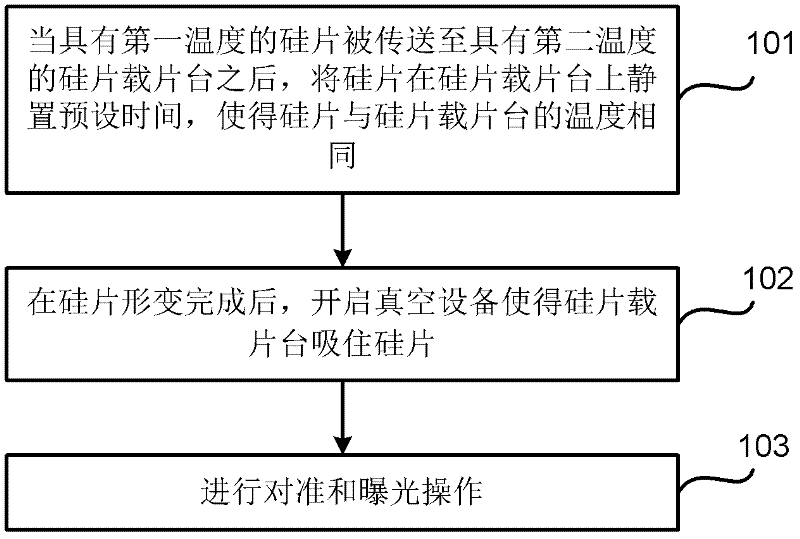

[0025] figure 1 An exemplary flow chart showing the exposure method of the lithography machine of the present invention includes the following steps 101-103 performed during the continuous operation of the lithography machine:

[0026] Step 101, after the silicon wafer with the first temperature is transferred to the silicon wafer loading table with the second temperature, the silicon wafer is placed on the silicon wafer loading table for a preset time, so that the silicon wafer and the silicon wafer loading table The temperature of the table is the same. The process of placing the silicon wafer on the silicon wafer stage for a preset time is equivalent to a process of temperature equilibrium, and the deformation of the silicon wafer is released during this proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com