External floating roof petroleum storage tank water mist safe protection system and protection method

A technology for oil storage tanks and safety protection, which is applied in the field of micro-water mist safety protection systems for oil storage tanks with external floating roofs. It can solve the problems of high transportation costs of liquid carbon dioxide, failure to reduce the ambient temperature of oil storage tanks, and splashing. Achieve the effect of reducing the explosion limit range, improving the active safety protection performance, and making it simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

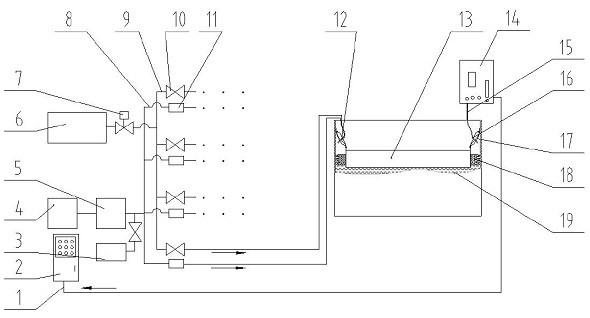

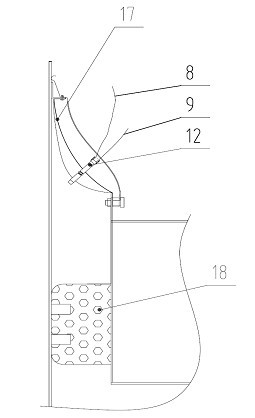

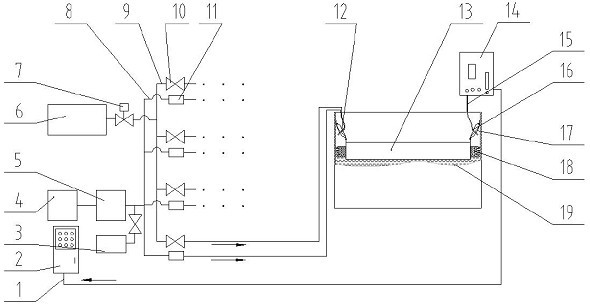

[0046] The specific structure of the active safety protection system for an external floating roof oil storage tank provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] Such as figure 1 and 2 As shown, a micro-water mist safety protection system for an external floating roof oil storage tank, in this embodiment, the system can protect the primary and secondary sealing spaces of one or more oil storage tanks at the same time. Petroleum 19 is housed in the tank, a primary seal 18 is provided between the petroleum and the floating roof 13 of the petroleum storage tank, and a secondary seal 17 is also provided on the top of the primary seal 18 . The micro-water mist safety protection system includes a control system placed outside the oil storage tank, a gas detection analyzer and an inert medium generation system. The control system is linked with the original fire alarm system of the oil storage center to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com