Oxidized sodium alginate/gelatin degradable hydrogel and preparation method thereof

A technology for oxidizing sodium alginate and hydrogel, which is applied in medical science, absorbent pads, bandages, etc., to achieve the effects of increased degradation rate, excellent absorbability, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

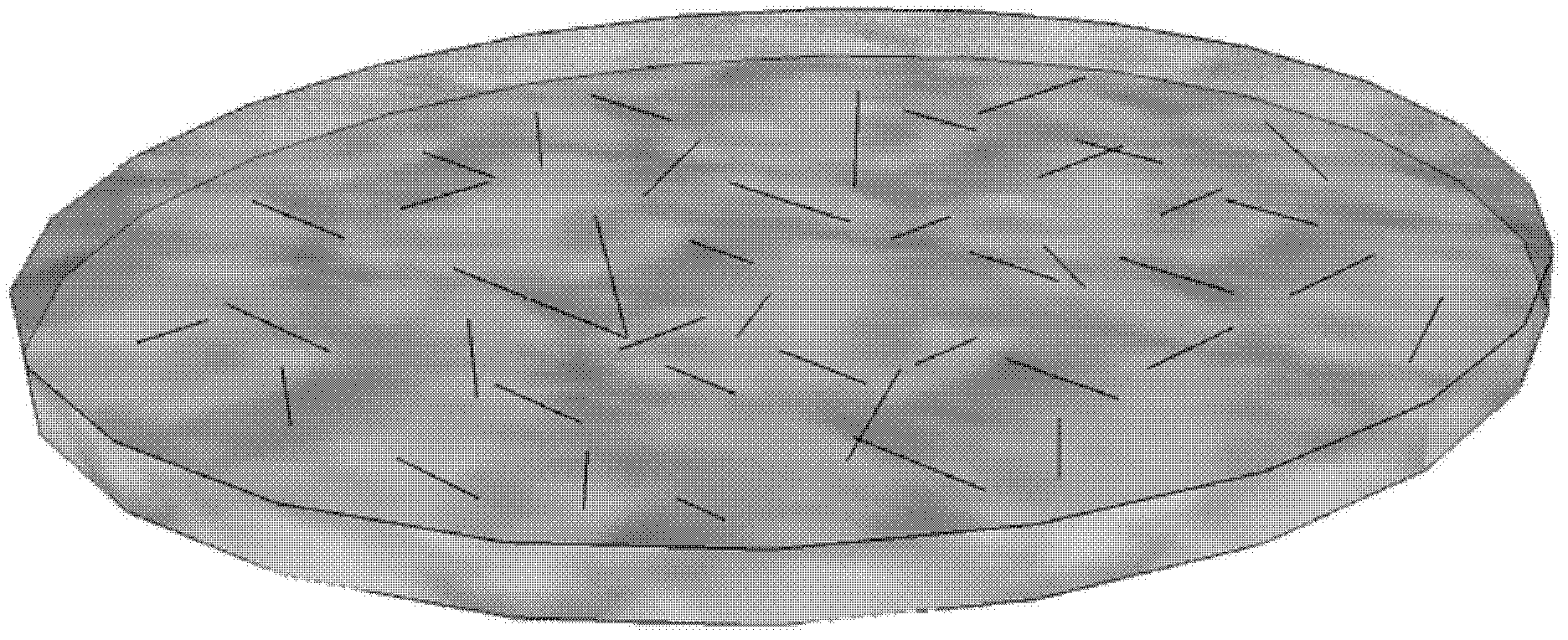

Image

Examples

Embodiment 1

[0032] (1) Take some PLA slices and dry them in a vacuum state at 100°C for 8 hours; then melt and extrude them through a screw extruder to obtain PLA primary multifilament fibers; after stretching, obtain PLA stretched fibers with a single filament diameter of 0.05mm, the number of multifilaments is 12; the fibers are cut into short fibers with an average length of 4mm.

[0033] (2) weigh sodium alginate with a balance and configure a solution with a mass fraction of 2% with distilled water; add potassium permanganate solution to make the concentration of potassium permanganate in the solution reach 5 × 10 -4 mol / L; use hydrochloric acid to adjust the pH of the solution to 3; stir in a dark room at room temperature for 10 minutes to fully oxidize; add 0.3% NaCl to the solution, and extract the oxidized sodium alginate with ethanol.

[0034] (3) Weigh gelatin with a balance and add it to distilled water, fully swell for 45 minutes, stir in a warm water bath at 60°C until compl...

Embodiment 2

[0038] (1) Take a number of PGLA slices and dry them under vacuum at 90°C for 15 hours; then melt and extrude them through a screw extruder to obtain PGLA primary single fibers; after stretching, obtain PGLA stretched single fibers with a diameter of 0.1 mm, the single fiber was cut into staple fibers with an average length of 3 mm long.

[0039] (2) weigh sodium alginate with a balance and configure a solution with a mass fraction of 2% with distilled water; add potassium permanganate solution to make the concentration of potassium permanganate in the solution reach 5 × 10 -4 mol / L; use hydrochloric acid to adjust the pH of the solution to 3; stir in a dark room at room temperature for 10 minutes to fully oxidize; add 0.3% NaCl to the solution, and extract the oxidized sodium alginate with ethanol.

[0040] (3) Weigh gelatin with a balance and add it to distilled water, fully swell for 45 minutes, stir in a warm water bath at 60°C until completely dissolved, and prepare a solut...

Embodiment 3

[0044] (1) Take a number of PBS slices and dry them under vacuum at 80°C for 10 hours; then melt and extrude them through a screw extruder to obtain PBS primary single fibers; after stretching, obtain PBS stretched single fibers with a diameter of 0.05 mm; the monofilaments were cut into short fibers with an average length of 4 mm long.

[0045] (2) weigh sodium alginate with a balance and configure a solution with a mass fraction of 2% with distilled water; add potassium permanganate solution to make the concentration of potassium permanganate in the solution reach 5 × 10 -4 mol / L; use hydrochloric acid to adjust the pH of the solution to 3; stir in a dark room at room temperature for 10 minutes to fully oxidize; add 0.3% NaCl to the solution, and extract the oxidized sodium alginate with ethanol.

[0046] (3) Weigh gelatin with a balance and add it to distilled water, fully swell for 45 minutes, stir in a warm water bath at 60°C until completely dissolved, and prepare a solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com