Reverse combustion biomass waste resource pyrolysis gasification heating equipment

A waste resource, pyrolysis gasification technology, applied in lighting and heating equipment, hot water central heating systems, heating methods, etc., can solve problems such as low utilization rate, achieve low manufacturing costs, solve domestic energy consumption, and reduce labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical means adopted by the present invention to achieve the intended purpose, the technical solutions proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

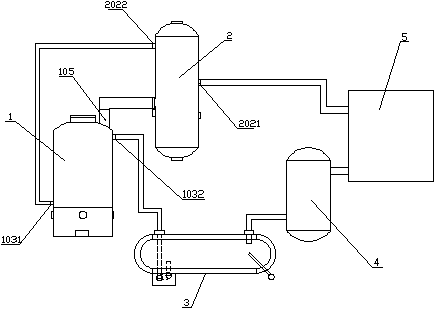

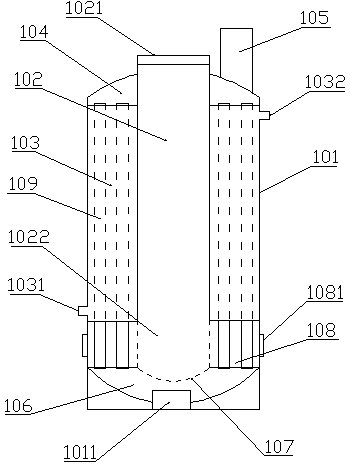

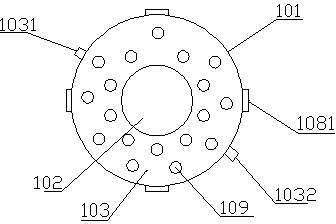

[0025] A counter-burning type biomass waste resource pyrolysis gasification heating equipment, including a counter-burning gasifier 1, a high-temperature biological mixed gas separator 2, a water storage buffer tank 3 and a boiler 4, and the part of the back-burning gasifier 1 The chimney 105 is connected to the high-temperature biological mixed gas separator 2, and a heat exchange chamber 103 is provided in the counter-burning gasifier, and a heat exchange chamber 202 is provided in the high-temperature biological mixed gas separator 2, and the heat exchange water outlet of the heat exchange chamber 202 is 2022 is connected to the water inlet 1031 of the heat exchange chamber 103, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com