Galvanized chromium-free black passivating agent and preparation method thereof

A technology of chrome black and acid regulator, which is applied in the coating process of metal materials, etc., can solve the problems of corrosion resistance and appearance without passivation of hexavalent chromium, high cost, difficult adjustment, etc., and achieve black and bright appearance, and waste water treatment Easy and strong corrosion resistance

Active Publication Date: 2012-04-18

DONGGUAN DONGHUI TRADE

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The common problems of the black passivation agents currently used in the market are that the cost is relatively high, and the stability of the passivation solution is difficult to control and difficult to adjust.

The chromium-free passivation solution provided by this invention can solve the problem of toxic and harmful hexavalent chromium and trivalent chromium elements contained in the existing product zinc coating and passivation solution, but the produced products cannot reach the level of chromium containing hexavalent chromium. The black and bright effect of the chromium passivator, the corrosion resistance is not outstanding enough

[0009] Chromium-free passivation systems include titanates, molybdates, tungstates, rare earths, and silicates. Although these chromium-free passivation systems are non-toxic and environmentally friendly, their corrosion resistance and appearance are not as good as hexavalent chromium passivation systems. , cannot meet the electroplating requirements of ordinary hardware, let alone meet the high corrosion resistance requirements of auto parts electroplating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

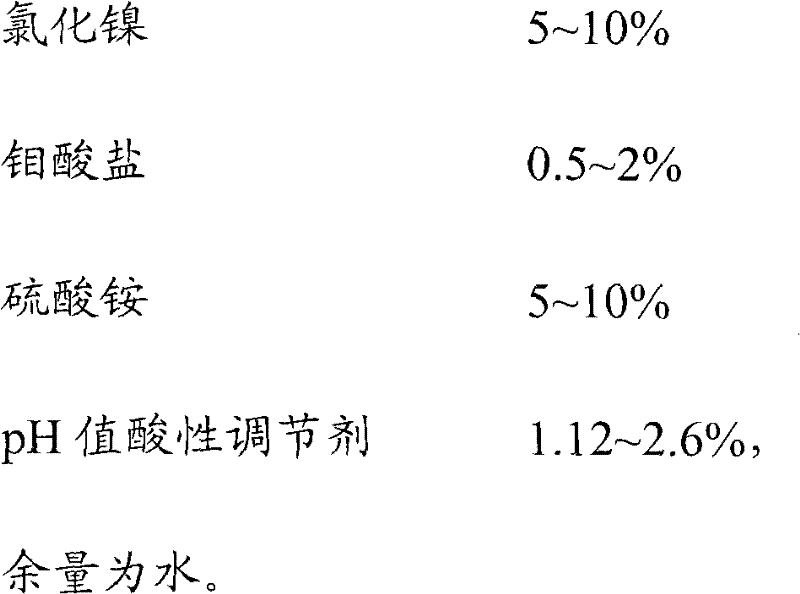

[0039] A chrome-free black passivator for galvanizing, comprising the following components by mass fraction:

[0040]

Embodiment 2

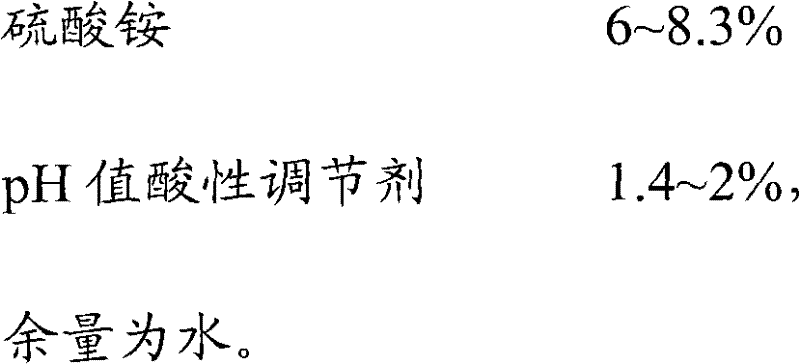

[0042]

[0043]

Embodiment 3

[0045]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a galvanized chromium-free black passivating agent and a preparation method thereof. The galvanized chromium-free black passivating agent comprises the components such as nickelous chloride, molybdate, ammonium sulphate, a pH acid regulator, water and the like. The preparation method comprises the following steps of: operating the black passivating agent at the operation temperature of 20-40DEG C and the pH value of 4.0-5.0 for 0.5-1.5 minutes; preparing materials according to the mass fraction of various components; adding 50-70 percent of water in the raw materials into a stirring device; sequentially feeding other components; finally, adding residual water; and stirring for at least five minutes to obtain a finished product. The galvanized chromium-free black passivating agent has no hexavalent chrome and trivalent chromium, is suitable for black passivation of galvanized parts, can obtain a glossy black effect same as the passivation of the hexavalent chrome and the trivalent chromium and can meet the requirement of products. Before the galvanized chromium-free black passivating agent is dried, workpieces are not easily ground; and the passivated galvanized chromium-free black passivating agent is glossily black without being closed. The galvanized chromium-free black passivating agent has the advantages of strong corrosion resistance, no pollution, easiness in wastewater treatment and simpliness in operation.

Description

technical field [0001] The invention belongs to the field of post-processing of galvanizing, and in particular relates to a chromium-free black blunt agent for galvanizing and a preparation method thereof. Background technique [0002] Passivator is a chemical agent that forms a dense oxide film (passive film) on the metal surface under certain conditions to enhance the anti-corrosion ability of the metal. In the passivation of metals, the passivation of the galvanized layer occupies a special position due to its wide range, large quantity and strict requirements, and has attracted more and more attention from the industry and the whole society. At present, galvanized products at home and abroad still use chromate passivation. In recent years, this traditional use mode has been severely challenged and replaced by specialized production of passivators. Its composition and concentration are developing towards high quality, high stability and low toxicity, and substantial pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C22/40

Inventor 雷鑫梁纪元梁尹琦戴华玉李洪胡常兰

Owner DONGGUAN DONGHUI TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com