Epitaxial method for improving luminous efficiency of GaN-based LED (Light Emitting Diode)

A technology of luminous efficiency and epitaxial growth, applied in chemical instruments and methods, crystal growth, electrical components, etc., can solve problems such as lattice constant and thermal expansion coefficient mismatch, affecting the internal quantum efficiency of materials, etc., to reduce the impact and improve the internal The effect of quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

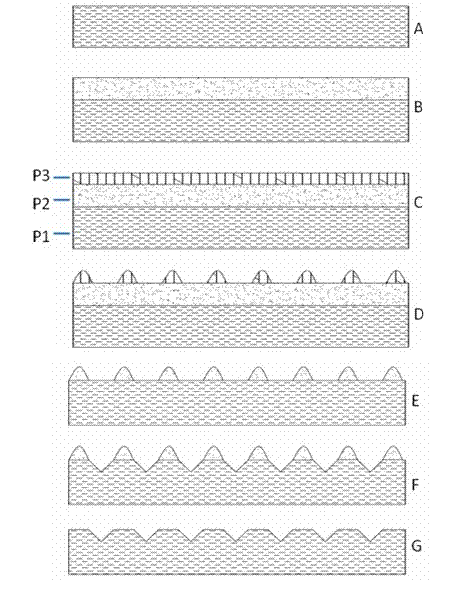

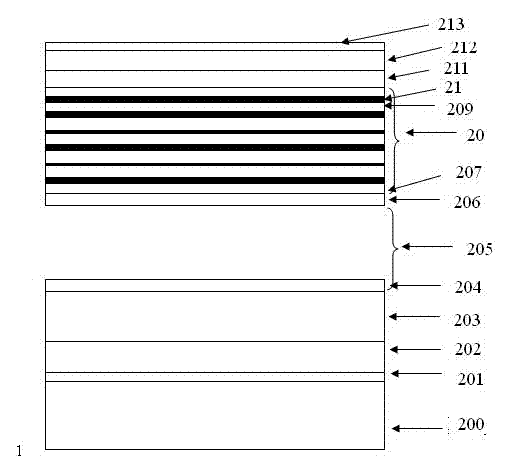

[0014] 1) Place the sapphire substrate 200 with (0001) crystal orientation on a graphite disk and send it into the reaction chamber, heat the sapphire substrate to 1060°C for 5 minutes.

[0015] 2) Lower the temperature to 540° C. to grow a low-temperature buffer layer 201 with a thickness of about 30-70 nm.

[0016] 3) Raise the temperature to 1020°C to grow a nucleation layer with a thickness of about 100-300nm.

[0017] 4) Raise the temperature to 1080° C. to grow an undoped GaN layer 202 with a thickness of about 1 μm.

[0018] 5) Growing a Si-doped nGaN layer 203 with a thickness of about 1.7um.

[0019] 6) Lower the temperature to 850° C. to grow a Si-doped n-type current spreading layer 204 with a thickness of about 40 nm.

[0020] 7) Treat the surface of the n-type current spreading layer by injecting SiH4 at 700° C. for 10 seconds 205 .

[0021] 8) Grow the nucleation layer for 20s with a growth pressure of 600Torr.

[0022] 9) Grow a Si-doped nGaN surface recover...

Embodiment 2

[0029] 15) Place the sapphire substrate with (0001) crystal orientation on a graphite disk and send it into the reaction chamber, heat the sapphire substrate to 1060°C for 5 minutes.

[0030] 16) Lower the temperature to 540°C to grow a low-temperature buffer layer with a thickness of about 30-70nm.

[0031] 17) Raise the temperature to 1020°C to grow a nucleation layer with a thickness of about 100-300nm.

[0032] 18) Raise the temperature to 1080°C to grow an undoped GaN layer about 1um thick.

[0033] 19) Grow a Si-doped nGaN layer about 1.7um thick.

[0034] 20) Lower the temperature to 850°C to grow a Si-doped n-type current spreading layer with a thickness of about 40nm.

[0035] 21) Heat up to 900°C and pass H2 for 10 minutes to treat the surface of the n-type current spreading layer.

[0036] 22) Grow the nucleation layer for 20s with a growth pressure of 600Torr.

[0037] 23) Grow a Si-doped nGaN layer with a thickness of about 50?, and the growth pressure is 100T...

Embodiment 3

[0044] 29) Place the sapphire substrate with (0001) crystal orientation on a graphite disk and send it into the reaction chamber, heat the sapphire substrate to 1060°C for 5 minutes.

[0045] 30) Lower the temperature to 540°C to grow a low-temperature buffer layer with a thickness of about 30-70nm.

[0046] 31) Raise the temperature to 1020°C to grow a nucleation layer with a thickness of about 100-300nm.

[0047] 32) Raise the temperature to 1080°C to grow an undoped GaN layer about 1um thick.

[0048] 33) Grow a Si-doped nGaN layer about 1.7um thick.

[0049] 34) Lower the temperature to 850°C to grow a Si-doped n-type current spreading layer with a thickness of about 40nm.

[0050] 35) Raise the temperature to 1100°C and pass CH4 for 20 minutes to treat the surface of the n-type current spreading layer.

[0051] 36) Grow the nucleation layer for 20s, and the growth pressure is 600Torr.

[0052] 37) Grow a Si-doped nGaN surface recovery layer about 50? thick with a grow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com