High strength and completely antioxidative third generation monocrystalline high temperature alloy and preparation method thereof

A superalloy and anti-oxidation technology, applied in the field of third-generation single crystal superalloy and aero-engine blade materials, can solve the problems of unstable microstructure and high cost, achieve easy control of solution treatment, good high temperature strength, low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

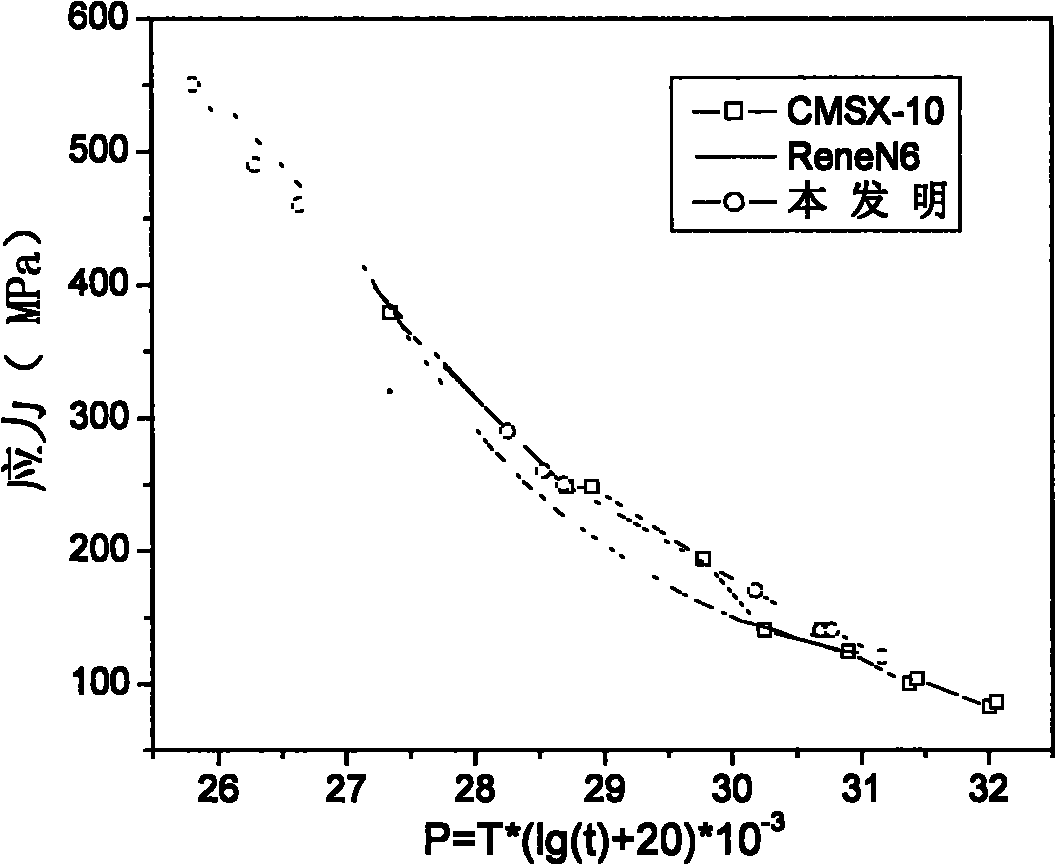

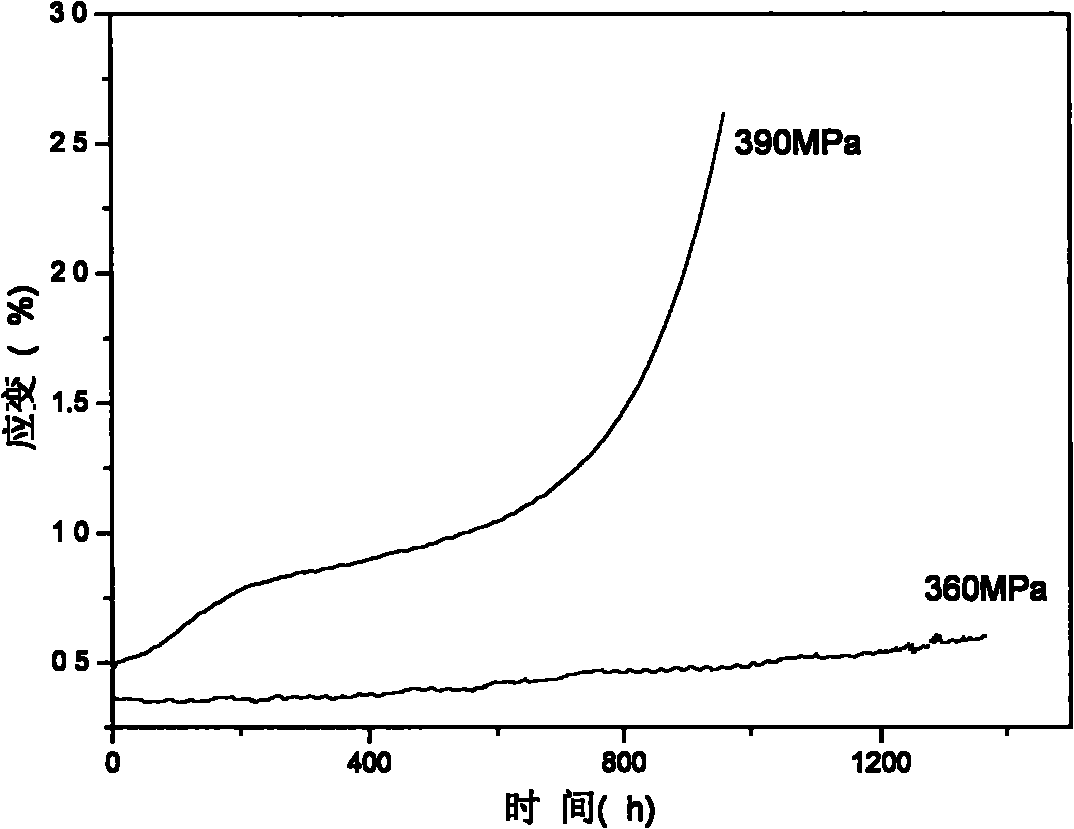

[0042] The specific composition of the alloy of the present invention is shown in Table 1. For the convenience of comparison, the chemical composition of CMSX-4 and CMSX-10 is also listed in Table 1.

[0043]Table 1 The chemical composition (wt%) of the embodiment of the present invention and comparative alloy CMSX-4 and CMSX-10

[0044]

[0045] After batching and vacuum induction melting according to the alloy composition, it is cast into a master alloy ingot with a size of φ80×500mm, then polished to remove scale, and cut into suitable blocks for preparing single crystal rods.

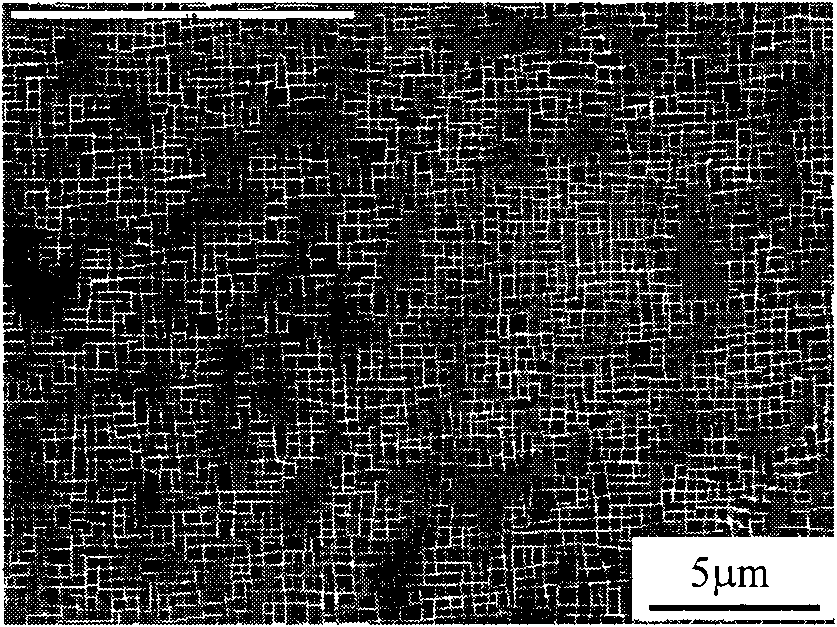

[0046] The single crystal rod is prepared in a directional solidification furnace by the spiral crystal selection method. The temperature gradient of the single crystal growth furnace is 60K / cm, the pouring temperature is 1550°C, and the shell temperature is kept consistent with the pouring temperature; after standing for 10 minutes, pull with a predetermined single crystal growth rate of 5mm / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com