Denim printing and dyeing technology with printing and sprinkling effect

A printing and dyeing process, denim technology, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of sewage discharge on the environment, long process route, difficult quality control, etc., to improve product style, rich colors, reduce waste water. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: A denim printing and dyeing process with printing and spraying effects. The gray fabric used is elastic denim knitted fabric, and the selected pattern is thin-neck letters filled with bottom scraping printing. Since the thin-neck letters require clear and fine, it is selected Pigment printing plus scraping printing, printing with sulfur dyes, has the following steps:

[0027] A. Pre-treatment gray cloth: Treat the gray cloth with alkali, refining agent and hydrogen peroxide, and dehydrate and shape it.

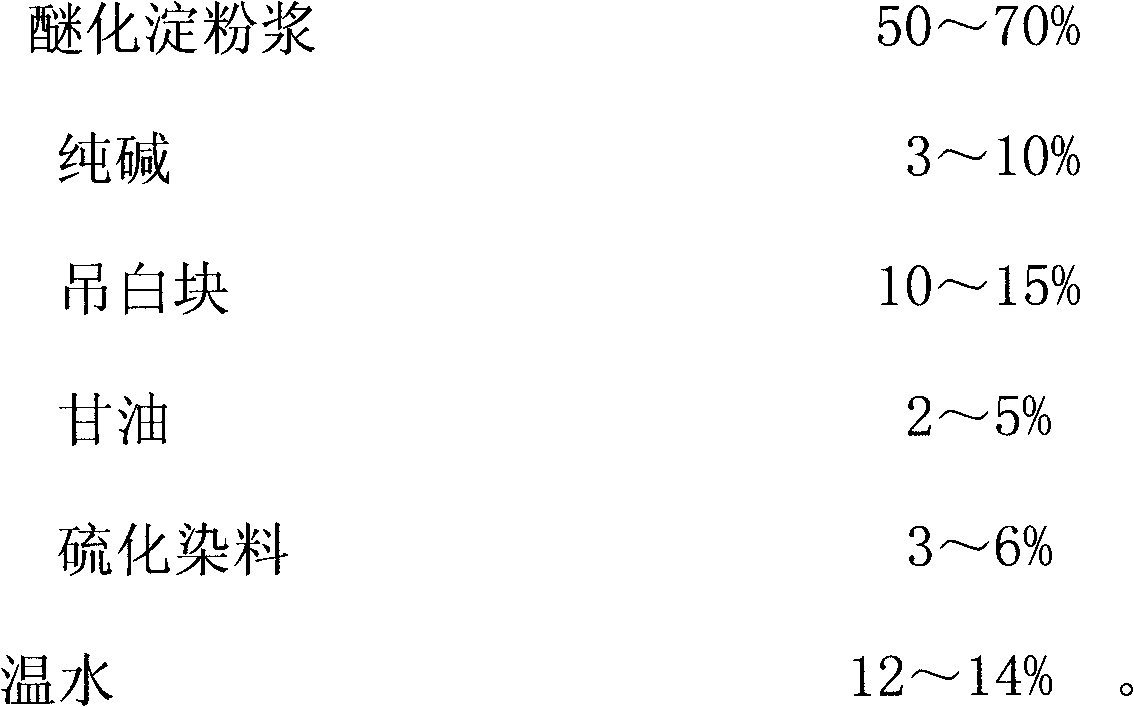

[0028] B. Printing: mixing paste ① pigment printing paste; ② sulfur dye printing paste. Scrape printing paint color paste first, then scrape printing sulfur dye printing color paste, flat screen printing, drying, the temperature of the machine printing drying room is 110 ℃.

[0029] C. Steaming: continuous steaming, temperature 102°C, time 6 minutes.

[0030] D. Water washing: use a continuous rope washing machine, use cold water for the first three steps, ...

Embodiment 2

[0040] A denim printing and dyeing process with printing and spraying effects. The gray fabric used is elastic denim. The pattern with more color registration is selected. In order not to affect the hand feeling and meet the requirements of rich colors, vat dyes are used for pattern printing. , the large scraping bottom is printed with sulfur dyes, which specifically includes the following steps:

[0041] A. Pre-treatment gray cloth: Treat the gray cloth with alkali, refining agent and hydrogen peroxide, and dehydrate and shape it.

[0042] B. Printing: Sizing ① vat dye printing paste; ② sulfur dye printing paste, flat screen printing, drying, machine printing drying room temperature is 115 ℃.

[0043] C. Steaming; the continuous steaming temperature is 100°C and the time is 8 minutes.

[0044] D, water washing; select continuous rope washing machine, the first three with cold water, the fourth with 75 ℃ hot water, the last two with cold water, centrifuge dehydration.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com