Multielement composite cathode material for lithium secondary battery and preparation method thereof

A lithium secondary battery, multi-component composite technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of high-temperature gas swelling and incomplete reaction of ternary positive electrode materials, improve cycle performance and thermal stability performance, improve Structural stability, low inflation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

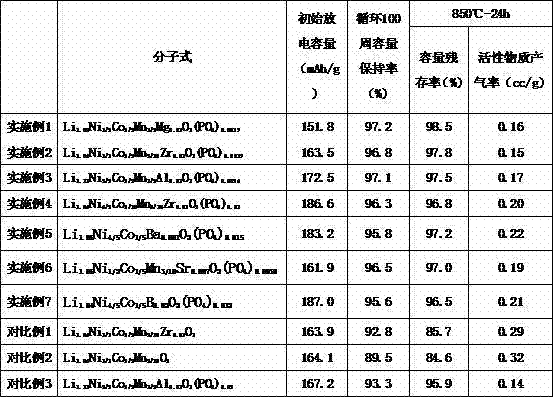

[0020] The lithium secondary battery of the present embodiment is used multi-component composite cathode material, and its chemical formula is Li 1.08 Ni 2 / 5 co 1 / 5 mn 2 / 5 Mg 0.01 o 2 (PO 4 ) 0.0027 , in powder form.

[0021] Its preparation method:

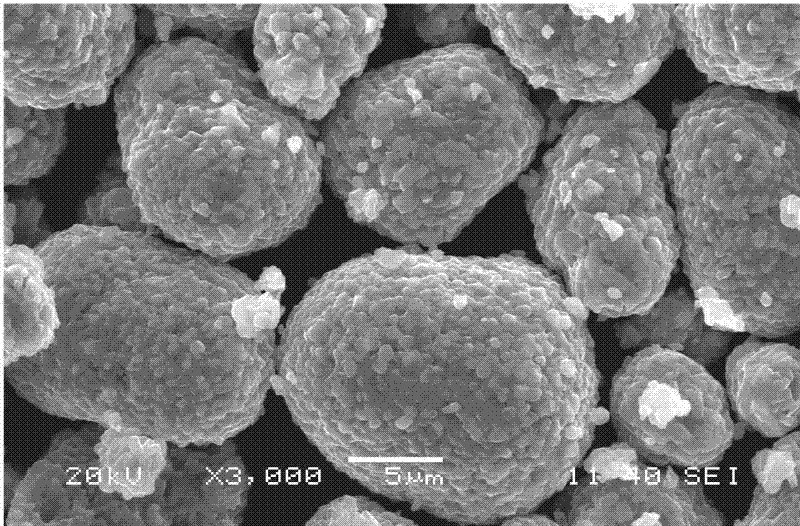

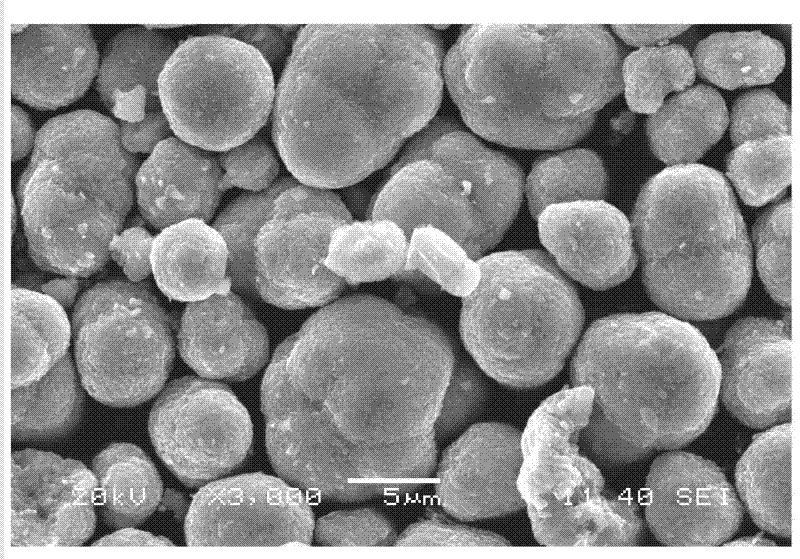

[0022] (1) Weigh Ni 2 / 5 co 1 / 5 mn 2 / 5 (OH) 2 Represented nickel-cobalt-manganese compound (average particle size D50=10.0μm measured by laser particle size analyzer, tap density 2.05g / cm 3 , spherical powder particles) 280.00g, lithium carbonate 122.19g and magnesium carbonate 2.57g, dry mixed, placed in a muffle furnace, and then sintered at 900°C for 10h, cooled, crushed, sieved, and the chemical formula is Li 1.08 Ni 2 / 5 co 1 / 5 mn 2 / 5 Mg 0.01 o 2 represented by Compound A;

[0023] (2) The Li was measured by acid-base titration 1.08 Ni 2 / 5 co 1 / 5 mn 2 / 5 Mg 0.01 o 2 The residual lithium element content of material is 658ppm, weighs 200g above-mentioned synthetic Li 1.08 Ni 2 / 5 co 1 / 5 mn 2 / 5 Mg 0.01 ...

Embodiment 2

[0026] The lithium secondary battery of the present embodiment is used multi-component composite cathode material, and its chemical formula is Li 1.04 Ni 1 / 2 co 1 / 5 mn 3 / 10 Zr 0.01 o 2 (PO 4 ) 0.0017 , in powder form;

[0027] Its preparation method:

[0028] (1) Weigh Ni 1 / 2 co 1 / 5 mn 3 / 10 (OH) 2 Represented nickel-cobalt-manganese compound (average particle size D50=8.0μm measured by laser particle size analyzer, tap density 1.60g / cm 3, powder particle shape similar to spherical) 280.00g, lithium carbonate 116.89g, zirconia 3.74g, dry mixing, placed in a muffle furnace, and then sintered at 850°C for 20h, cooled and crushed, sieved, and the chemical formula is Li 1.04 Ni 1 / 2 co 1 / 5 mn 3 / 10 Zr 0.01 o 2 represented by Compound A;

[0029] (2) The Li was measured by acid-base titration 1.04 Ni 1 / 2 co 1 / 5 mn 3 / 10 Zr 0.01 o 2 The residual lithium element content of the material is 451ppm, weigh 200g of the above-mentioned synthesized Li 1.04 Ni 1 / 2 co 1...

Embodiment 3

[0032] The lithium secondary battery of the present embodiment is used multi-component composite cathode material, and its chemical formula is Li 1.12 Ni 3 / 5 co 1 / 5 mn 1 / 5 al 0.01 o 2 (PO 4 ) 0.0054 , in powder form.

[0033] Its preparation method:

[0034] (1) Weigh Ni 3 / 5 co 1 / 5 mn 1 / 5 (OH) 2 Represented nickel-cobalt-manganese compound (average particle diameter D50=13.5μm measured by laser particle size analyzer, tap density 2.25g / cm 3 , powder particle shape similar to spherical) 280.00g, lithium carbonate 125.07g and alumina 1.54g, dry mixed, placed in a muffle furnace, then sintered at 750°C for 20h, cooled, crushed, sieved, and the chemical formula is Li 1.12 Ni 3 / 5 co 1 / 5 mn 1 / 5 al 0.01 o 2 represented by Compound A;

[0035] (2) The Li was measured by acid-base titration 1.12 Ni 3 / 5 co 1 / 5 mn 1 / 5 al 0.01 o 2 The residual lithium element content of the material is 1221ppm, weigh 200g of the above-mentioned synthesized Li 1.12 Ni 3 / 5 co 1 / 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com