Superfine shrimp shell powder high-calcium sausage and preparation method thereof

A technology for shrimp shell powder and meat sausage, which is applied in food preparation, food science, application and other directions, can solve the problems of not further improving the comprehensive utilization rate of hairy shrimp, the inability to fully emulsify the meat sausage, and the difficulty in controlling the temperature of chopping and mixing. Improve the comprehensive utilization rate and added value, improve the comprehensive utilization rate, increase the effect of adsorption and biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Materials and methods

[0046] 1.1 Materials and reagents

[0047] For shrimp heads and shells, the manufacturer is Rizhao Yuzheng Aquatic Products Co.;

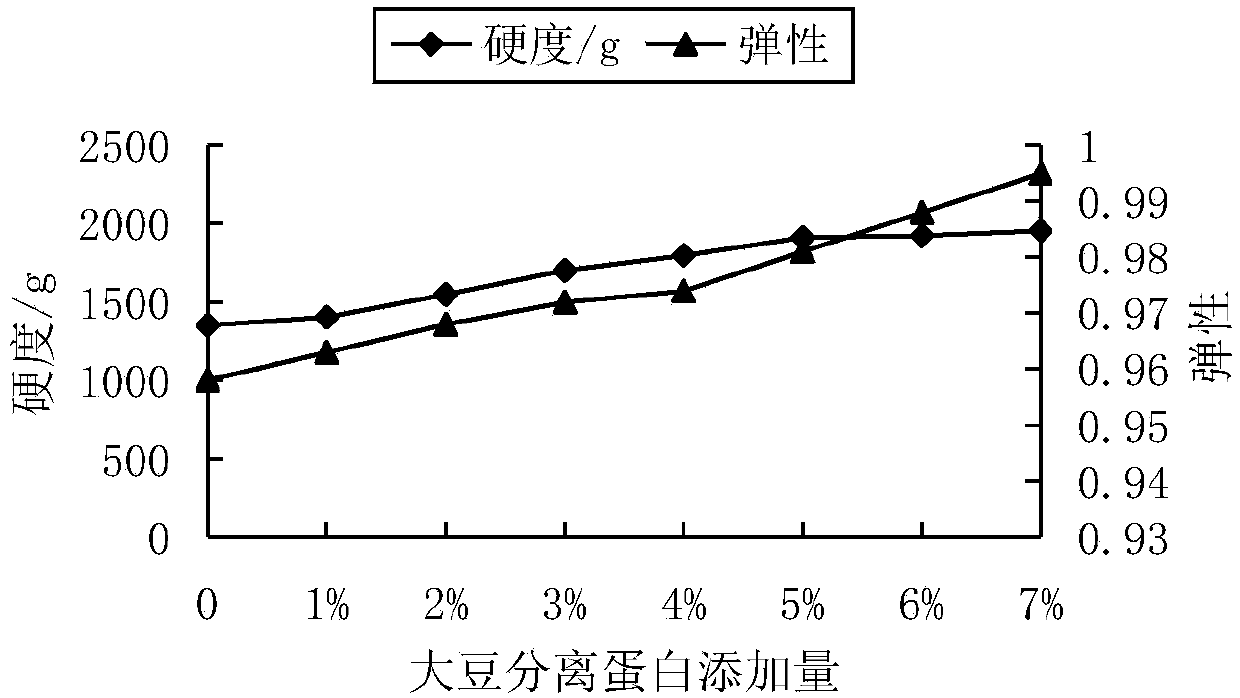

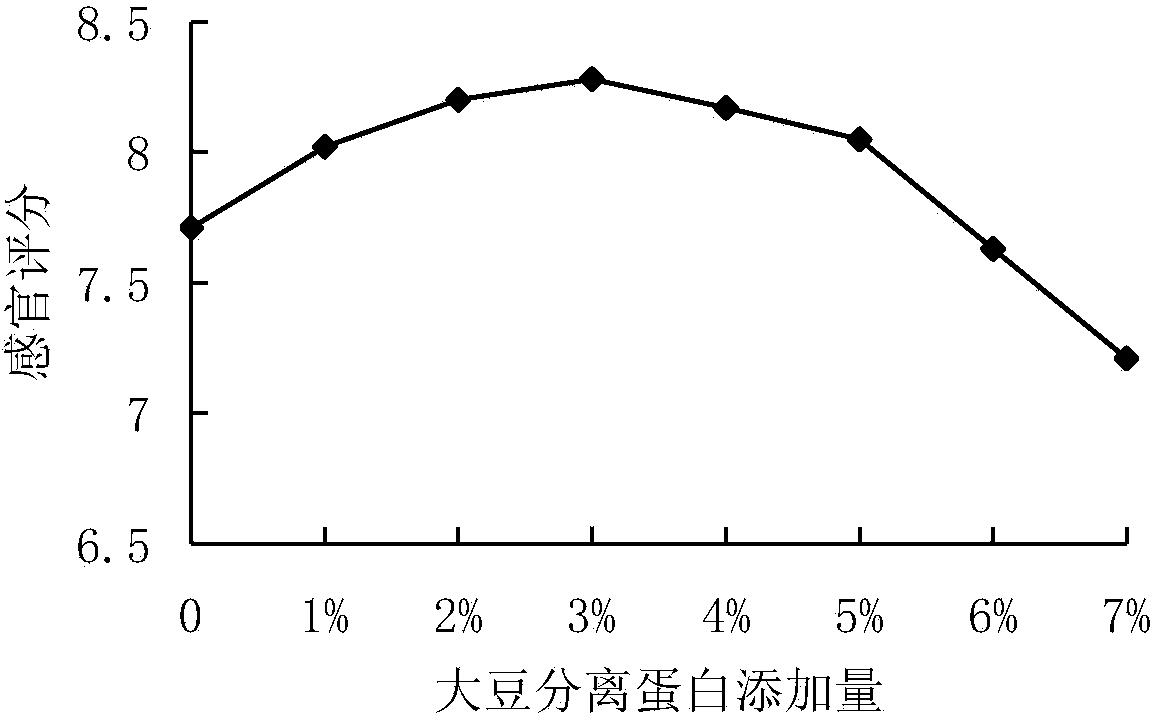

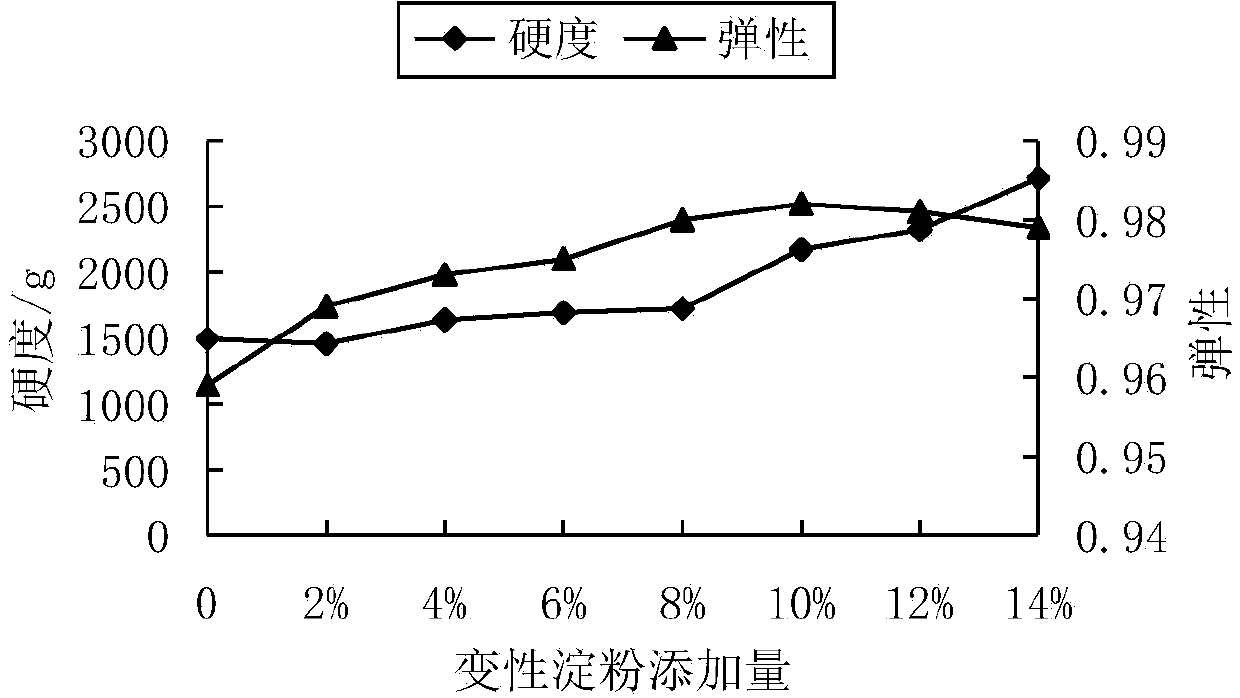

[0048] Fresh pork (pig ham and pork loin fat), ice water, natural casing, salt, white sugar, soybean protein isolate, modified starch, complex phosphate, carrageenan, sodium nitrite, ethyl maltol, spices (garlic Powder, pepper and monosodium glutamate) are commercially available; other reagents are of analytical grade.

[0049] 1.2 Instruments and equipment

[0050] WZJ6 ultrafine pulverizer Jinan Beili Powder Technology Engineering Co., Ltd.; SZ-18 meat grinder, CG-II sausage filling machine, ZB-20L high-speed chopping machine Zhucheng Hengtai Machinery; BVBJ-30F vacuum mixer Hangzhou Aibo Machinery; TA -XT Plus Texture Analyzer British Stable Micro System Company; TGL-16 Desktop High-speed Refrigerated Centrifuge Hunan Xiangyi Centrifuge Instrument Co., Ltd.; TAS-990 Atomic Absorption Spectrophotometer, TU-195...

Embodiment 2

[0089] The preparation method is the same as that of Example 1, but the ratio of main raw materials is different.

[0090] Superfine shrimp shell powder high-calcium meat sausage is made of the following raw materials by weight after processing and filling with natural casings. The raw material ratio is: 700 parts of pork hind leg meat, 20 parts of pork loin fat; 1 part of salt; 1 part of sugar; 1 part of soybean protein isolate; 4 parts of modified starch; 1 part of superfine shrimp shell powder; 0.1 part of compound phosphate; 0.1 part of carrageenan; 0.1 part of spice; 20 parts of ice water. The ultra-fine shrimp shell powder is made by pulverizing the edible prawn heads and shells that meet the legal requirements through a superfine pulverizer, and the mass percentage of fine particles with a particle size of 300 mesh in the ultra-fine shrimp shell powder exceeds 95%. The spices consist of garlic powder, pepper powder and monosodium glutamate in a mass ratio of 3:1:0.035. ...

Embodiment 3

[0092] The preparation method is the same as that of Example 1, but the ratio of main raw materials is different.

[0093] Superfine shrimp shell powder high-calcium sausage is made of the following raw materials by weight after processing and filling with natural casings. The ratio of raw materials is: 100 parts of pork hind leg meat, 30 parts of pork loin fat; 4 parts of salt; 4 parts of sugar; 5 parts of soybean protein isolate; 8 parts of modified starch; 3 parts of superfine shrimp shell powder; 0.5 part of compound phosphate; 0.6 part of carrageenan; 0.03 part of sodium nitrite; ; 60 parts of ice water.

[0094] The ultra-fine shrimp shell powder is made by pulverizing the edible prawn heads and shells that meet the legal requirements through a superfine pulverizer, and the mass percentage of fine particles with a particle size of 300 mesh in the ultra-fine shrimp shell powder exceeds 95%.

[0095] The spices consist of garlic powder, pepper powder and monosodium glutam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com