Blast furnace gas washing deacidification apparatus and method thereof

A technology of blast furnace gas and coal gas, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., and can solve the problems of abnormal operation of pressure reducing valves and other components, safety hazards of blast furnace gas and gas pipelines, and cavitation and cracking of compensators, etc. problem, to achieve the effects of small footprint, small heat loss, and prevention of electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Equipment

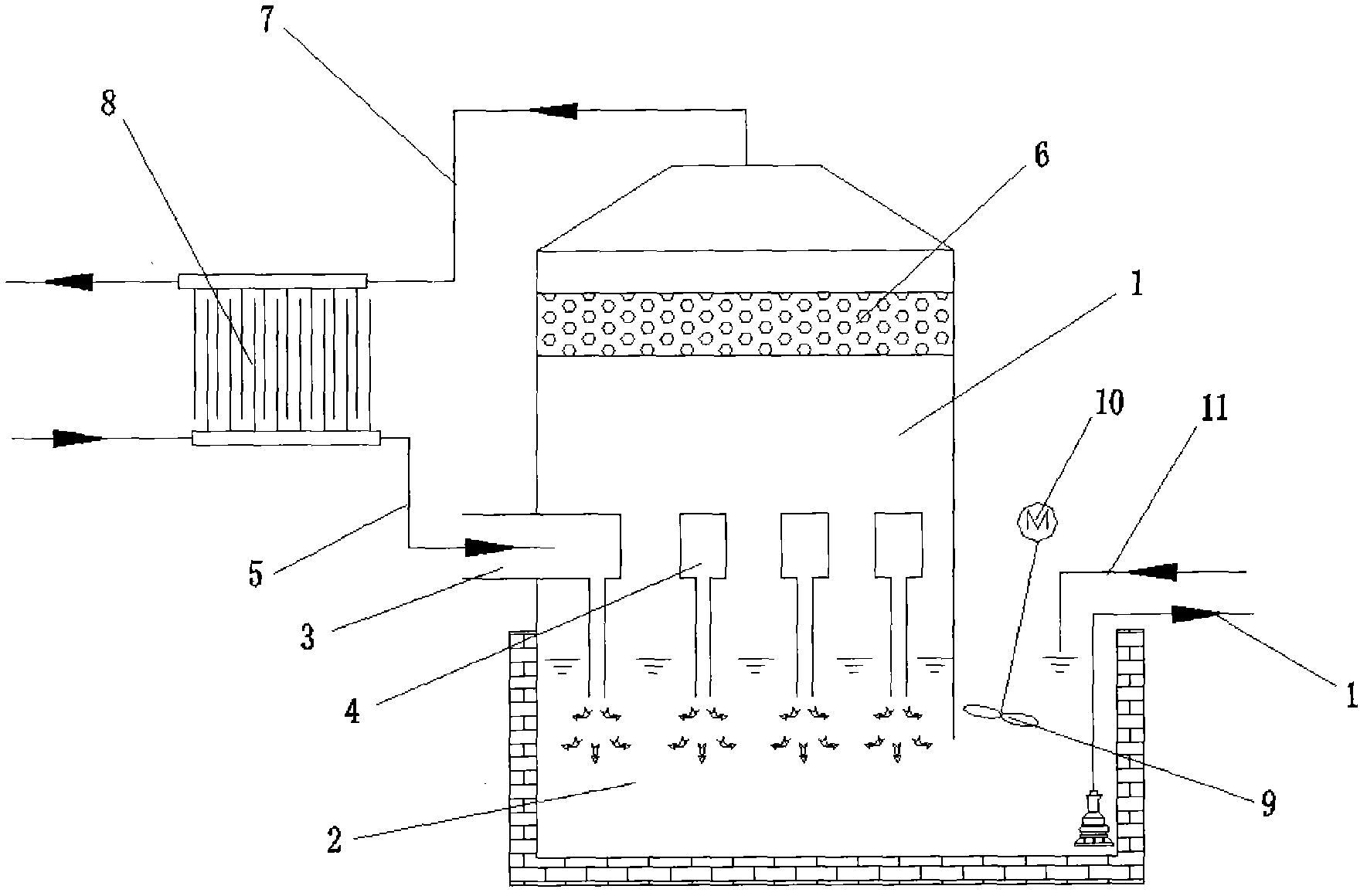

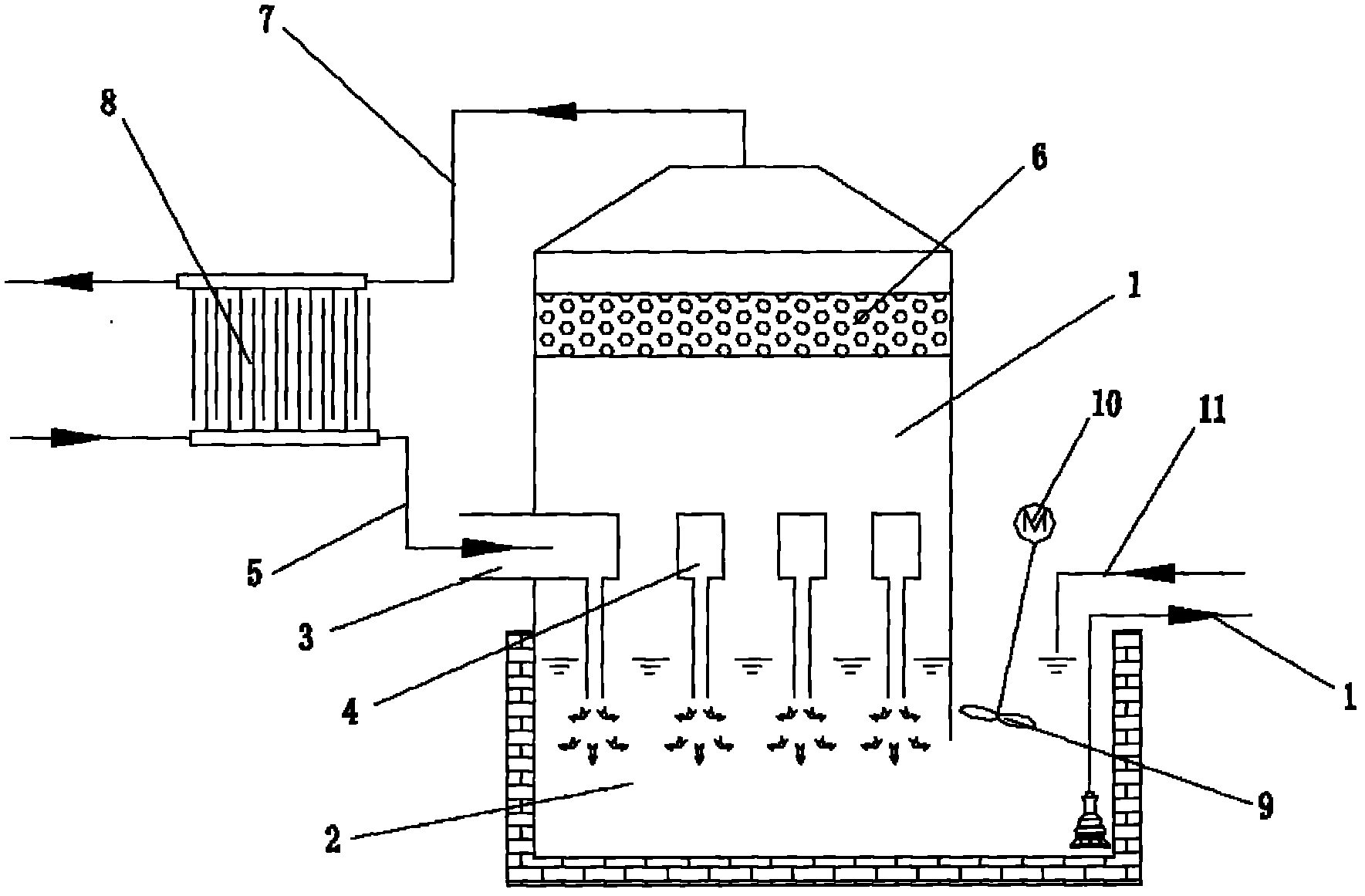

[0026] Such as figure 1 As shown, the present invention provides a blast furnace gas scrubbing and deacidification equipment, comprising a scrubber 1 and an absorption liquid storage tank 2, the middle part of the scrubber is provided with an air inlet pipeline 3 and a plurality of gas dispersion pipelines 4, the inlet The gas pipeline is connected to the original gas pipeline 5 and communicated with multiple gas dispersion pipelines. The bottom of the washing tower is connected to the absorption liquid storage pool, and the bottom of the gas dispersion pipeline extends into the absorption liquid storage pool. The upper part of the washing tower is set There is a packing layer 6, and the purified gas pipeline 7 is connected to the top of the washing tower.

[0027] A heat exchange device 8 is arranged between the raw gas pipeline and the purified gas pipeline.

[0028] A stirring device 9 is arranged in the absorption liquid reservoir, and the st...

Embodiment 2

[0030] Example 2 Blast Furnace Gas Washing and Deacidification Method

[0031] The washing method uses the liquid storage tank, the washing tower and the absorption liquid at the bottom of the washing tower. The absorption liquid is sodium chloride with a weight concentration of 20%. After the raw gas passes through TRT, the raw gas temperature is between 100 and 200°. The gas pipeline and multiple gas dispersing pipelines enter the scrubber, and enter the absorption liquid storage pool at the bottom of the scrubber downward at a high flow rate of not less than 20m / s. The gas is dispersed into fine bubbles and evenly dispersed in the absorption liquid. The absorption process It mainly occurs in two areas: the first is the liquid continuous phase area below the liquid surface of the absorption liquid, which is dispersed into fine bubbles and evenly dispersed in the absorption liquid, and the acid gas molecules are absorbed through the gas-liquid film mass transfer; the second is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com