Preparation method for Lucas reagent

A technology of Lucas reagent and preparation method, which is applied in the field of preparation of Lucas reagent, can solve the problems of low practical success rate, poor reagent sensitivity, complicated and time-consuming preparation, and achieve the effect of preventing hydrogen chloride from escaping and reducing the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

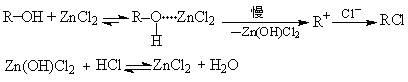

Problems solved by technology

Method used

Image

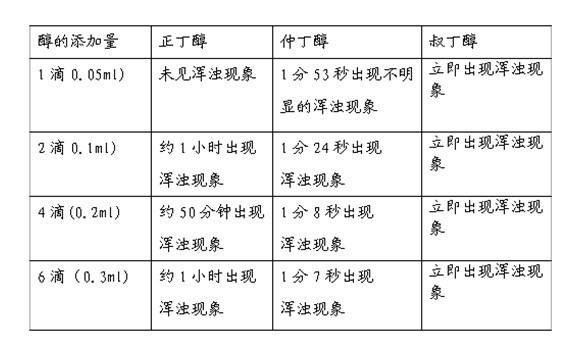

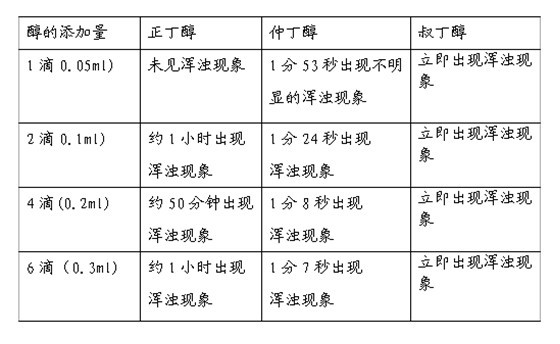

Examples

Embodiment Construction

[0032] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0033] In this example, we take the following steps:

[0034] a. Zinc chloride dehydration: Weigh 340 grams of zinc chloride and place it in an evaporating dish to increase the heat. When the zinc chloride melts and becomes a transparent liquid, remove the evaporating dish containing molten zinc chloride from the heat source and use a glass rod as soon as possible. Stir to disperse zinc chloride into small particles, and crush the particles into powder while hot, and place them in a desiccator to cool;

[0035] b. Dissolve zinc chloride: After the evaporating dish is cooled to room temperature, take it out, pour the mixture into a dry wide-mouth reagent bottle, add 230 ml of cold concentrated hydrochloric acid, quickly seal the bottle mouth with plastic wrap, and place the reagent bottle in an ice-water bath During the process, carefully s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com