Photoresistance removing method

A photoresist removal and photoresist layer technology, applied in photosensitive material processing, electrical components, semiconductor/solid-state device manufacturing, etc. The effect of removing photoresist and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The photoresist removal method of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

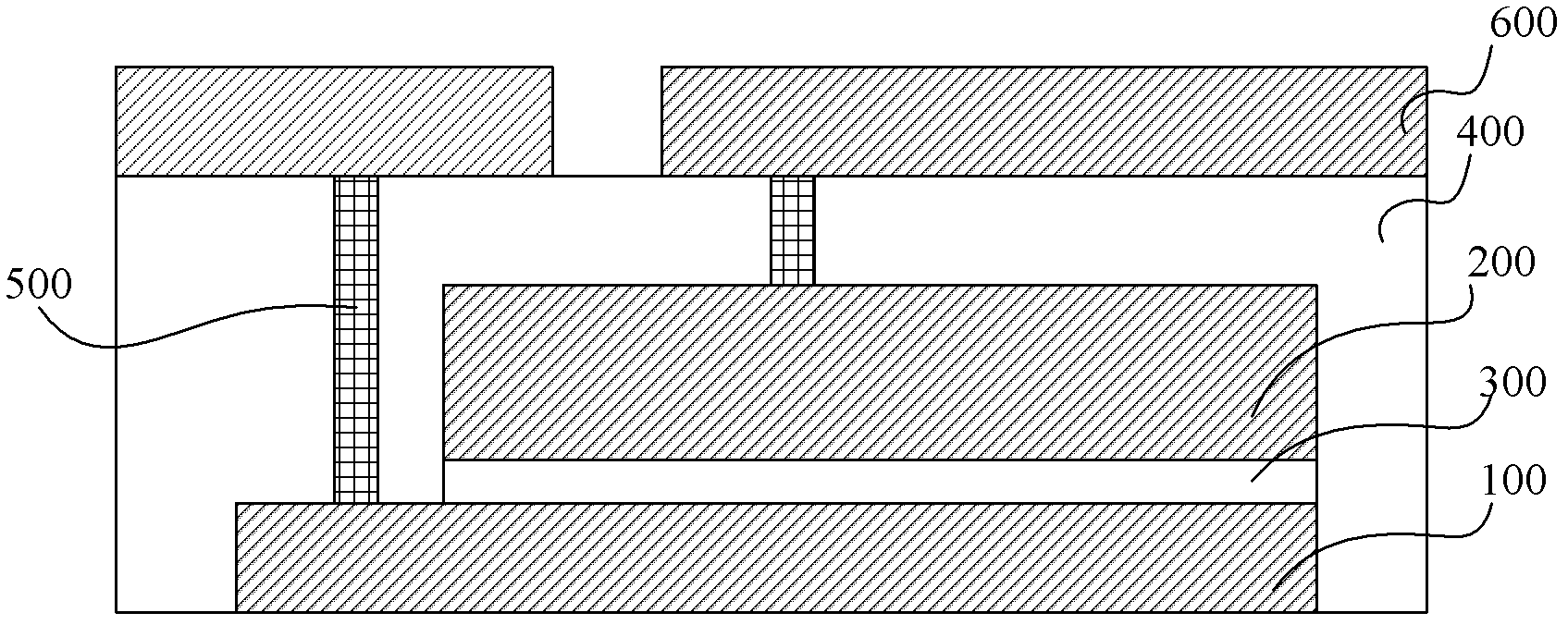

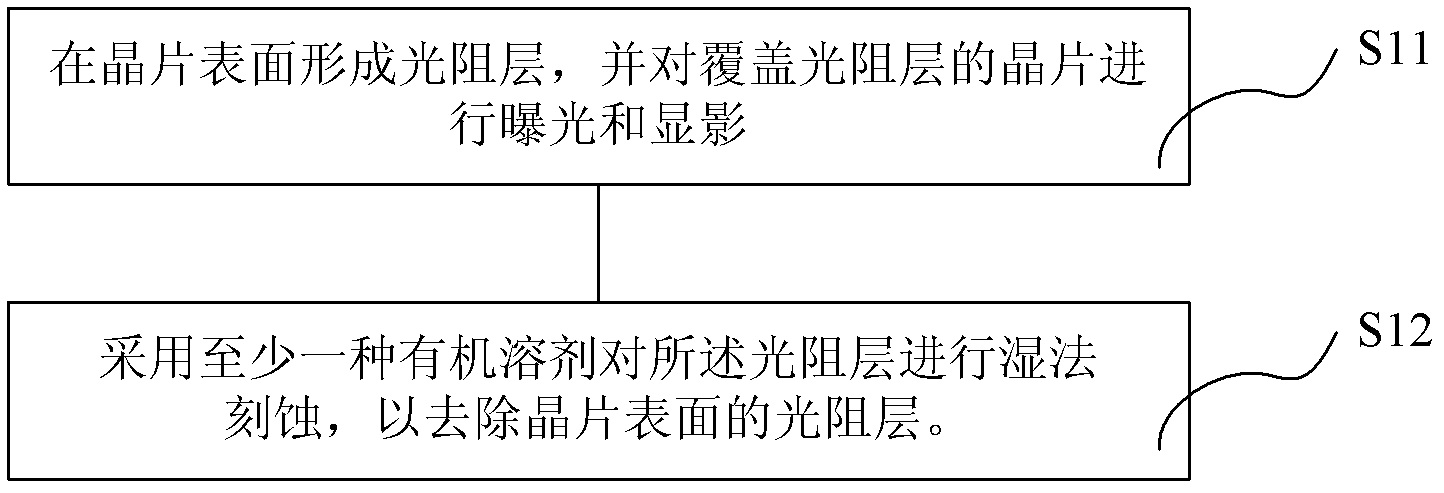

[0017] refer to figure 2 A specific implementation of the photoresist removal method of the present invention is applied to the MIM capacitor manufacturing process, and the specific implementation of the photoresist removal method may include the following steps:

[0018] Step S11, forming a photoresist layer on the surface of the wafer, and exposing and developing the wafer covered with the photoresist layer;

[0019] Step S12 , when the formed photoresist layer needs to be removed, at least one organic solvent is used to perform wet etching on the photoresist layer, so as to remove the photoresist layer on the surface of the wafer.

[0020] Wherein, step S11 may adopt existing process steps and parameters, and its specific implementation process does not affect the idea of the present invention.

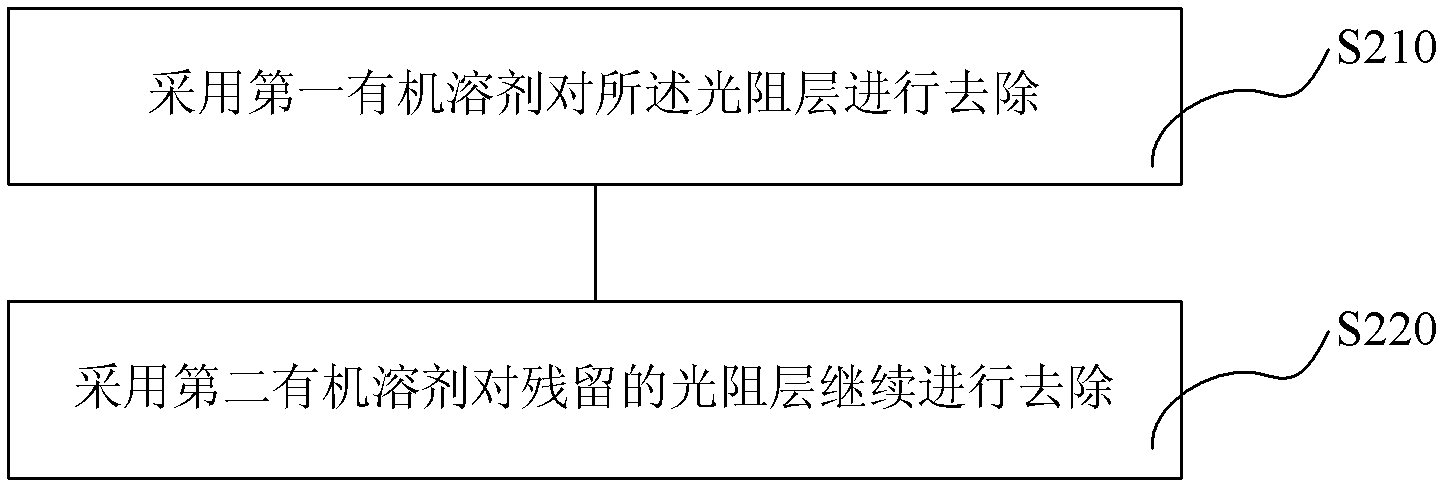

[0021] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com