Electromagnetic shielding sheet with flexural and unbent composite arrangement of carbon fiber endless tow and preparation thereof

An electromagnetic shielding and carbon fiber technology, applied in the field of electromagnetic shielding sheet and its preparation, achieves the effect of increasing electromagnetic shielding efficiency, wide range of uses and less material used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

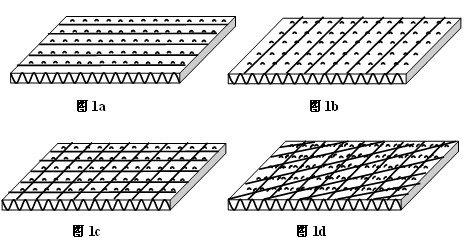

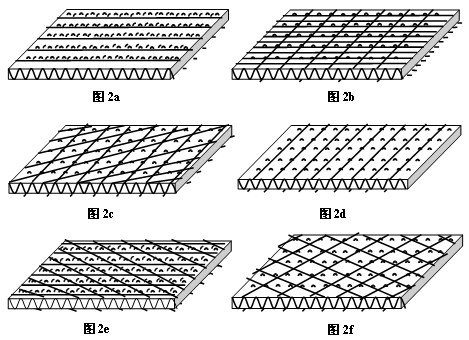

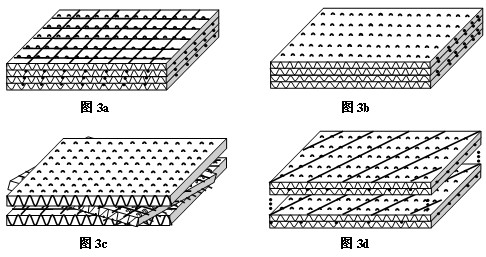

[0038](3) Preparation of composite carbon filament bundles in parallel arrangement: on the buckling arrangement composite sheet, the carbon filament bundles are laid on the composite sheet in parallel or at right angles to the buckling arrangement direction at a certain interval. One side of the sheet, and then pressed into the surface layer of the polymer foam sheet with a pressure cylinder, to obtain a composite sheet with one side parallel to or perpendicular to the buckling arrangement. If it is not arranged in the form of orthogonal squares or oblique diamonds, or not laminated, the straight carbon filament bundles that have been laid in parallel and pressed in are sealed by glue coating or filming, and a single Electromagnetic shielding sheets are arranged parallel to the same direction or parallel to orthogonal buckling on one side of the layer.

[0039] (4) Preparation of composite carbon filament bundles in an orthogonal or diamond-shaped straight arrangement: the car...

Embodiment 1-4

[0045] Embodiment 1-4: single-layer single-sided electromagnetic shielding sheet and its preparation and its electromagnetic shielding performance:

[0046] The raw materials used are commercially available polyacrylonitrile (PAN)-based carbon fiber filament bundle, 200tex / 3000F; PVC foam sheet, silicone rubber.

[0047] Carbon fiber filament bundle buckling arrangement composite sheet preparation: cut the purchased PVC foam sheet into a size of 30cm′30cm, and take a certain pitch of lambda ; Beam spacing; half wavelength or 1 / 4 wavelength, ie d = lambda / 2 or lambda / 4mm. A special steel wire needle is used to shuttle the carbon fiber filament bundles up and down in the PVC foam sheet to form a buckling wave shape until all the carbon fiber filament bundles are passed through, and a composite sheet in parallel buckling arrangement is produced. Or turn the sheet by 90o, and in the same way, the carbon fiber filament bundles are sewn into the foam sheet bundle by bund...

Embodiment 1

[0049] The beam-taking distance is 5mm, and the needle pitch is lambda =4 d = 20 mm of a composite sheet arranged in parallel buckling, on one side of which the carbon fiber filament bundles are stretched and perpendicularly laid, and several carbon fiber filament bundles are cut off, each of which is 35 cm long. In the warp direction of the composite sheet, lay them straight and parallel at intervals of 10 mm and press them in with pressure rollers; then lay carbon fiber filament bundles at the same interval in the weft direction to form a composite sheet with an orthogonal square grid. Cut off the excess carbon fiber filament bundle, and seal the surface with a PVC film with a width greater than 30cm. That is, the single-sided square grid parallel buckling arrangement electromagnetic shielding sheet is obtained, such as figure 1 as shown in c.

[0050] Such as Figure 4 shown, for figure 1 The EMSE (Electro-Magnetic Shielding Efficiency) curve of the electromagnetic sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com