Multilayered structure

A multi-layer structure, outer layer technology, applied in the direction of layered products, synthetic resin layered products, packaged food, etc. synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

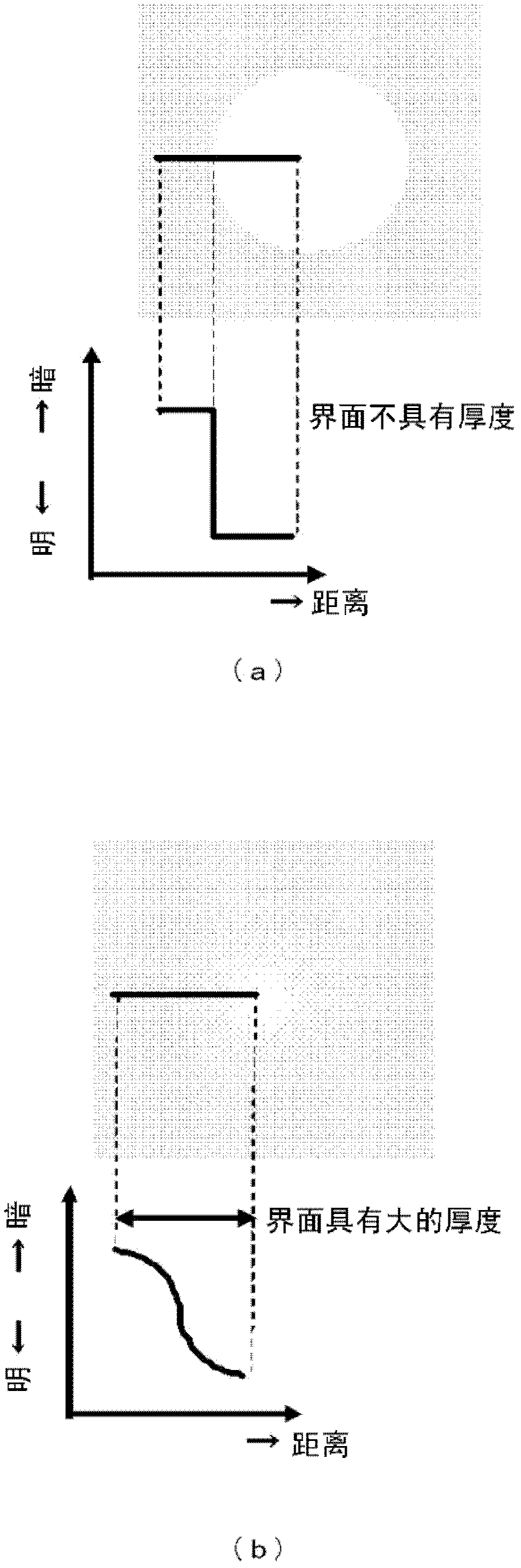

Problems solved by technology

Method used

Image

Examples

Embodiment 1

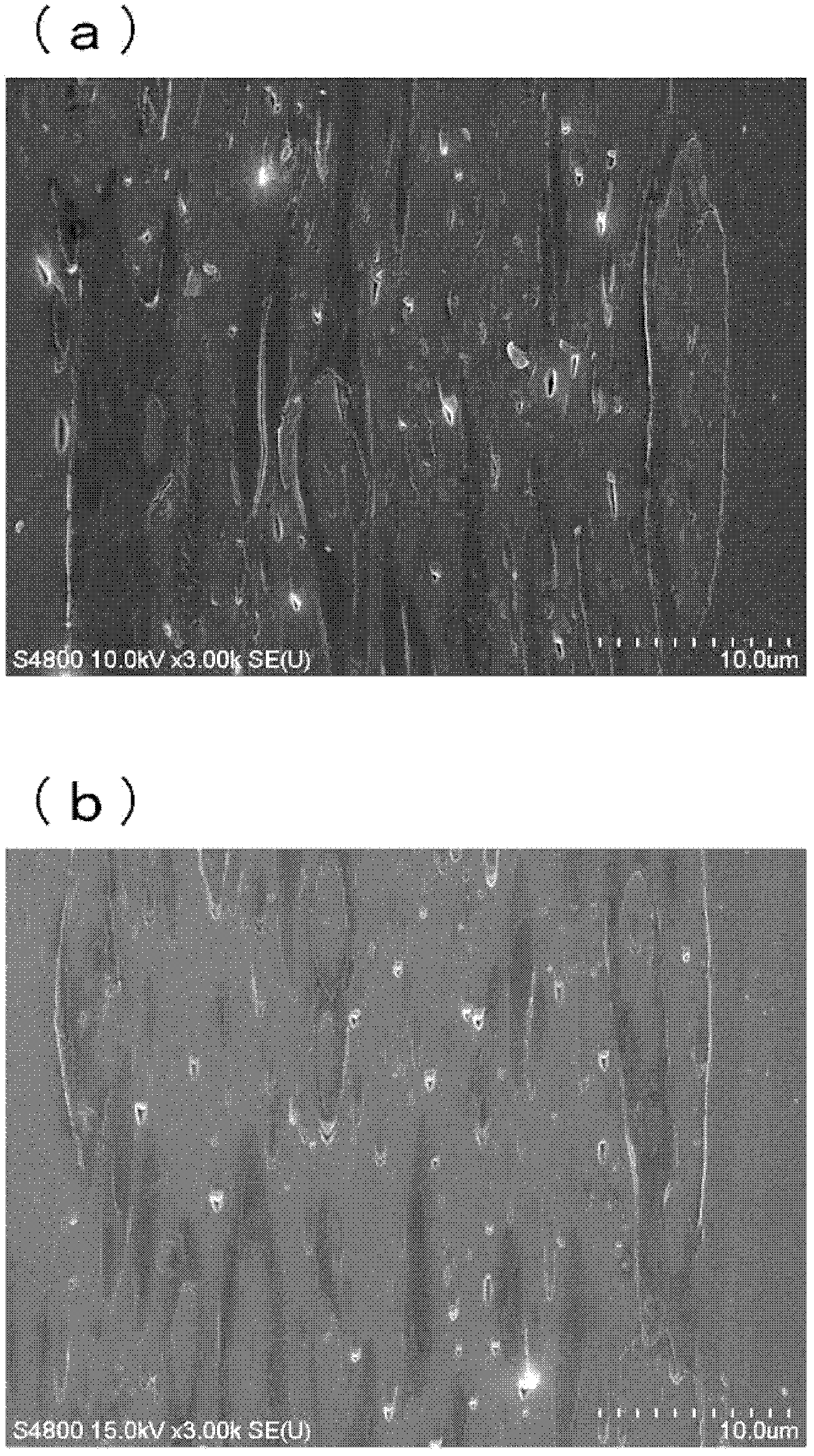

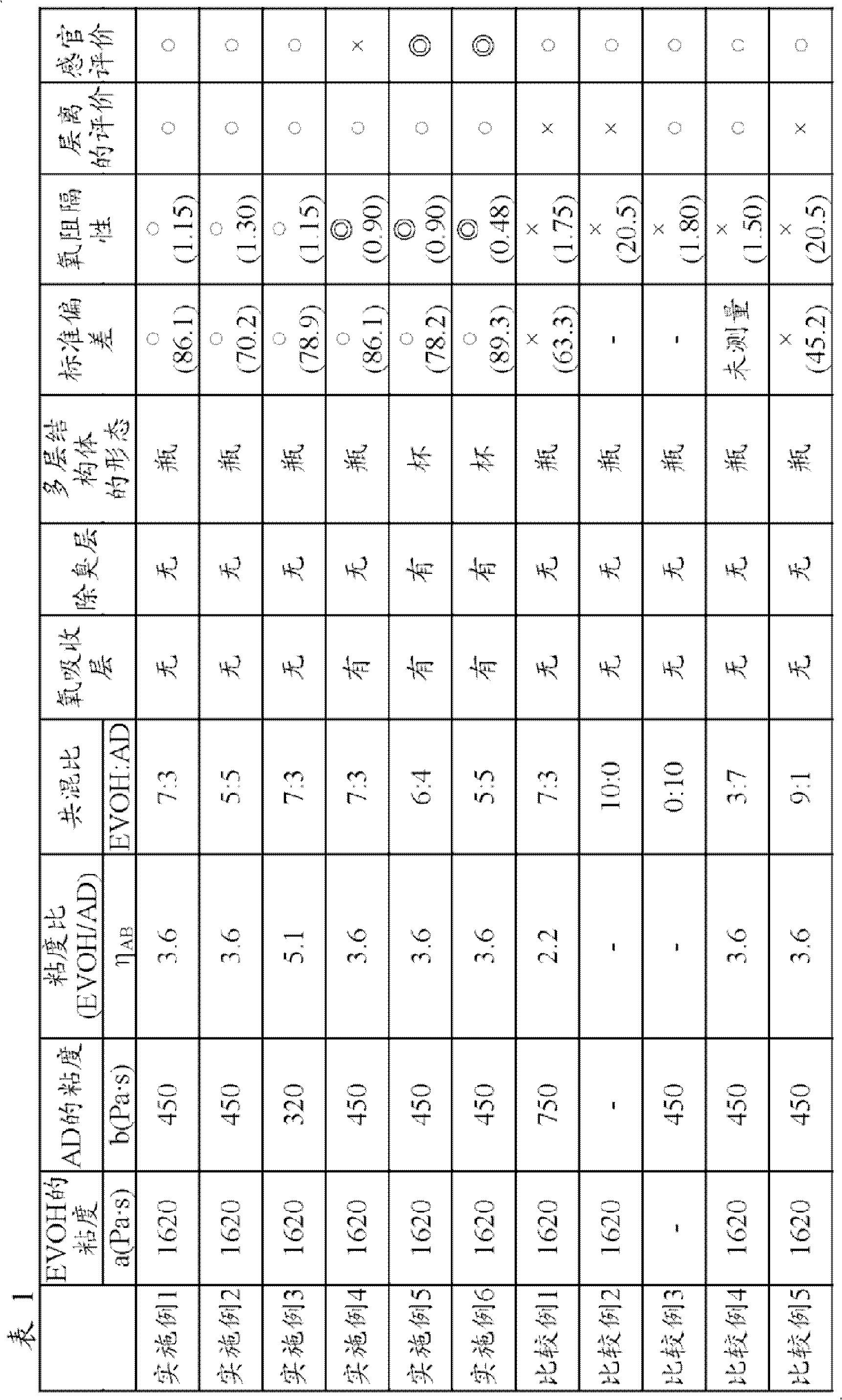

[0161] By using a direct blow molding machine, under conditions of a shell diameter of 15 mm, a core diameter of 13 mm, and a molding temperature of 200° C., a wide-mouthed bottle-shaped multilayer structure (diameter of 44 mm, volume of 125 cc) was produced.

[0162] The layer structure consists of 4 types of 6 layers (outside of the container: polypropylene layer 50 μm / adhesive intermediate layer 25 μm / EVOH layer 35 μm / adhesive intermediate layer 25 μm / recycled material layer 300 μm / polypropylene layer 250 μm: inside the container).

[0163] The resin used was polypropylene (B251VT, manufactured by Prime Polymer Co.) and EVOH (Evar EP-F171B, manufactured by Kuraray Co.), and the adhesive intermediate layer was dry-blended by using EVOH and A blended resin of AD (Adomer QE840, manufactured by Mitsui Kagaku Co.) was formed.

[0164] In addition, the above-mentioned viscosities were measured as a=1620Pa·s, b=450Pa·s and η AB = 3.6.

[0165] Although try to rely on 1 H-NMR me...

Embodiment 2

[0168] A multilayer structure was formed in the same manner as in Example 1 except that the blending ratio of the resin used for the adhesive intermediate layer was changed to 5:5. The standard deviation of the multilayer structure was obtained, its oxygen barrier property and delamination were evaluated, and its sensory evaluation was performed, and the results shown in Table 1 were obtained.

Embodiment 3

[0170] Except using Adomer QE850 manufactured by Mitsui Kagaku Co. instead of using maleic anhydride-modified olefin resin (AD), and by using a blend resin of EVOH and AD (blend ratio 7:3) to the same as Example 1 A multilayer structure was formed in the same manner as in Example 1, except that an adhesive intermediate layer was formed in the same manner as in Example 1. The standard deviation of the multilayer structure was obtained, its oxygen barrier property and delamination were evaluated, and its sensory evaluation was performed, and the results shown in Table 1 were obtained.

[0171] Measure the viscosity of AD as b=320Pa·s, η AB = 5.1.

[0172] Although try to rely on 1 H-NMR measured the acid modification rate of AD, but the peak intensity was so weak that the determination could not be obtained correctly. However, from the peak area, it is estimated that the acid modification rate of AD is not more than 3.6 meq / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com