Surface examination device

A surface inspection device, digital image technology, applied in the direction of measuring device, image data processing, instruments, etc., can solve the problems of time-consuming inspection and inability to know the range and size of polishing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

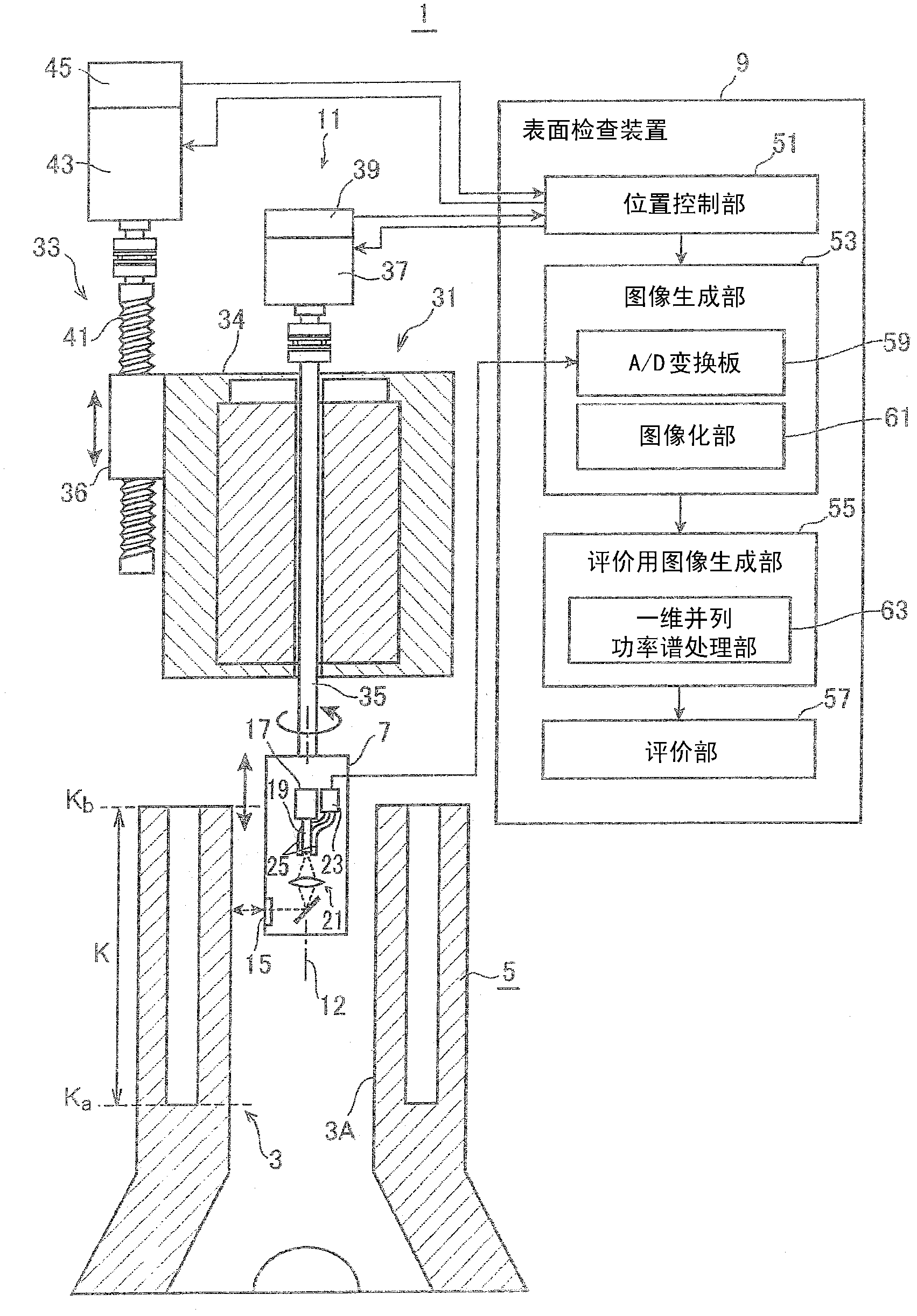

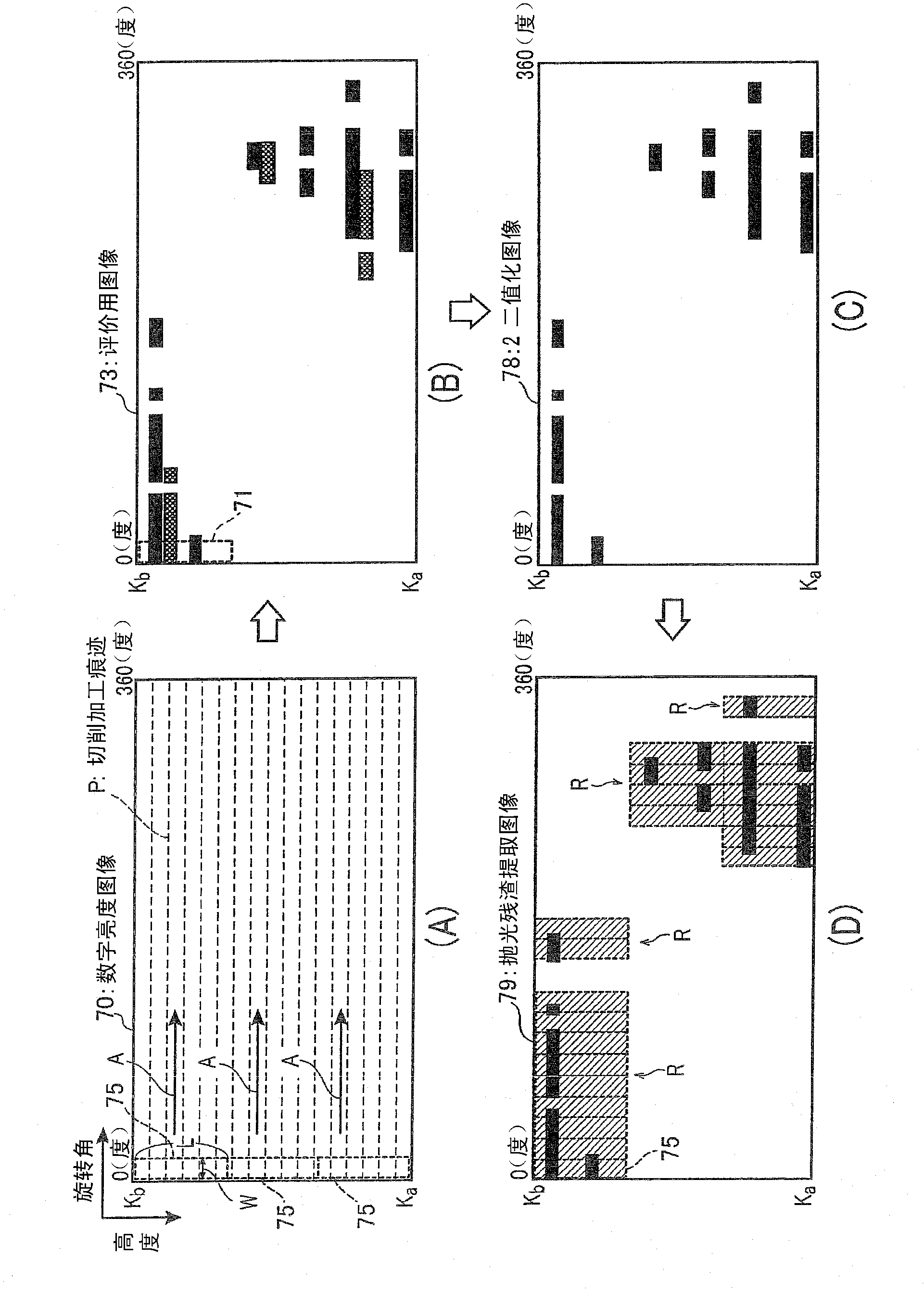

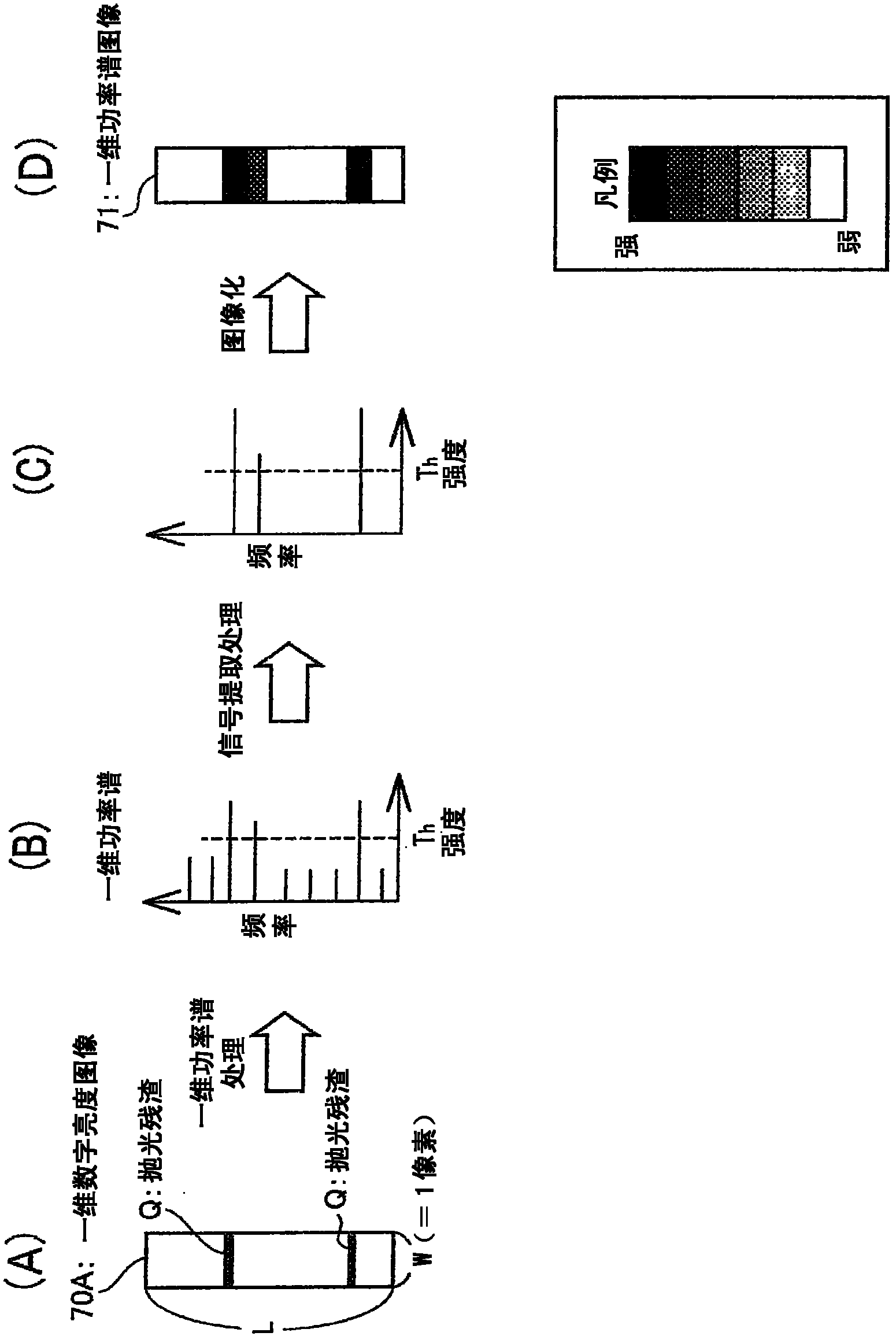

[0073] figure 1 It is a figure which shows the schematic structure of the cylinder bore inner surface inspection system 1 provided with the surface inspection apparatus 9 of this embodiment, and the cylinder block 5 in which the cylinder bore 3 which is an inspection object is formed.

[0074]The cylinder barrel 3 is formed by machining, that is, so-called boring machining, in which a cutting tool is radially protruded from a boring head provided on a rotating shaft, and the boring head is moved forward and backward with respect to the cylinder block 5 as a workpiece while rotating the boring head. form. By this boring process, directional helical cutting traces can be formed on the inner surface 3A of the cylinder barrel 3 . Thereafter, the inner surface 3A of the cylinder bore 3 is honed using a machining head equipped with a honing grindstone in order to obtain surface roughness and surface properties that allow the engine to exhibit desired performance while leaving oil p...

no. 2 Embodiment approach

[0112] In the prior art (Japanese Unexamined Patent Publication No. 2004-132900 ), image processing is performed on a digital image over the entire area of the inner surface of the cylinder bore, which increases the time required for inspection and hinders the improvement of engine productivity. In addition, when foreign matter such as water droplets and dust is adsorbed on the inner surface of the cylinder bore, the foreign matter is reflected on a digital image and erroneously determined as a defect.

[0113] Therefore, in the present embodiment, the surface inspection apparatus 209 which is not affected by foreign matter on the surface and can reduce the time required for inspection by reliably narrowing the range to be subjected to image processing will be described.

[0114] Figure 8 It is a figure which shows the schematic structure of the cylinder bore inner surface inspection system 201 provided with the surface inspection apparatus 209 of 2nd Embodiment of this inv...

no. 3 Embodiment approach

[0141] When cutting the boring of the cylinder block, the forward and backward speed of the boring turning tool with respect to the cylinder block is not limited to be constant at all times. Therefore, since the pitch of the helical machining marks formed on the inner surface of the cylinder barrel changes according to the advancing and retracting speed, the directions of the machining marks are not the same.

[0142] On the other hand, in the prior art (Japanese Unexamined Patent Publication No. 2004-132900 ), the change in the light amount of the reflected light obtained by the scanning of the sensor head depends on the difference between the scanning direction of the sensor head and the direction of the machining traces. offset. That is, when the sensor head is scanned in the direction of the machining mark, the change in the amount of reflected light is small, and the change in the amount of reflected light increases as the angle intersecting the direction of the machining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com