Brown cow milk mildew fermented cheese and preparation method thereof

A fermentation technology of milk mold and lactic acid bacteria, which is applied in the food field, can solve the problems of less original cheese and single product variety, and achieve the effect of reducing spicy and irritating odor, improving flavor and expanding the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

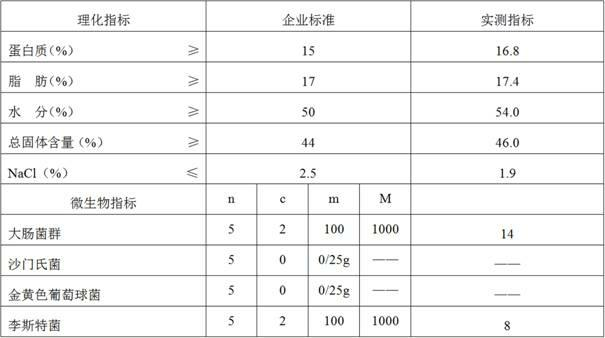

Examples

Embodiment 1

[0027] a) Inspection Inspect the physical and chemical indicators of raw brown milk and fresh milk, the results are: protein 3.2%, fat 3.6%, dry matter 12.5%, acidity 15% o T, the total number of colonies ≤ 1 × 10 5 cfu / mL, butyric acid bacteria and antibiotics were not detected; at the same time, the milk adulteration test was carried out, including alcohol test, boiling test, potassium iodide test and resazurin test;

[0028] b) Standardization Clean the milk that has passed the inspection, and standardize the milk, and adjust the standardized protein and fat ratio (C / F)=0.6;

[0029] c) Sterilization After standardization, sterilize at 72°C for 20 s, and the milk temperature drops to 38°C after sterilization;

[0030] d) Fermentation Add 5g of lactic acid streptococcus to 10kg of sterilized milk Str. lactis , DANISCO), Streptococcus creisinus ( Str. cremoris ,DANISCO), Lactobacillus bulgaricus ( L. bulgaricus , DANISCO) CHOOZIT TM A series of lactic acid bacteria st...

Embodiment 2

[0039] a) Inspection The inspection of raw brown cow milk and fresh milk is as in Example 1;

[0040] b) Standardization Centrifuge the raw brown milk, and standardize the milk, adjust the standardized protein and fat ratio (C / F) = 0.7;

[0041] c) Sterilization After standardization, sterilize at 72°C for 20 s, and the milk temperature drops to 39°C after sterilization;

[0042] d) Fermentation Add 2g of lactic acid streptococcus to 10kg of sterilized milk Str. lactis ,DANISCO), Lactobacillus casei ( L. casci ,DANISCO), Lactobacillus acidophilus ( L. acidophilus ,DANISCO), Lactobacillus bulgaricus ( L. bulgaricus , DANISCO) CHOOZIT TM A series of lactic acid bacteria starters, adding 4g Penicillium Camembert ( Penicillium.candium , DANISCO, CHOOZIT? PC 12) and Geotrichum candidum ( Geotrichum, candidum , DANISCO, CHOOZIT? Geo 17), fully stirred, and fermented for 35 minutes;

[0043] e) Curd The fermented milk is transferred to the curd tank, add 0.75g of calcium c...

Embodiment 3

[0051] a) Inspection The inspection of raw brown cow milk and fresh milk is as in Example 1;

[0052] b) Standardization Centrifuge the raw brown milk and standardize the brown milk, and adjust the standardized ratio of protein and fat (C / F) to 0.8;

[0053] c) Sterilization After standardization, sterilize at 72°C for 15 s, and the milk temperature drops to 38°C after sterilization;

[0054] d) Fermentation Add 6g of lactic acid streptococcus to 10kg of sterilized milk Str. lactis ,DANISCO), Lactobacillus casei ( L. casci , DANISCO), Diacetyl Streptococcus ( Str. diacetilactis ,DANISCO), Lactobacillus bulgaricus ( L. bulgaricus , DANISCO), Leuconostoc citricophilus ( Leu. citrovorum , DANISCO) CHOOZIT TM A series of lactic acid bacteria starters, adding 5g Penicillium Camembert ( Penicillium.candium , DANISCO, CHOOZIT? PC 12) and Geotrichum candidum ( Geotrichum candidum , DANISCO, CHOOZIT? Geo 17), fully stirred, and fermented for 45 minutes;

[0055] e) Curd ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total number of colonies | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com