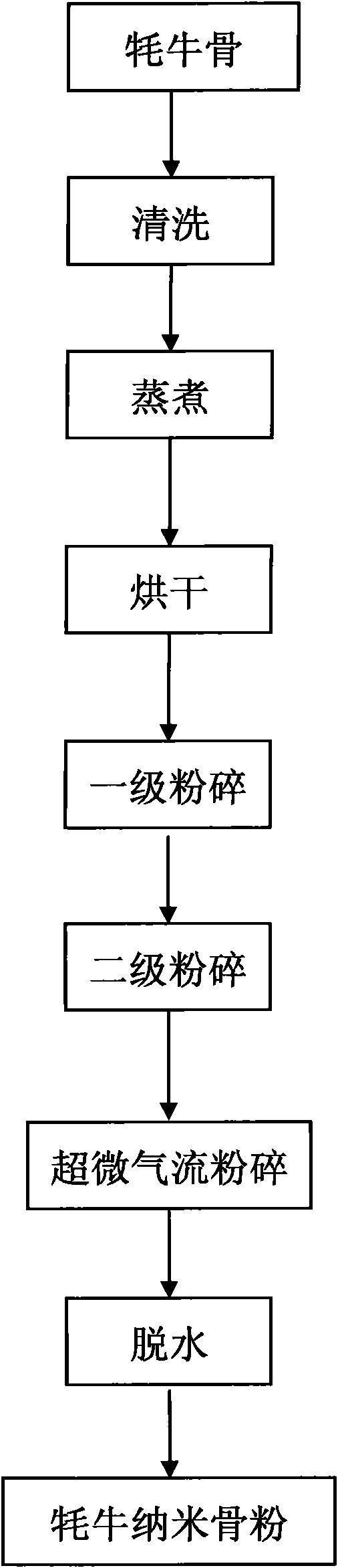

Processing method of nano yak bone powder

A processing method, the technology of yak bone powder, which is applied in the field of food processing, can solve the problems of difficult processing and utilization, and achieve the effect of easy operation, good taste and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Select 5kg of Tibetan yak bones, wash to remove sundries, fur, blood, etc. The cleaned yak bone is subjected to high-pressure cooking, the cooking temperature is 150°C, the pressure is 0.6Mpa, and the time is 1.5h. Then dry at 60°C for 10 minutes. The above-mentioned yak bone was crushed for 15 minutes by using a mechanical pulverizer to obtain yak bone powder with a particle size of 200 μm to 500 μm. Grinding with GNM series bone mud mill for 15 minutes at a temperature of 65°C to 75°C, the particle size of yak bone powder is below 100 μm. At room temperature, the above-mentioned yak bone powder is pulverized by airflow, the air pressure is 0.6Mpa, and the gas-solid ratio is 2:1. Drying with hot air at 70 DEG C to 80 DEG C, the obtained yak nano bone powder has a particle size of 100 nm to 300 nm and a water content of 1.53%.

Embodiment 2

[0024] Select 20kg of Tibetan yak bones, wash to remove sundries, fur, blood, etc. The cleaned yak bone is subjected to high-pressure cooking, the cooking temperature is 160°C, the pressure is 0.6Mpa, and the cooking time is 1.5h. Then dry at 60°C for 20 minutes. The above-mentioned yak bone is crushed for 20 minutes by using a mechanical pulverizer to obtain yak bone powder with a particle size of 200 μm to 500 μm. Grinding with GNM series bone mud mill for 20 minutes at a temperature of 65-75°C, the particle size of yak bone powder is below 100 μm. At room temperature, the above-mentioned yak bone powder is pulverized by airflow, the air pressure is 0.7Mpa, and the gas-solid ratio is 2:1.5. Drying with hot air at 70 DEG C to 80 DEG C, the obtained yak nano bone meal has a particle size of 100 nm to 300 nm and a water content of 1.66%.

Embodiment 3

[0026] Select 100kg of fresh Tibetan yak bones, wash and remove sundries, fur, blood, etc. The cleaned yak bone is subjected to high-pressure cooking, the cooking temperature is 180°C, the pressure is 0.6Mpa, and the time is 1.5h. Then dry at 65°C for 20 minutes. The above-mentioned yak bone was pulverized for 30 minutes by using a mechanical pulverizer to obtain yak bone powder with a particle size of 200 μm˜500 μm. Grinding with GNM series bone mud mill for 25min at a temperature of 65°C to 75°C, the particle size of yak bone powder is below 100μm. At room temperature, the above-mentioned yak bone powder is pulverized by airflow, the air pressure is 0.7Mpa, and the gas-solid ratio is 3:1. Drying with hot air at 70 DEG C to 80 DEG C, the obtained yak nano bone meal has a particle size of 100 nm to 300 nm and a water content of 1.75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com