Synthesis method of polymethoxy methylal

A technology of polymethoxymethylacetal and a synthesis method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of difficult catalyst separation, high energy consumption for processing, process corrosion and the like, and achieve product Good distribution, simple reaction process, and the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

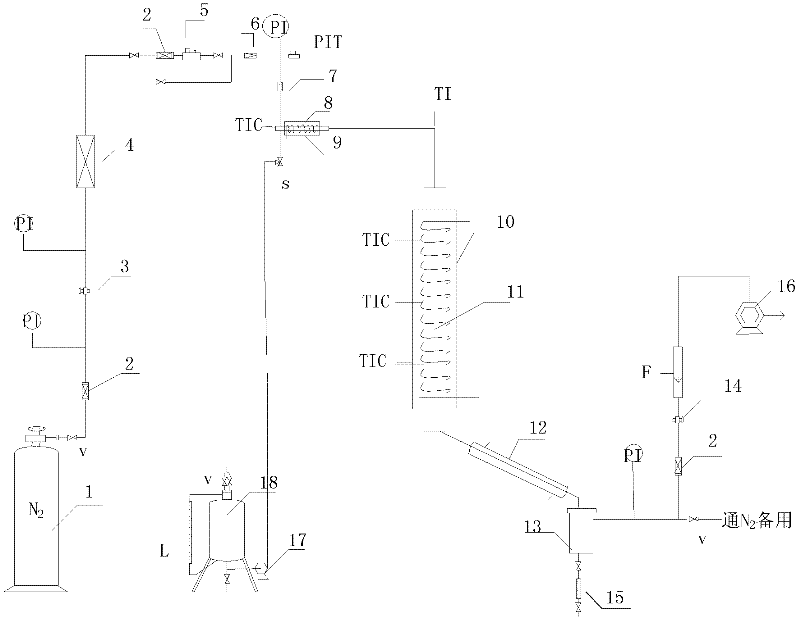

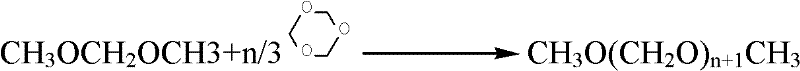

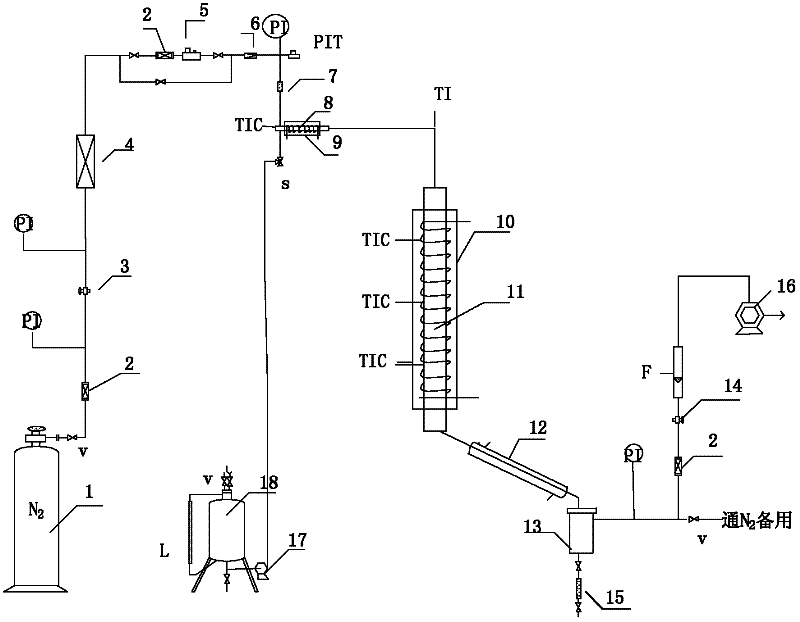

Method used

Image

Examples

Embodiment 1

[0029] In the fixed-bed reactor, the acidic styrene-based cation exchange resin catalyst is packed, and the N 2 Cylinder 1 is pressurized to 1.5MPa, and the raw material with a molar ratio of methylal and paraformaldehyde of 2 is added to the raw material tank, passed through a high-pressure cross-flow pump, and entered into the bed through a preheater, and the temperature of the reaction furnace is set to 100°C. Airspeed is 0.5h -1 After the reaction, samples were taken, and analyzed by gas chromatography, the conversion rate of paraformaldehyde was 93.1%, and the relative content was 23.6% for trimers and 16.1% for tetramers.

Embodiment 2

[0031] Same example 1, the catalyst is an acidic styrene-based cation exchange resin, and the space velocity is 0.5h -1 , the molar ratio of methylal to paraformaldehyde is 2, the reaction pressure is 2MPa, and the reaction temperature is 100°C. Sampling and analysis by gas chromatography shows that the conversion rate of paraformaldehyde is 94.8%. The relative content is 29.7% for trimers and 21.2% for tetrapolymers. %.

Embodiment 3

[0033] Same example 1, the catalyst is an acidic styrene-based cation exchange resin, and the space velocity is 0.5h -1 , the molar ratio of methylal to paraformaldehyde is 2, the reaction pressure is 4MPa, and the reaction temperature is 100°C. Sampling and analysis by gas chromatography shows that the conversion rate of paraformaldehyde is 95.9%, and the relative content is 30.0% for trimers and 21.9% for tetrapolymers. %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com