Method for extracting and separating rosmarinic acid and ursolic acid from rosemary

A technology of rosmarinic acid and rosemary, applied in the separation/purification of carboxylic acid esters, steroids, organic chemistry, etc., can solve the problems of low cost, low yield, large active ingredient content, etc., and achieve Low production cost, simple operation, and improved economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

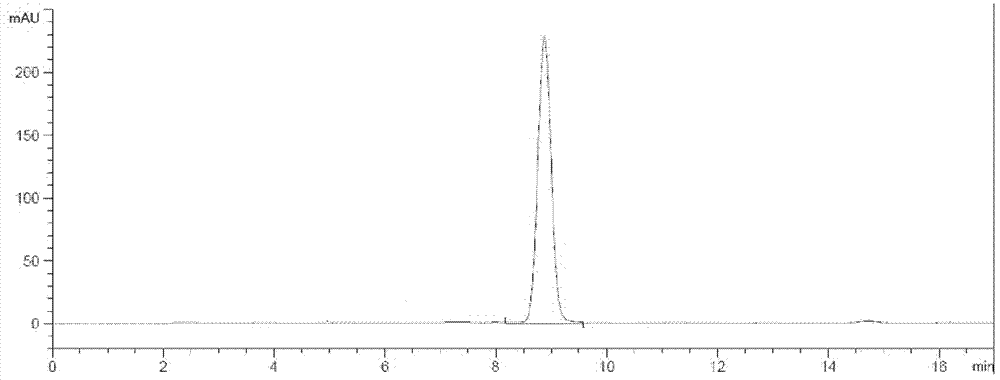

[0048] Weigh 100Kg of rosemary, crush it, place it in 300L (V / V) of 60% ethanol at 40°C for 4 hours in vacuum, filter it once with a ceramic membrane; Filter the membrane again, and combine the two filtrates; add an appropriate amount of antioxidant 150g to the filtrate and concentrate in vacuum at 50°C until 12kg of dry matter is obtained; dissolve the obtained dry matter with 60L of 30% ethanol, filter it once with a ceramic membrane, and put the filtrate on the LSA-10 macroporous resin column, after adsorption, remove impurities with 60L petroleum ether and 60L ethyl acetate respectively, desorb with 60L pH3.5, 45% ethanol solution, collect eluate A; filter residue 8kg 16L of acetone was dissolved, filtered, and the filtrate was applied to an LSA-10 macroporous resin column. After adsorption, impurities were removed with petroleum ether and ethyl acetate, and 40L of pH6.5, 60% methanol solution was used for desorption and collected. Eluate B; Concentrate eluate A and eluate...

Embodiment 2

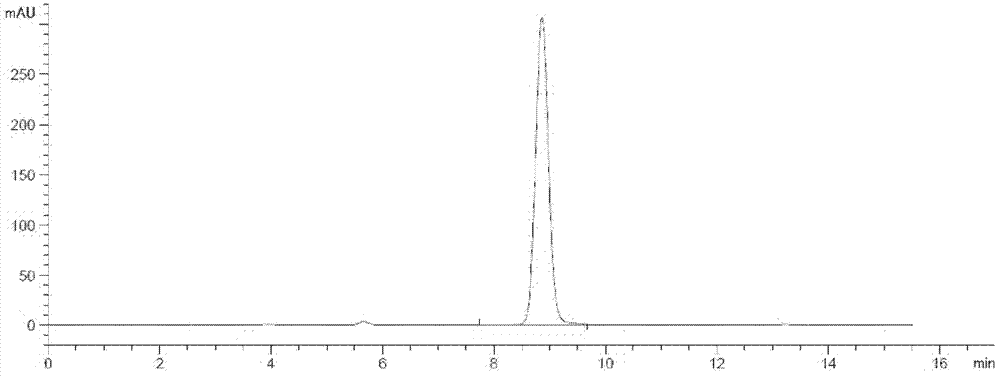

[0050] Weigh 200Kg of rosemary, crush it, place it in 600L (V / V) of 60% ethanol at 40°C for 4h in vacuum, filter it once with a ceramic membrane; Filter the membrane again and combine the two filtrates; add an appropriate amount of antioxidant 250g to the filtrate and concentrate in vacuum at 50°C until 25kg of dry matter is obtained; dissolve the obtained dry matter with 125L of 30% ethanol, add activated carbon for decolorization for 15min, and then ceramic Membrane filtration once, the filtrate was put on LSA-10 macroporous resin column, after adsorption, impurities were removed with 120L petroleum ether and 120L ethyl acetate respectively, desorbed with 120L pH3.5, 45% ethanol solution, collected and eluted Matter A; filter residue 20kg dissolves with 40L acetone, filters, and the LSA-10 macroporous resin column on the filtrate, after adsorption, carries out impurity removal with sherwood oil, ethyl acetate respectively, uses the pH6.5 of 80L, 60% methyl alcohol The soluti...

Embodiment 3

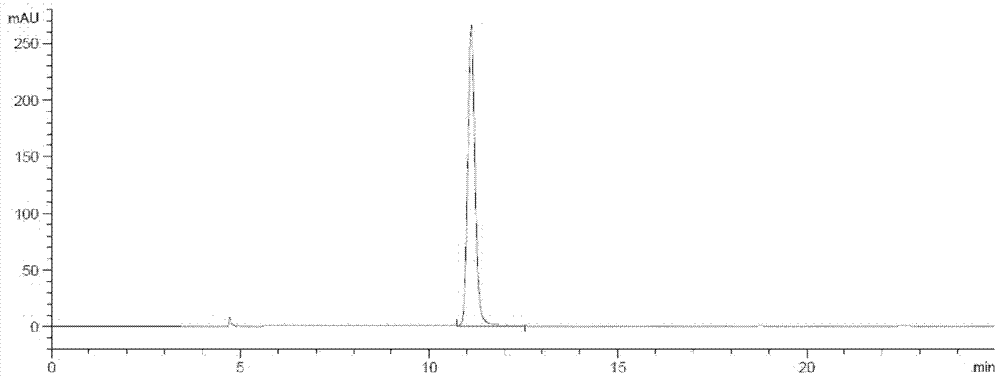

[0052]Weigh 500Kg of rosemary, pulverize, place 1500L (V / V) in 60% ethanol at 40°C for vacuum insulation for 4h, and filter once with ceramic membrane; filter residue is added to 1000L of 60% ethanol, 40°C for vacuum insulation for 4h, Filtrate the ceramic membrane again, and combine the two filtrates; add an appropriate amount of antioxidant 500g to the filtrate and concentrate in vacuum at 50°C until 70kg of dry matter is obtained; dissolve the obtained dry matter with 350L of 30% ethanol, add activated carbon for decolorization for 15min Filter once with a ceramic membrane, put the filtrate on an LSA-10 macroporous resin column, and after adsorption, remove impurities with 300L petroleum ether and 300L ethyl acetate, desorb with 300L pH3.5, 45% ethanol solution, and collect the washed De-material A; filter residue 45kg was dissolved with 90L of acetone, filtered, and the filtrate was put on LSA-10 macroporous resin column, after adsorption, impurities were removed with petro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com