Polystyrene nanoparticle adsorbed on mica sheet surface and preparation method thereof

The technology of polystyrene nanometer and polystyrene solution is applied in the field of preparation of polystyrene nanoparticle, which can solve the problems of complex process and achieve the effects of simple operation process, good industrial application prospect and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

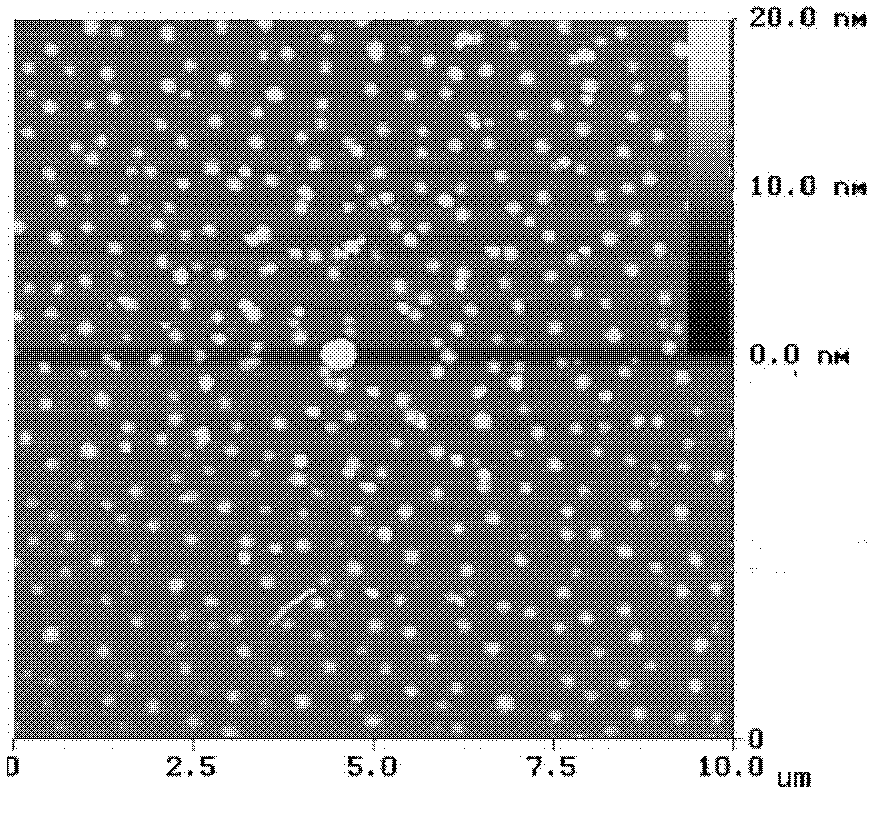

[0023] First, high-purity toluene solvent was obtained by secondary distillation, and a certain amount of polystyrene with a molecular weight of 570,000 g / mol and a distribution width index of 1.025 was weighed and dissolved in toluene to form a concentration of 0.01% g / mol. ml of polystyrene solution and let it stand for about a week. Take a mica sheet with a thickness of 0.25nm, and then use scotch tape to remove the mica sheet and use scotch tape to remove the surface layer of the mica sheet matrix to obtain a flat and smooth surface. Drop 1 drop of the solution on the mica sheet, and then spin-coat the polystyrene solution on the surface of the clean mica sheet substrate by spin coating. The rotation speed and time of the first stage of spin coating are respectively 300 rpm and 10 seconds; The second stage is 2000 rpm, 60 seconds. Carefully take out the coated mica sheet with tweezers (clamp the edge), put it face up into a washed and dried petri dish, seal and dry for 24...

Embodiment 2

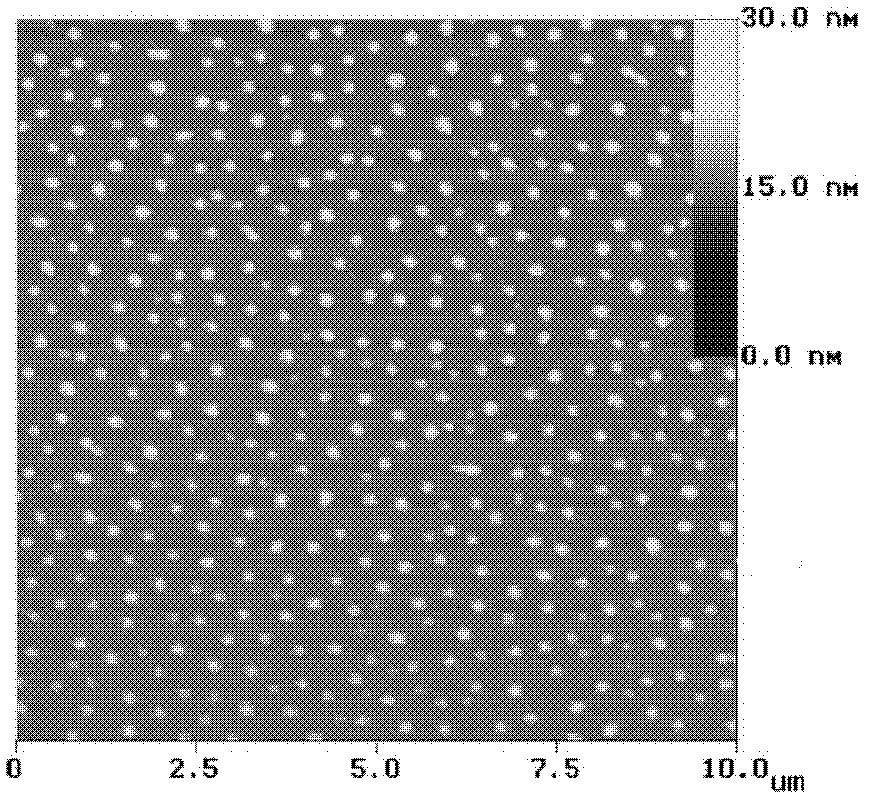

[0025] First, adopt the method of secondary distillation to obtain high-purity dichloromethane solvent, weigh a certain amount of molecular weight and be 570000g / mol, polystyrene with a distribution width index of 1.025, dissolve it in dichloromethane, and form a concentration of 0.005% g / ml polystyrene solution, let stand for about a week. Take a mica sheet with a thickness of 0.35nm, and then use scotch tape to remove the mica sheet and use scotch tape to remove the surface layer of the mica sheet matrix to obtain a flat and smooth surface. Drop 2 drops of solution on the mica sheet, and then spin-coat the polystyrene solution on the surface of the clean mica sheet substrate by spin coating. The rotational speed and time of the first stage of spin coating are respectively 350 rpm and 12 seconds; The second stage is 2500 rpm, 80 seconds. Carefully take out the coated mica sheet with tweezers (clamp the edge), put it face up into a washed and dried petri dish, seal and dry fo...

Embodiment 3

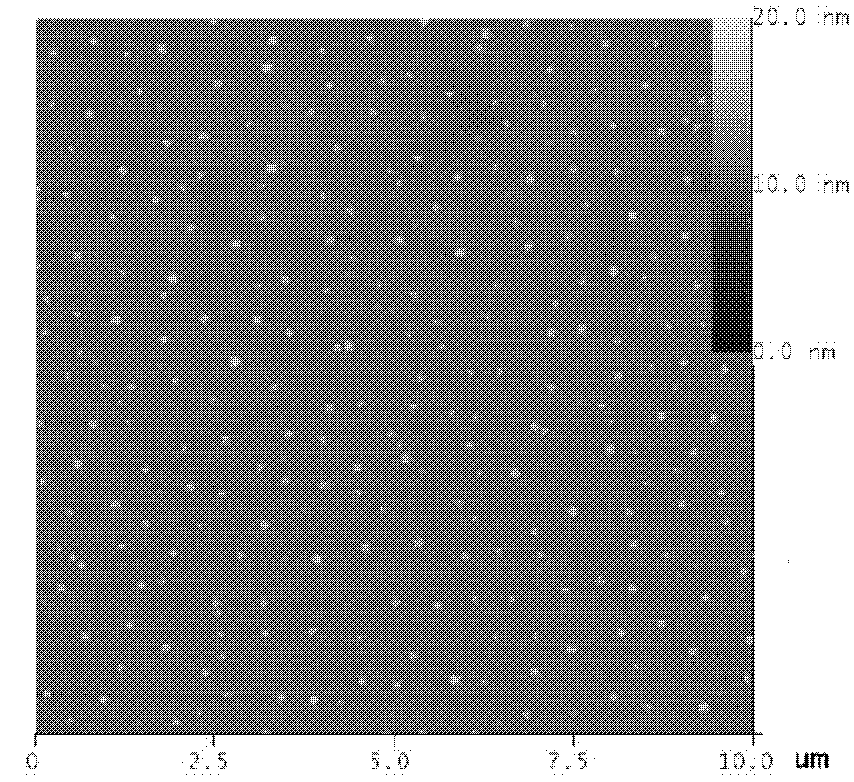

[0027] First, adopt the method of secondary distillation to obtain high-purity trichloromethane solvent, take a certain amount of molecular weight and be 570000g / mol, the polystyrene that the distribution width index is 1.025, it is dissolved in the trichloromethane, the formation concentration is 0.0005% g / ml polystyrene solution, let stand for about a week. Take a mica sheet with a thickness of 0.5nm, and then use scotch tape to remove the mica sheet and use scotch tape to remove the surface layer of the mica sheet matrix to obtain a flat and smooth surface. Drop 1 drop of solution on the mica sheet, and then spin-coat the polystyrene solution on the surface of the clean mica sheet substrate by spin coating. The rotation speed and time of the first stage of spin coating are respectively 400 rpm and 14 seconds; The second stage is 3000 rpm, 90 seconds. Carefully take out the coated mica sheet with tweezers (clamp the edge), put it face up into a washed and dried petri dish, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com