Control method for biomass gasification equipment

A control method and biomass technology, applied in fixed bed gasification and other directions, can solve the problems of uncontrollable gas composition, high possibility of operation errors, long smoke exhaust time, etc., and achieve stable and controllable gas composition and possibility of operation errors. Small, the effect of improving the efficiency of gasification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

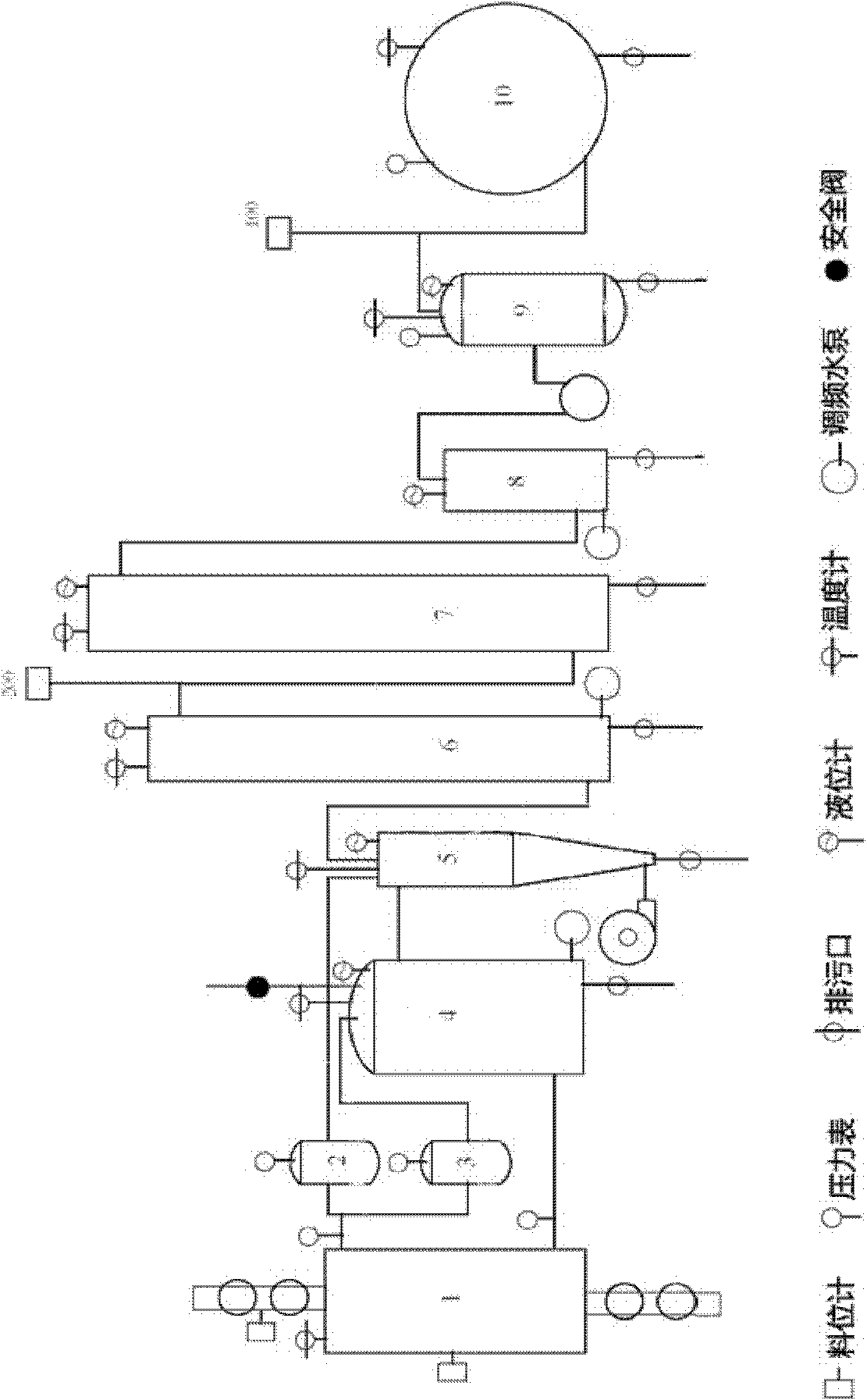

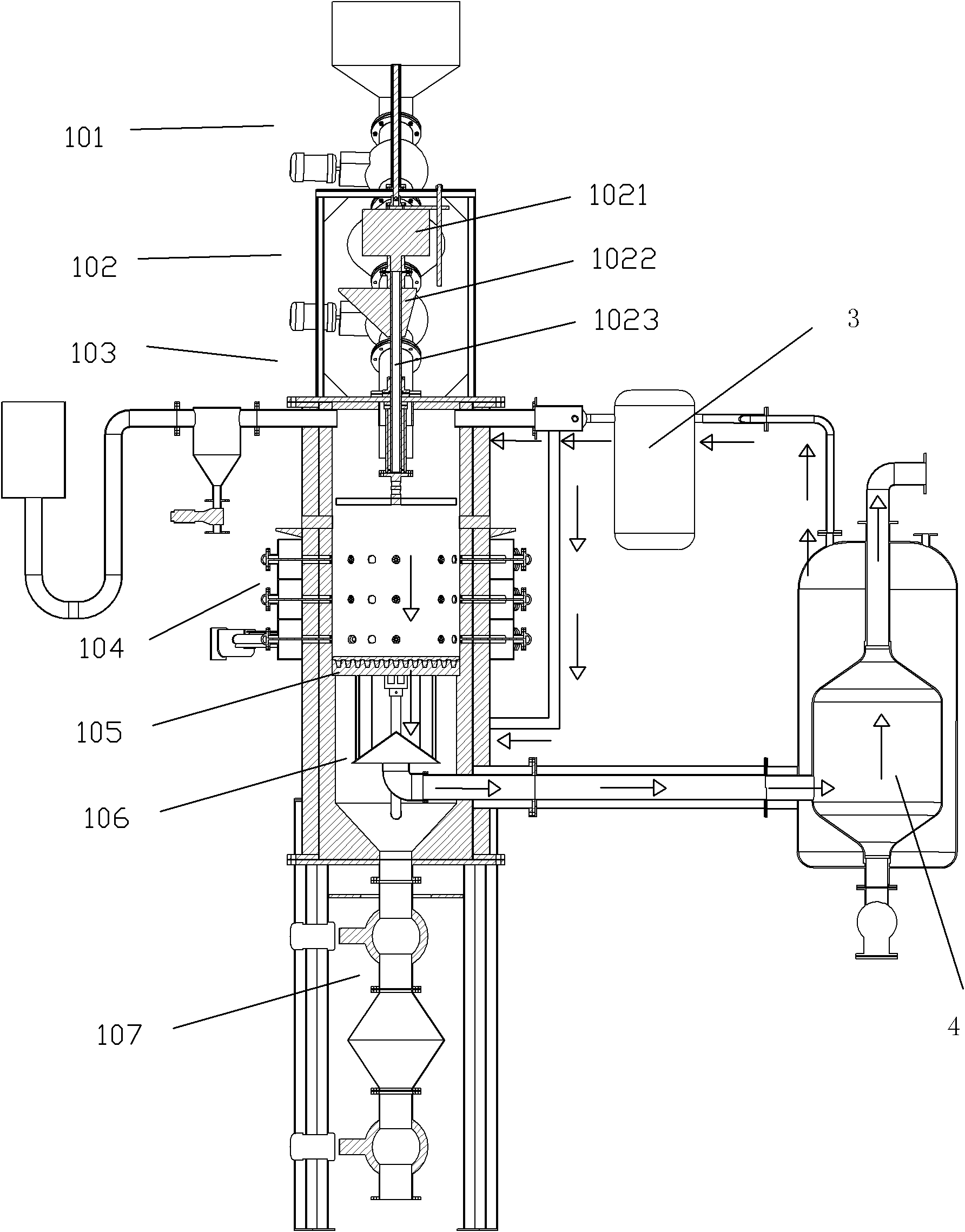

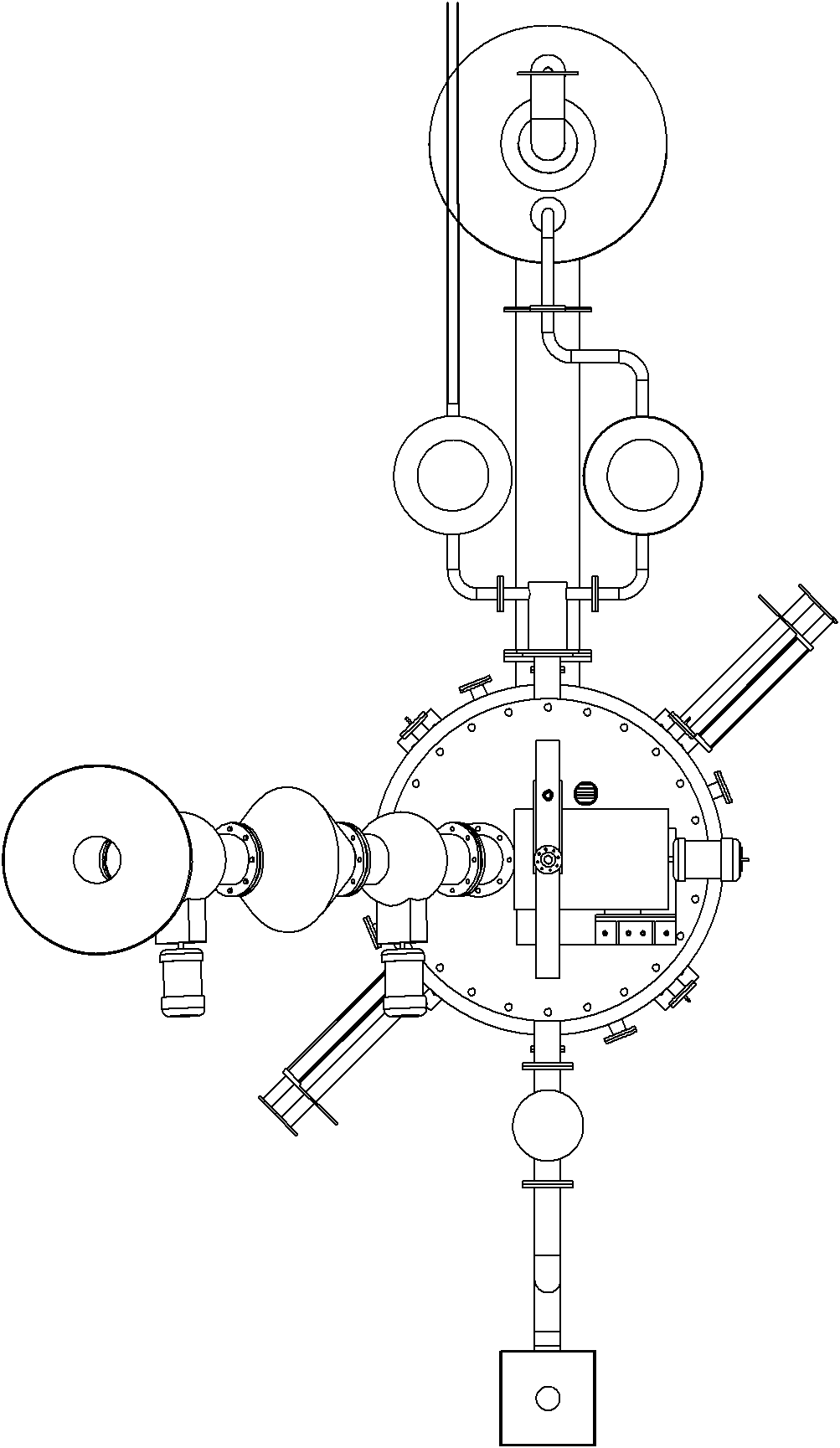

[0126] The applicant proposes a new type of biomass gasification equipment, which includes a gasification reaction chamber connected in sequence by a gas pipeline, an air buffer tank, a steam buffer tank, a steam heat exchanger, an internal and external double cyclone heat exchange dust collector, an inertial separator, Cooling tower, electric tar collector, hydrogen sulfide removal sprayer, gas-water separator and gas storage tank; the above-mentioned devices are respectively matched with Siemens S7-300 (PLC) program control system to detect the temperature, pressure and ignition of each area in the generation room device. The thermocouple is equipped with relevant flowmeters, thermometers, and gas analyzers to read the temperatures and contents of various gases in all generated gases, analyze the starting ignition device, and feed back the readings to the control panel in time to exchange data with the customer's generator equipment. feedback. When the system is in a critic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com