Coated soybean cheese and making method thereof

A production method and smear-type technology, which is applied in the field of smear-type soybean cheese and its production, can solve the problems of soybean protein gel such as poor smearability and melting in the mouth, unsatisfactory quality and flavor characteristics, etc., so as to relieve menopausal conditions and relieve demand The effect of stress and prevention of arteriosclerosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

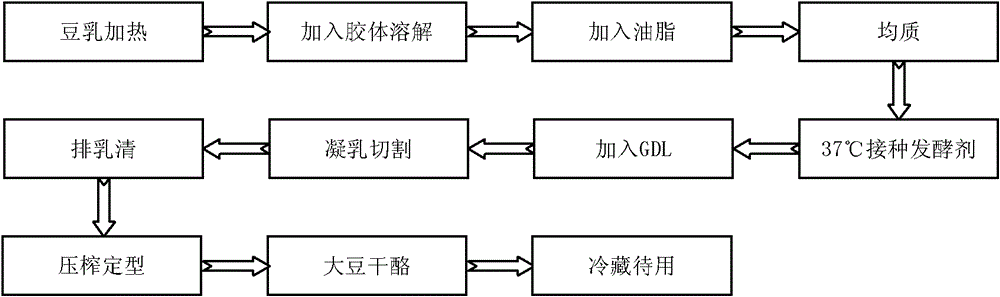

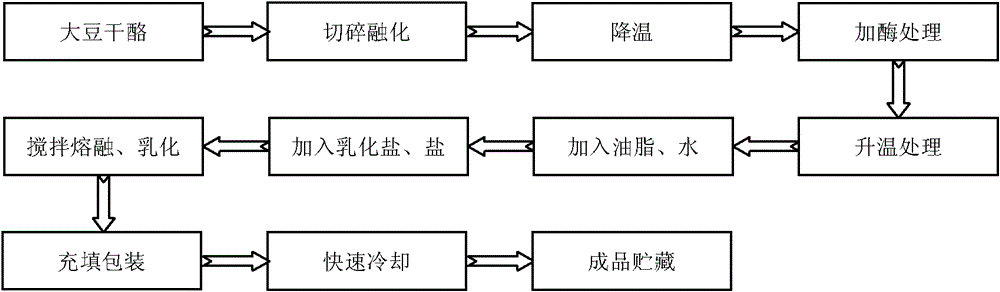

[0030] Example 1 , the preparation of soybean cheese

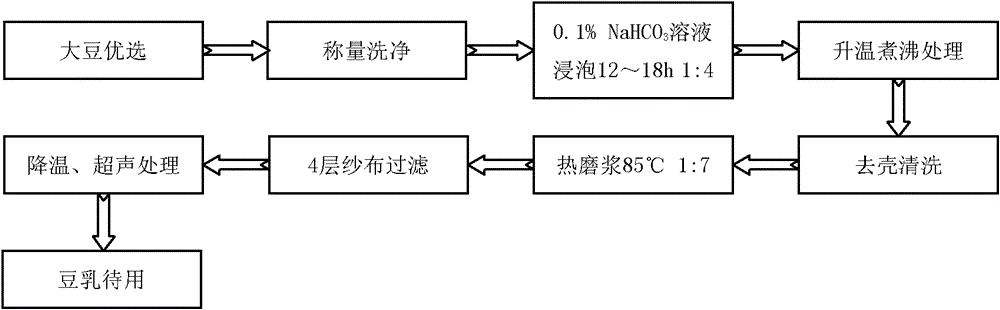

[0031] 1.1. Preparation of soybean milk

[0032] In this example, the preparation of soybean milk refers to the conventional method, the main difference is that baking soda is added to remove the beany smell and ultrasonic treatment is used in the process, the details are as follows:

[0033] like figure 1 As shown, take northeast soybeans, wash them and soak them in water at room temperature for 12-18 hours. In order to reduce the beany smell, baking soda is added at the same time, and the amount added is 0.1-0.3% (w / v) of the total weight of the mixture.

[0034] Soaked soybeans are heated and boiled for 10 minutes, then washed with water and shelled. Using a thermal refining soymilk machine, the shelled soybeans were intermittently refined for 7 times at 85°C and a rotational speed of 11,000 rpm, each time for 30 s, during which time insulation and heating were carried out. In order to increase the dissolution rate...

Embodiment 2

[0072] Embodiment 2, performance test

[0073] In order to study the difference in properties, the properties of soybean cheese prepared by different processes were tested. The colloid added is carrageenan CH515 (purchased from Danisco (China) Co., Ltd.), the added oil is coconut oil, and the lactic acid bacteria starter is inoculated with 0.06% (w / v) bacterial classification (Lactobacillus acidophilus NCFM) by skimmed milk. TM : Bifidobacterium HOWARUTM Bifido=1:1, purchased from Danisco (China) Co., Ltd.), obtained by fermentation at 37° C. for 18 hours; the protease used was papain.

[0074] 2.1. Sample preparation

[0075] The sample preparation process for performance testing is as follows:

[0076] The curd was fermented by lactic acid bacteria at 37°C, then the soybean cheese sample A was obtained by cutting and whey pressing, and the spreadable soybean cheese sample A was obtained through the 1.3 reprocessing process # ;

[0077] Soybean cheese sample B was obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com