Flour blending machine

A powder and material mixing technology, which is applied in the field of grain deep processing equipment, can solve problems such as susceptibility to various fungi, affect product quality, and high labor intensity, so as to avoid pollution and fungal infection, improve hygiene and environmental protection, and reduce labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

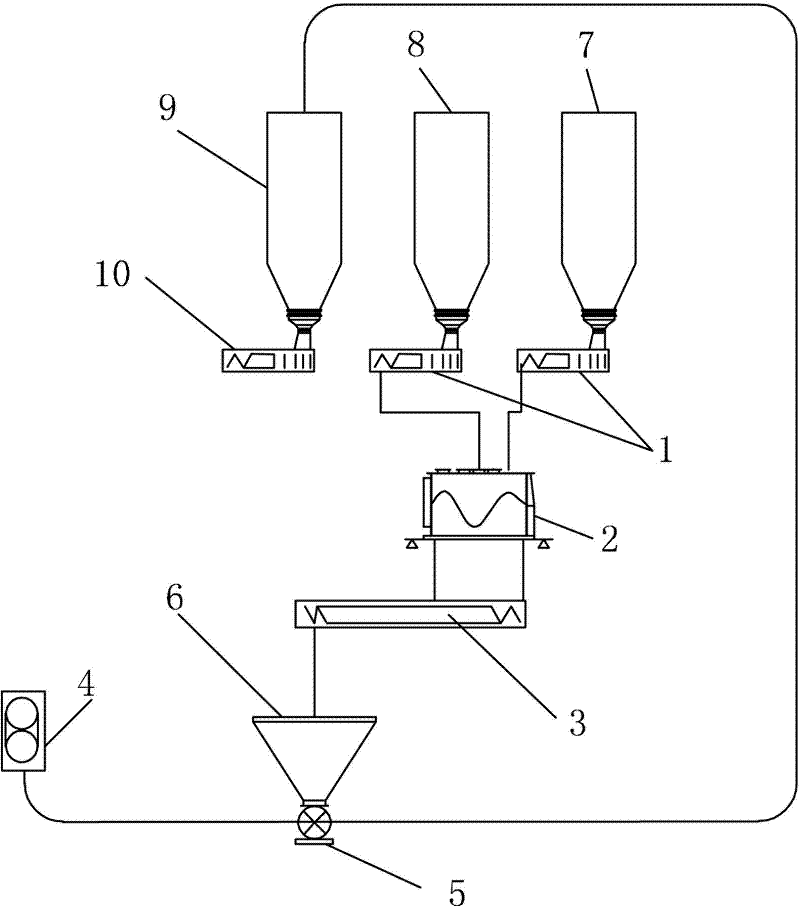

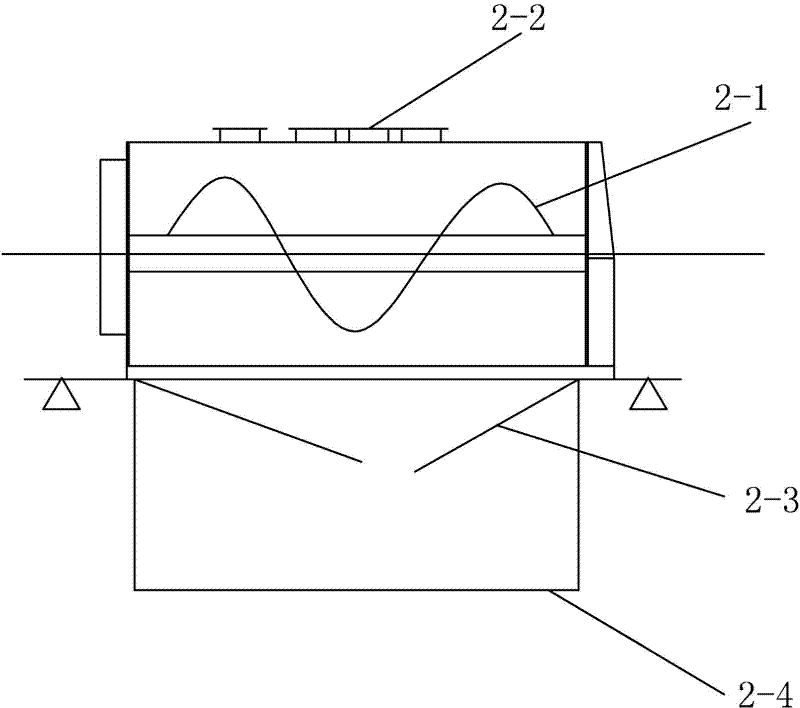

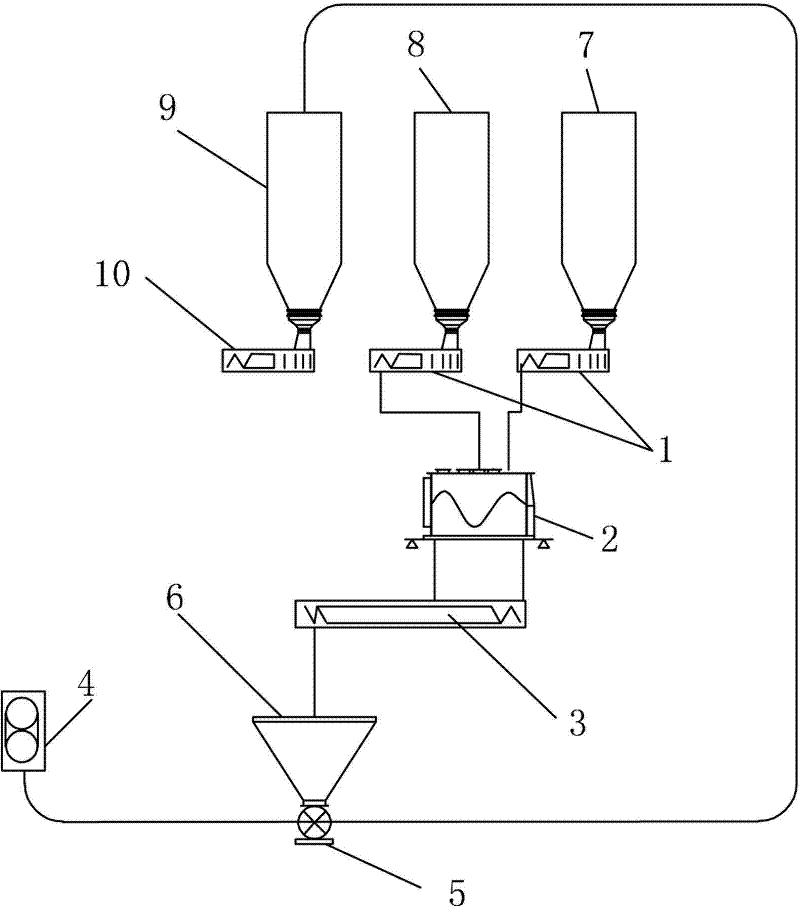

[0015] Such as figure 1 , 2 As shown; two feeding augers 1 are set above the powder dispensing machine 2 of the main machine of this equipment, and the material silo 7 before powder dispensing is arranged above the feeding dragon 1, and the lower part of the feeding auger 1 is connected to the material inlet of the powder dispensing machine 2 through a pipeline 2-2, the upper part of the powder mixing machine 2 is equipped with a material mixing screw 2-1, an automatic unloading device is added, the middle part is equipped with an automatic unloading switch door 2-3, the lower part is set with a material buffer funnel 2-4, and the bottom of the material buffer funnel 2-4 Connect the unloading Jiaolong 3, the unloading Jiaolong 3 is connected to the air locker funnel 6 through the pipe, the air locker 5 is installed at the bottom of the air locker funnel 6, and the air locker 5 is connected to the Roots blower 4 through the pipe at one end, and the finished material silo at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com