Preparation method for modified B-Beta zeolite-containing hydrocracking catalyst

A hydrocracking and beta zeolite technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of limited application scope of catalysts, inability of reactants to be removed in time, and difficult access of macromolecular hydrocarbons, etc. Achieve the effect of reducing the total synthesis time, improving the crystal synthesis and production speed, and reducing the number of miscellaneous crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Tetraethylammonium hydroxide (TEAOH) is used as template, and the raw materials are borax, sodium hydroxide and silica gel.

[0047] The molar ratio of feeding is:

[0048] SiO 2 / B 2 o 3 =30;TEAOH / B 2 o 3 =3.6; Al 2 o 3 / B 2 o 3 =0

[0049] Na 2 O / B 2 o 3 = 2; H 2 O / B 2 o 3 =200.

[0050] The first stage reaction conditions: 120°C, time: 20 hours

[0051] Second stage reaction conditions: 140°C, time: 40 hours

[0052] The third stage reaction condition: 180°C, time: 8 hours.

[0053] The synthetic sample is B-beta sample A.

Embodiment 2

[0055] Tetraethylammonium hydroxide (TEAOH) is used as a template, and the raw materials are boric acid, sodium hydroxide and water glass.

[0056] The molar ratio of feeding is:

[0057] SiO 2 / B 2 o 3 =55;TEAOH / B 2 o 3 =1.8; Al 2 o 3 / B 2 o 3 =0.5

[0058] Na 2 O / B 2 o 3 =12;H 2 O / B 2 o 3 =400.

[0059] The first stage reaction conditions: 140°C, time: 30 hours

[0060] Second stage reaction conditions: 150°C, time: 48 hours

[0061] The reaction condition of the third stage: 180°C, the time: 20 hours.

[0062] The main properties of the products obtained are listed in Table 1.

[0063] get sample B

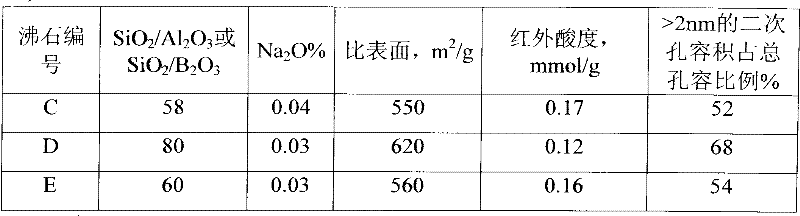

[0064] Table 1 Main physicochemical properties of B-β products

[0065] sample

Embodiment 3

[0067]The invention synthesizes modified B-beta zeolite C. Take 2000ml of A sample slurry, containing 400g of solid phase (on a dry basis), dilute the solid-liquid volume ratio to 1:10 with clean water, then add ammonium nitrate to make the concentration of ammonium nitrate in the solution 2.0M, stir, and heat up to 90 Stir at ~95°C for 2 hours at a constant temperature, then cool down to 5-60°C for filtration, and perform a second exchange of the wet filter cake under the same conditions as the first. The B-beta zeolite that has been exchanged twice with ammonium salts is washed until the pH reaches 5-6, and then placed in a drying oven and dried at 110-120° C. for 6 hours (dry basis is 88% by weight). The dried B-β zeolite is placed in a muffle furnace and rapidly raised to 250°C, kept at a constant temperature for 2 hours, then rapidly raised to 400°C, kept at a constant temperature for 4 hours, and finally raised to 540°C, kept at a constant temperature for 10 hours. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com