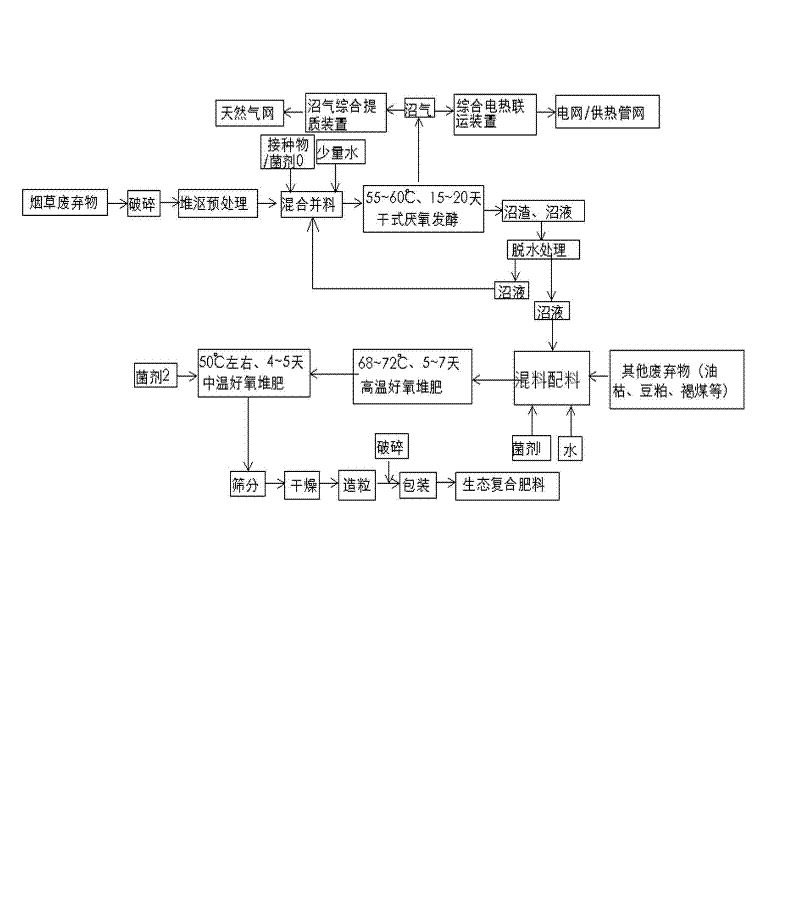

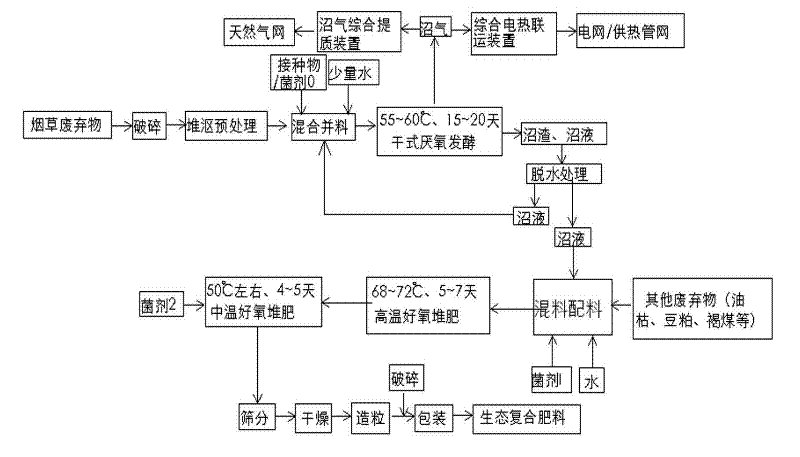

Comprehensive resource treatment process of tobacco wastes

A technology for comprehensive treatment of tobacco waste, applied in the field of environmental protection, can solve the problems of low N, P, K content, low fertilizer maturity, low organic matter content, etc., and achieves a small application range, stable fertilizer efficiency, and diversified nutrients. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] After the tobacco waste is collected, it is placed in different storage pools according to the different characteristics of the incoming materials; then the solid tobacco waste is crushed to a particle size of ≤30mm, and after 3 days of stacking, the different incoming materials are transported through the conveyor It is transported to the mixing tank and mixed with process water and anaerobic digested sludge from the sewage treatment plant to produce a mixed material with a TS concentration of 35% and a temperature of 30°C to 40°C.

[0032] The pretreated material is fed into the forced feeding device by means of a feeder or pump, and the inoculum is added to the fermentation device at the same time. The process unit is a continuous processing unit, which feeds the pretreated material into the fermentation device regularly and quantitatively, and all these processes are controlled by an automatic operating system.

[0033] The high-temperature dry anaerobic fermentatio...

Embodiment 2

[0043] After the tobacco waste is collected, it is placed in different storage tanks according to the different characteristics of the incoming materials; then the solid tobacco waste is crushed to a particle size of ≤30mm. It is transported to the mixing tank and mixed with process water, anaerobic digested sludge from sewage treatment plant and recycled biogas residue to produce a mixed material with a TS concentration of 32% and a temperature of 30°C to 40°C.

[0044] The pretreated material is fed into the forced feeding device by means of a feeder or pump, and the inoculum is added to the fermentation device at the same time. The process unit is a continuous processing unit, which feeds the pretreated material into the fermentation device regularly and quantitatively, and all these processes are controlled by an automatic operating system.

[0045] The high-temperature dry anaerobic fermentation process of tobacco waste is carried out in an anaerobic fermentation device, ...

Embodiment 3

[0049] After the tobacco waste is collected, it is placed in different storage tanks according to the different characteristics of the incoming materials; then the solid tobacco waste is crushed to a particle size of ≤30mm. It is transported to the mixing tank and mixed with process water, septic tank bottom sludge, sewer bottom sludge, and recycled biogas residue to produce a mixed material with a TS concentration of 30% and a temperature of 30°C to 40°C.

[0050] The pretreated material is fed into the forced feeding device by means of a feeder or pump, and the inoculum is added to the fermentation device at the same time. The process unit is a continuous processing unit, which feeds the pretreated material into the fermentation device regularly and quantitatively, and all these processes are controlled by an automatic operating system.

[0051] The high-temperature dry anaerobic fermentation process of tobacco waste is carried out in an anaerobic fermentation device, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com