Biological organic fertilizer as well as production method and application thereof

A bio-organic fertilizer and bio-organic fertilizer technology, applied in the direction of organic fertilizers, can solve the problems of insufficient environmental protection and energy saving, improve soil physical and chemical properties, complete nutrients, and improve soil fertilizer and water retention capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1, the preparation of biosynergist

[0054] 1) Ingredients (1000kg): Choose fresh, dry, mildew-free coarse grain bran and wheat bran as raw materials. Weigh the amount of 800kg of coarse grain bran and 200kg of wheat bran needed to produce 1 ton of synergist, spread it on the ground (or in a mixer), mix well and then flatten.

[0055] 2) Adjust the humidity and PH: Weigh 3-4kg of caustic soda and dissolve it in 45kg of clear water to fully dissolve it, stir it evenly and then spray it on the bran material, mix it well, there should be no wet lumps, use a wide range of PH1-14 The demonstration paper is tested so that the pH is 7.2, and the water content is about 40% (hand control can form a ball, loosen the hand and it will fall apart). (Note: The amount of alkali and water is an empirical figure, which should be determined according to the dryness and PH of the raw material).

[0056] 3) Bagging: Use cloth bags or woven bags, about 10kg per bag, not too muc...

Embodiment 2

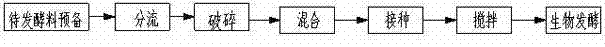

[0070] Such as figure 1 After preparing the livestock and poultry manure to be biologically fermented, blood meal, bone meal, sewage treatment plant carrier, 20% chaff, 10% distiller's grains, vinegar grains, and ammonium sulfate, they are respectively fed into the fertilizer splitter for dry and thin water splitting, splitting Biologically fermented material after water removal (livestock and poultry feces after diversion 192.4kg, blood meal 96.2kg, bone meal 96.2kg, sewage treatment plant carrier 96.2kg, chaff 192.4kg, distiller's grains 96.2kg, vinegar grains 96.2kg, ammonium sulfate 96.2kg) Enter into the crusher for crushing, after crushing, enter the mixer for mixing, after mixing, add 7kg of nitrogen-fixing bacteria, 67kg of spores, 67kg of filamentous fungi, 57kg of basidiomycetes, 87kg of yeasts, and 67kg of actinomycetes for inoculation, and enter the mixer after inoculation Stir in the middle, stir evenly, carry out biological fermentation in the biological fermenta...

Embodiment 3

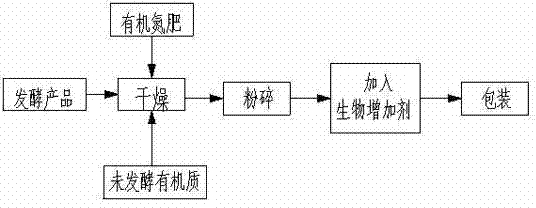

[0072] Such as figure 2 , the product after the fermentation that embodiment 2 makes, 50kg oily dryness and 100kg urea, add in drier and carry out drying, pulverize in pulverizer, after pulverizing, mix uniformly, then add the bio-enrichment product produced by the process of embodiment 1 Effect agent 10kg and mix homogeneously, pack into bag with automatic packaging machine at last. The finished packaging bags are 5kg, 10kg, 35kg, 40kg.

[0073] The bio-organic fertilizer produced in Example 2 and Example 3 can be applied in both agricultural production and forestry production.

[0074] When applied, it can be applied to various crops and should be used as a base fertilizer. Generally, 50-120 kg per mu should be applied, preferably mixed with inorganic fertilizers; fruit trees should be mixed with bio-organic fertilizers and inorganic fertilizers in autumn or early spring. Appropriately supplement the special compound fertilizer for fruit trees in summer to make the fruit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com