Method for separating propane from isopropylbenzene production facility

A technology of cumene and polycumene, which is applied in the field of propane separation in cumene equipment, can solve the problems of high benzene loss rate, high investment, cooling capacity consumption, and large heat, and achieve equipment size reduction and good technology Effect, reduce the effect of project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

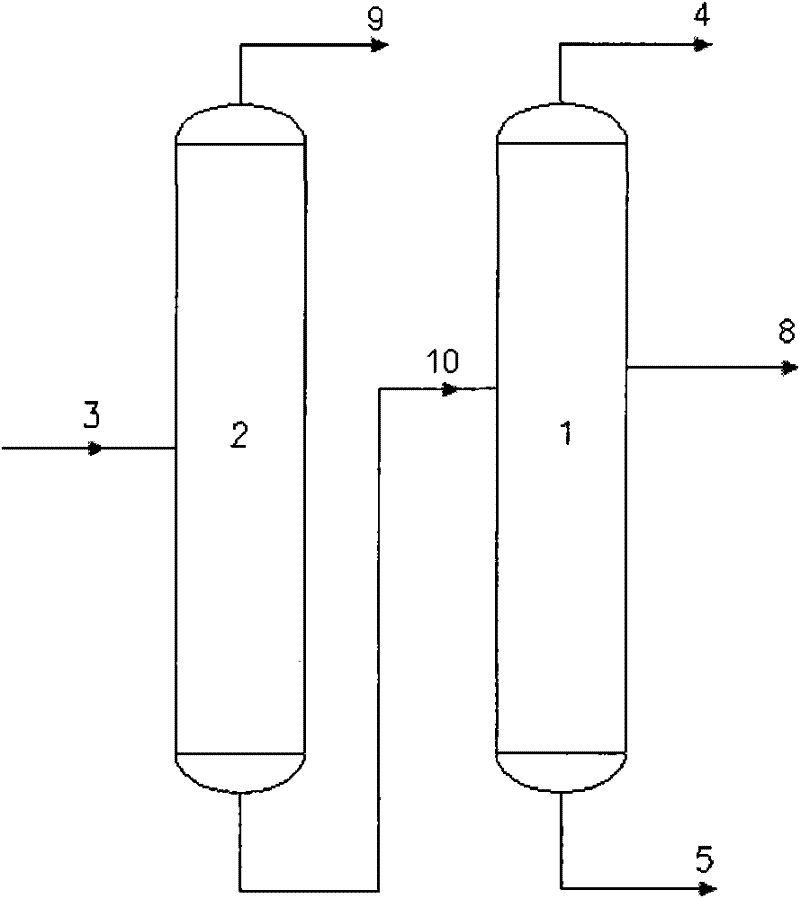

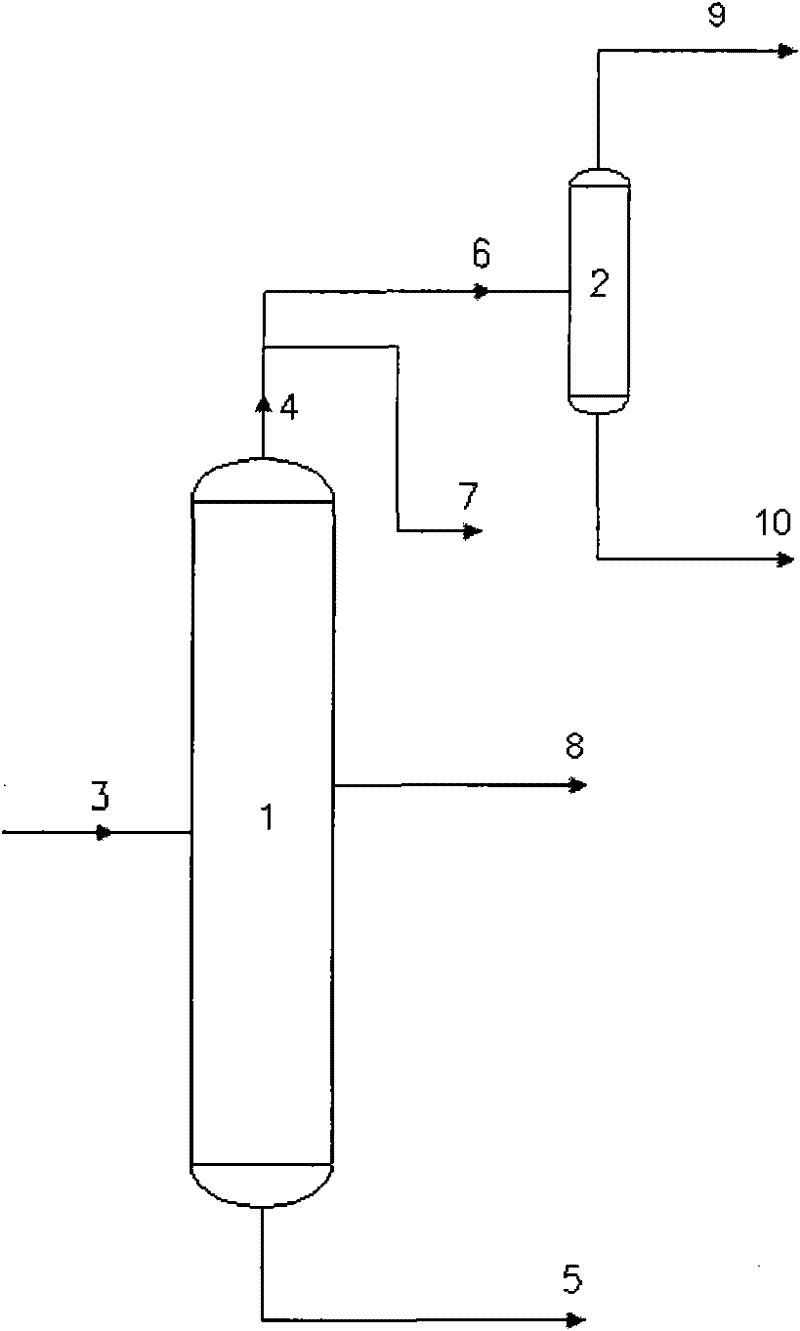

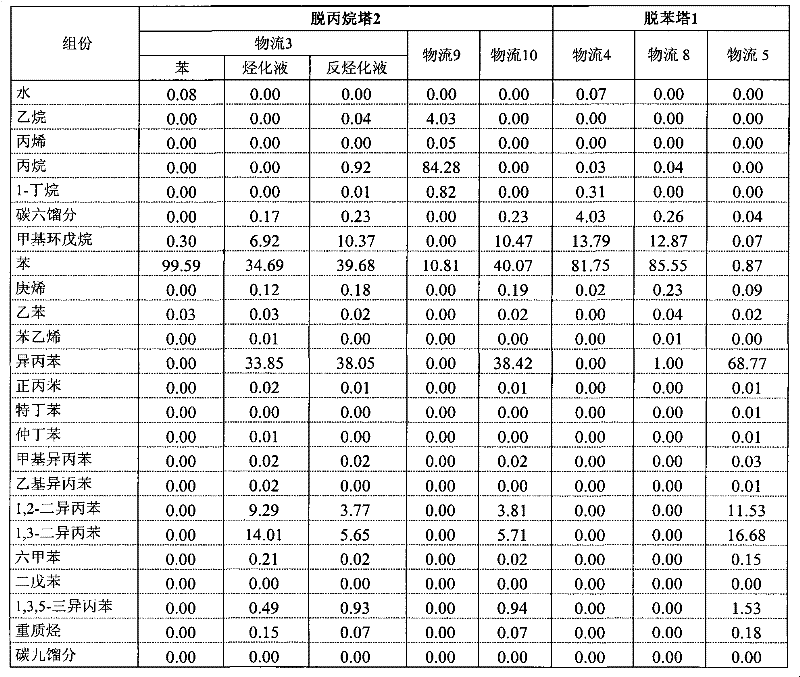

[0031] according to figure 2 As shown in the flow chart, stream 3 is composed of raw material benzene fraction, anti-alkylation liquid and alkylation liquid, which respectively enter the middle part of debenzene tower 1 and calculate the 8th tray, 20th tray and 32nd tray from top to bottom Carry out rectifying separation, tower still obtains stream 5, and stream 5 contains cumene and polycumene, but does not contain benzene and propane. The middle part of the debenzene tower 1 is counted from bottom to top at the position of the 49th tray, which is drawn and separated from the side line to obtain benzene stream 8. After the oil-water separation of the overhead stream 4, a stream 6 and water 7 containing part of benzene and all propane are obtained. The number of 1 trays of the debenzene tower is 78, the temperature of the tower bottom is 205°C, the temperature of the top of the tower is 91°C, the pressure of the top of the tower is 0.25MPa, the pressure of the bottom of the ...

Embodiment 2

[0039] By the technical process of [embodiment 1], only the operating pressure of the depropanizer is changed.

[0040] The operating conditions of each unit are shown in Table 3, and the weight percentage composition of raw materials and components of each unit is shown in Table 4.

[0041] Compared with [Comparative Example 1], the equipment size of depropanizer, condenser and reboiler are reduced. The top temperature of the depropanizer is reduced from 58°C to 40°C, and the temperature of the bottom of the tower is reduced from 225°C to 200°C, and the corresponding cooling capacity and heat consumption are reduced; on the other hand, the loss rate of benzene entrained in the discharged propane is reduced from 10.81% to 1.05%.

[0042] table 3

[0043] operating conditions

Debenzene tower 1

Depropanizer 2

Feed temperature (°C)

120

70

The number of trays at the feed (blocks)

8

21

Total number of plates (blocks) ...

Embodiment 3

[0047] According to the technical process of [Example 1], only the operating conditions of debenzene tower 1 and depropanizer 2 are changed.

[0048] The operating conditions of each unit are shown in Table 5, and the weight percentage composition of raw materials and components of each unit is shown in Table 6.

[0049] Compared with [Comparative Example 1], the equipment size of depropanizer, condenser and reboiler are reduced. The top temperature of the depropanizer is reduced from 58°C to 45°C, and the temperature of the bottom of the tower is reduced from 225°C to 210°C, and the corresponding cooling capacity and heat consumption are reduced; on the other hand, the loss rate of benzene entrained in the discharged propane is reduced from 10.81% to 0.66%.

[0050] table 5

[0051] operating conditions

Debenzene tower 1

Depropanizer 2

Feed temperature (°C)

120

70

The number of trays at the feed (blocks)

8

21

Tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com