Production method of triethylamine extracted from waste liquid by batch distillation method

A technology of triethylamine and waste liquid, which is applied in the purification/separation of amino compounds, can solve the problems of wasteful recovery of triethylamine and the inability to recycle alkali metal waste liquid, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

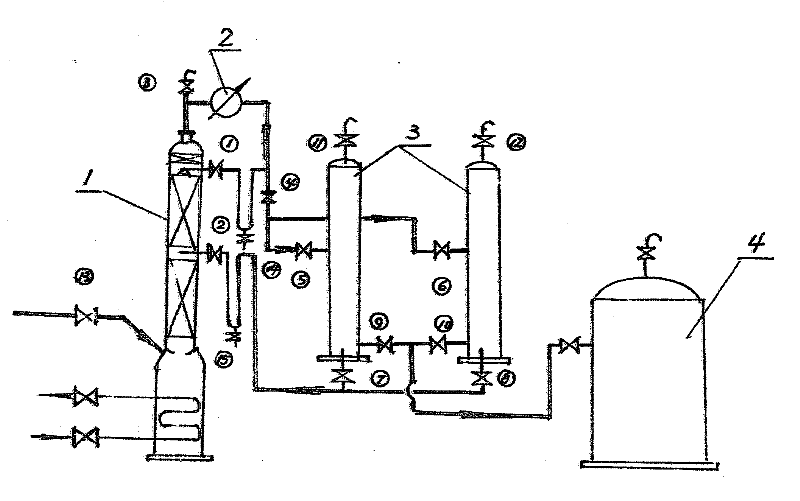

[0009] 2 implementation plan {1} flow chart

[0010] {2}Main equipment: a rectification tower b condenser 1 c condenser 2 d stratifier 1 e stratifier 2 f product storage tank 1, 2 f dosing pump

[0011] 3 operation method

[0012] A Open the liquid feeding pump and open the valve [13] When the liquid in the rectification column is added to 85% of the volume, stop the pump and close the valve [13]

[0013] B starts the heat transfer oil circulation pump, the heater sends electricity to raise the temperature, and the vent valve on the top of the tower is opened. When the temperature at the bottom of the tower reaches 54°C, close the vent valve and open the reflux valve [2] when the temperature at the bottom of the tower reaches 60---64°C, open the valve [5] valve [6] to take the liquid into the stratifier 1, when the liquid level reaches 3 / 4 o'clock close the valve [6] open the valve [7] stratifier 1 liquid static 35-50 minutes, layering. Open the valve【8】return valve【3】to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com