Preparation method for wide-temperature blue-phase liquid crystal composite material

A blue-phase liquid crystal and composite material technology, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of restricting the application of blue-phase materials and narrow temperature range, and achieve remarkable effects, good stability, and fast electric field response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

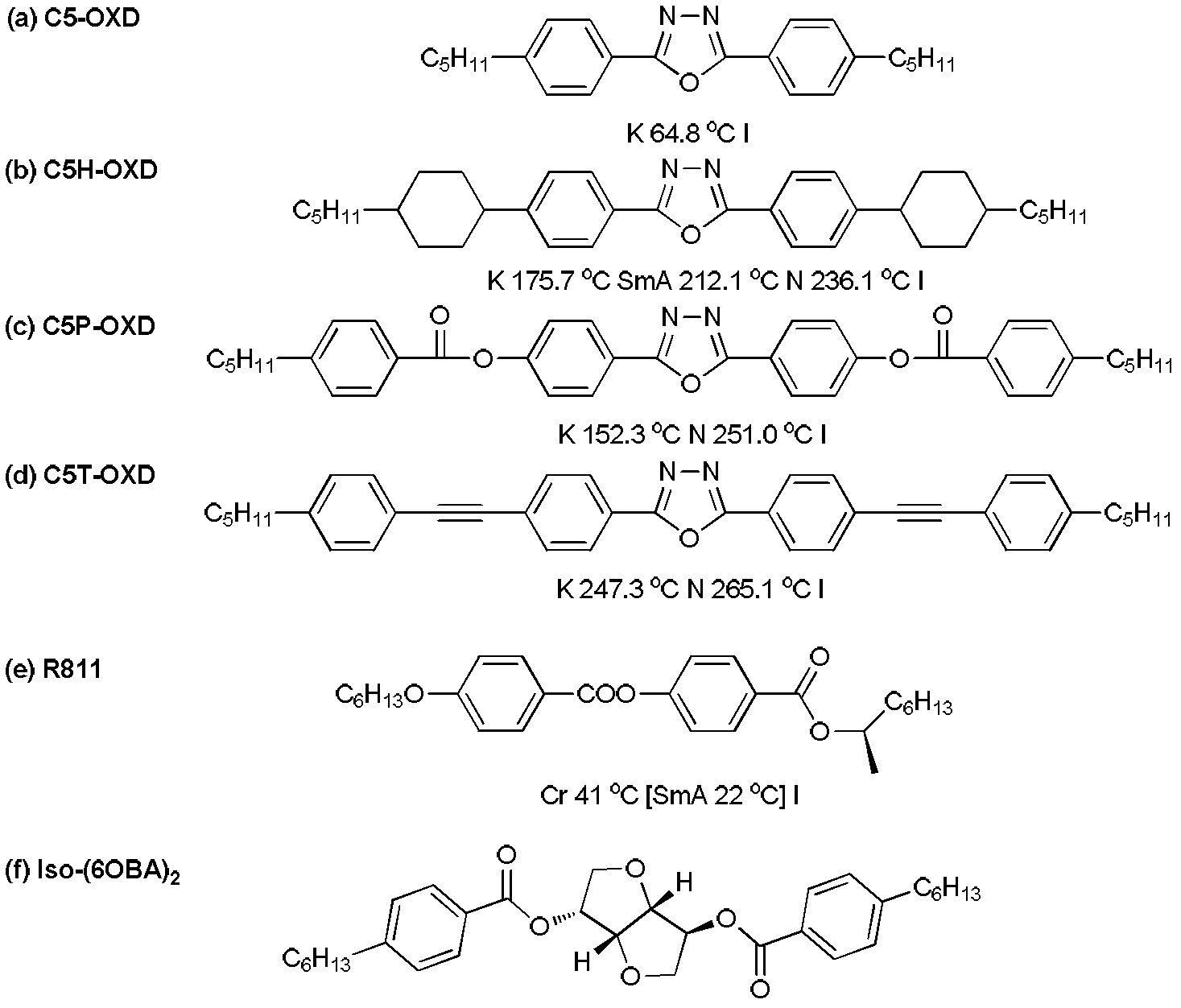

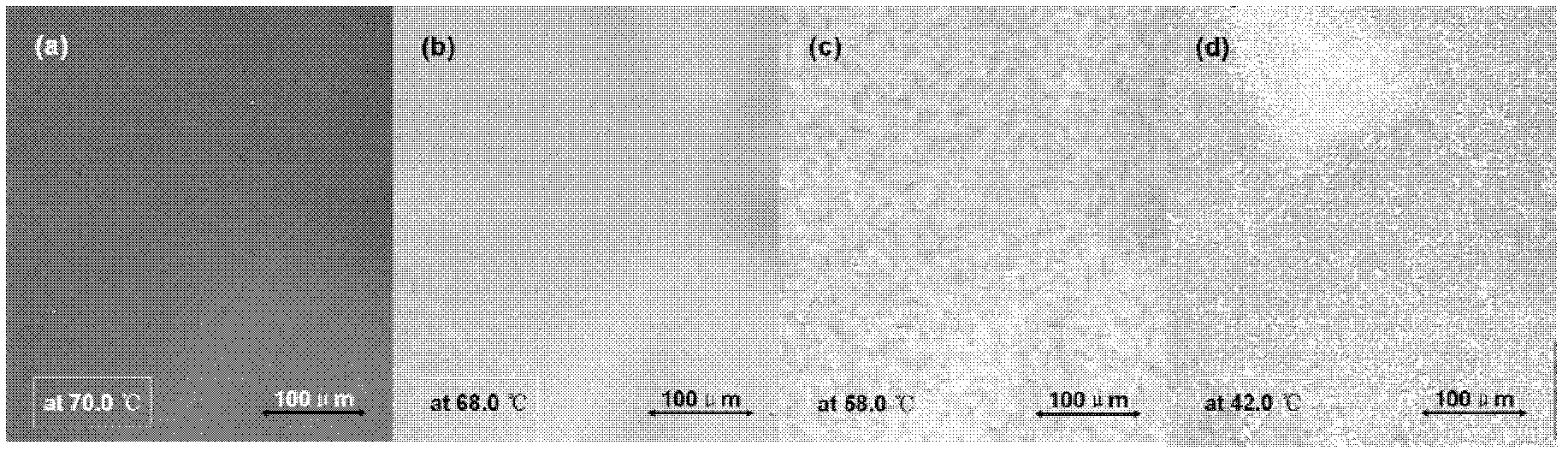

[0028] Synthesized a series of oxadiazole curved molecules, the molecular structure and phase transition temperature are as follows figure 1 shown. The composition of small molecule cholesteric liquid crystal (N*LC) is 83.0wt% mixed crystal SLC-X (Yongsheng Huatsing Liquid Crystal Co., Ltd, Δn=0.235, Δε=29.6 at 298K), 10.0wt% R811 and 7.0wt% % Iso-(6OBA)2, the oxadiazole molecules synthesized above were added to it in different proportions, and the blue phase liquid crystal texture and its phase transition temperature were observed with a polarizing microscope. The composition and phase transition of the blue phase liquid crystal composite material The temperature range is shown in Table 1, and the polarizing microscope photos when the temperature is lowered are as follows figure 2 shown.

[0029] Table 1 Composition and phase transition temperature of blue phase liquid crystal composite system

[0030]

[0031] In the table: XX-OXD: oxadiazole curved molecules; N*LC: s...

Embodiment 2

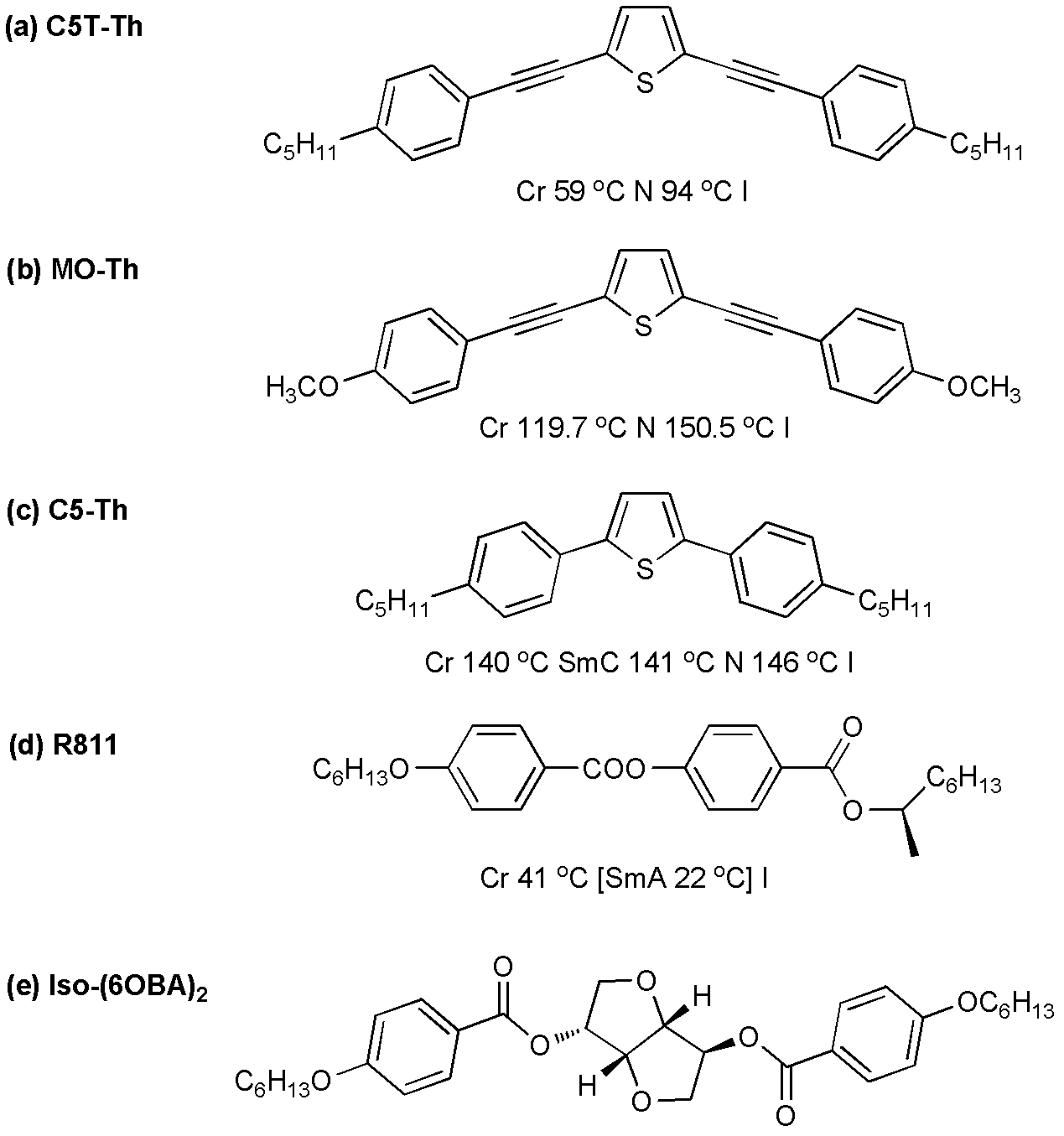

[0034] Synthesize a series of thiophene curved molecules, the molecular structure and phase transition temperature are as follows image 3 shown. The composition of small molecule cholesteric liquid crystal (N*LC) is 83.0wt% mixed crystal SLC-X (Yongsheng Huatsing Liquid Crystal Co., Ltd, Δn=0.235, Δε=29.6at 298K), 10.0wt% R811 and 7.0wt% % Iso-(6OBA) 2 , the above synthesized thiophene molecules were added in different proportions, and the blue phase liquid crystal texture and phase transition temperature were observed with a polarizing microscope. The composition and phase transition temperature range of the blue phase liquid crystal composite material are shown in Table 2.

[0035] Thiophene curved molecules have good solubility in mixed crystals, good stability, fast response speed, and remarkable effect in stabilizing the temperature range of the blue phase.

[0036] Table 2 Composition and phase transition temperature of blue phase liquid crystal composite system

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com