Focusing and leveling system capable of timely compensating wave-front distortion and compensation method thereof

A technology of focusing and leveling, wavefront distortion, applied in the field of lithography, can solve the problems affecting measurement accuracy, spot position shift, disturbance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

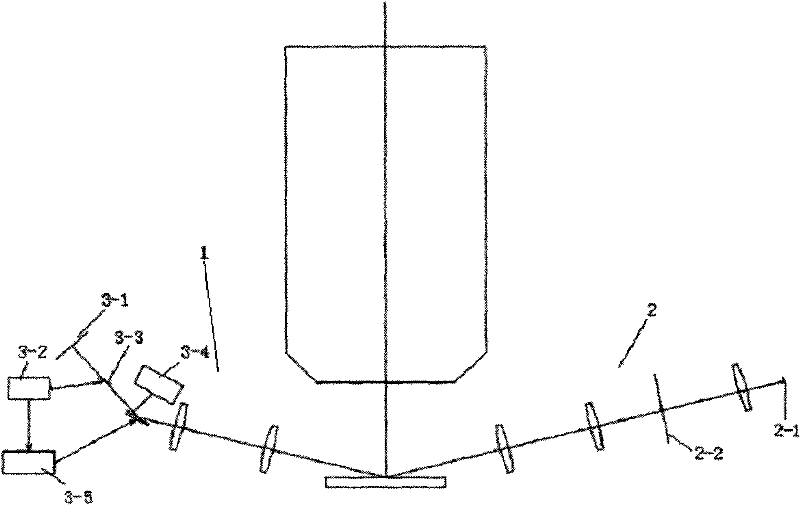

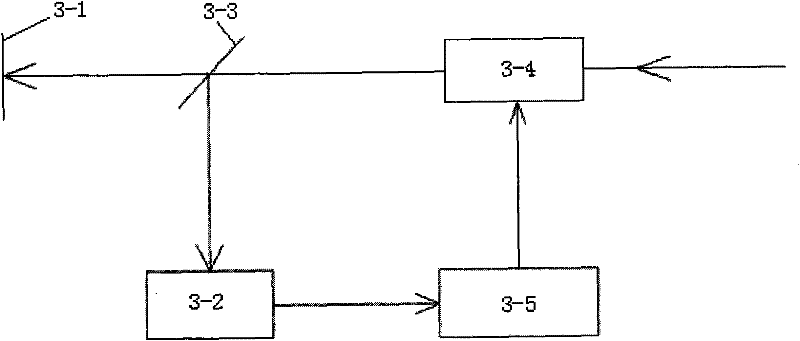

[0049] figure 2 Shown is a schematic structural view of the focusing and leveling system according to the present invention. The system inserts a closed-loop system into the existing focusing and leveling optical path. The closed-loop system consists of a wavefront sensor 3-2, a wavefront controller 3 -5 and wavefront corrector 3-4 are composed of three parts, such as image 3 shown.

[0050] Among them, the wavefront sensor 3-2 is used to detect wavefront errors in real time. The wavefront sensor 3-2 should have high precision and weak light detection capability. For example, a dynamic Hartmann-Shack wavefront sensor can be used, which consists of a microlens array 4-1 and an array detector 4-2. Figure 4 for its schematic diagram.

[0051] The wavefront controllers 3-5 are mainly used for wavefront restoration and generation of control signals.

[0052] The wavefront corrector 3-4 is mainly used to convert the control signal provided by the wavefront controller 3-5 int...

no. 2 example

[0088] The entire closed-loop system in another embodiment of the present invention consists of three parts: a wavefront sensor, a wavefront controller and a wavefront corrector, wherein the wavefront sensor and wavefront controller are similar to those of the first embodiment. Wavefront correctors 3-4 employ Figure 7 structure shown. It is made up of a plurality of small mirrors that can be independently translated or translated and tilted, and has a relatively large dynamic range of the wavefront. It can achieve high-speed and high-precision optical mirror surface shape change, translation or rotation angle under external control, thereby changing the wavefront phase of the optical system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com