Anion-exchange membrane and preparation and application thereof

An anion-exchange membrane and positive-ion technology, which is applied in the field of anion-exchange membranes for alkaline fuel cells and liquid flow energy storage batteries and their preparation, can solve problems such as high cost, inability to ensure uniform brushing, and complex raw materials, and achieve improved The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 3 g of polysulfone was dissolved in 120 ml of chloroform (dried to remove water in advance), and 240 microliters of SnCl were added to the resulting solution under nitrogen protection, and then 5 ml of chloromethyl methyl ether were slowly added; stirred at 50° C. for 12 hours, the The resulting solution was precipitated in 400 ml of rapidly stirred methanol, stirred overnight, then filtered, and washed 3-5 times with methanol, and finally the white precipitate was vacuum-dried at 60°C for 12 hours; Chloromethyl polysulfone.

[0039] Weigh 0.5 g of the product obtained above, use DMAc as a solvent to prepare a solution with a concentration of 10% (w / v), add 120 microliters of 1-methylimidazole to it, stir at 25°C for 12 hours, and then cast on a glass plate Film formation, drying at 60°C for 24 hours, then vacuum drying at 100°C for 12 hours; finally immersion in 0.5M NaOH aqueous solution at 25°C for 24 hours.

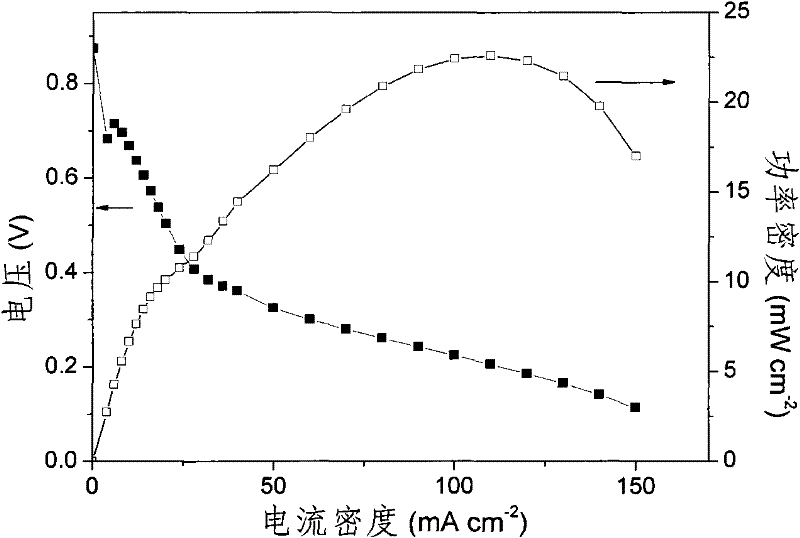

[0040] The IEC of the obtained anionic membrane was 1.27...

Embodiment 2

[0042] 3 g of polysulfone was dissolved in 120 ml of chloroform (dried to remove water in advance), and 240 microliters of SnCl4 was added to the resulting solution under nitrogen protection, and then 5 ml of chloromethyl methyl ether was slowly added; stirred at 50 ° C for 21 hours, the The resulting solution was precipitated in 400 ml of rapidly stirred methanol, stirred overnight, then filtered, and rinsed with methanol 3-5 times, and finally the white precipitate was vacuum-dried at 60°C for 12 hours; the product was chloromethyl degree (DCM) 1.40 Chloromethyl polysulfone.

[0043] Weigh 0.5 g of the product obtained above, use DMAc as a solvent to prepare a solution with a concentration of 10% (w / v), add 120 microliters of 1-methylimidazole to it, stir at 25°C for 12 hours, and then cast on a glass plate Film formation, drying at 60°C for 24 hours, and vacuum drying at 100°C for 12 hours to obtain a Cl-type anion membrane.

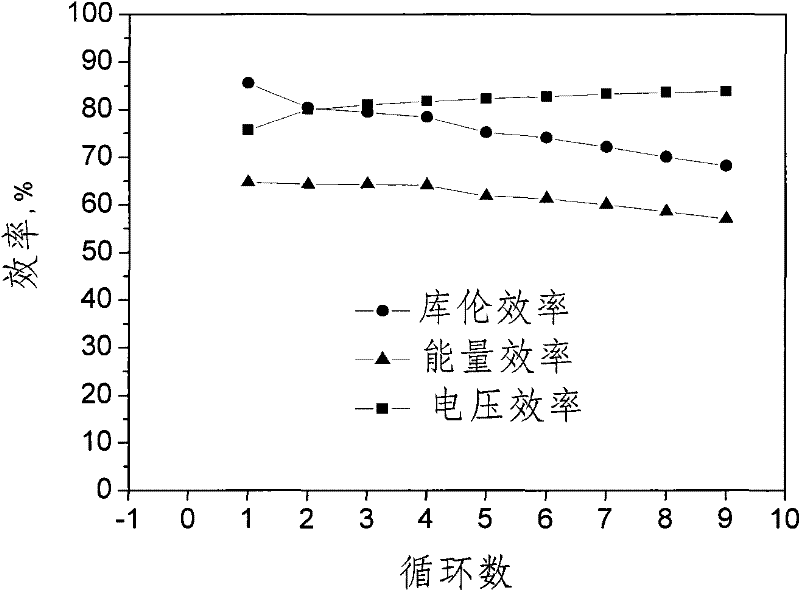

[0044] The ionic conductivity of the obtained ...

Embodiment 3

[0046] 2 g of polysulfone was dissolved in 80 ml of chloroform (dried to remove water in advance), and 120 microliters of SnCl4 was added to the resulting solution under nitrogen protection, and then 3.4 ml of chloromethyl methyl ether was slowly added; stirred at 50 ° C for 12 hours, the The resulting solution was precipitated in 300 ml of rapidly stirred methanol, stirred overnight, then filtered, and rinsed with methanol 3-5 times, and finally the white precipitate was vacuum-dried at 60°C for 12 hours; the product was chloromethyl degree (DCM) 1.14 Chloromethyl polysulfone.

[0047] Weigh 0.25 g of the product obtained above, use DMAc as a solvent to prepare a solution with a concentration of 5% (w / v), add 60 microliters of 1-methylimidazole to it, stir at 25°C for 12 hours, and then cast on a glass plate Film formation, drying at 60°C for 30 hours, and vacuum drying at 100°C for 12 hours to obtain a Cl-type anion membrane.

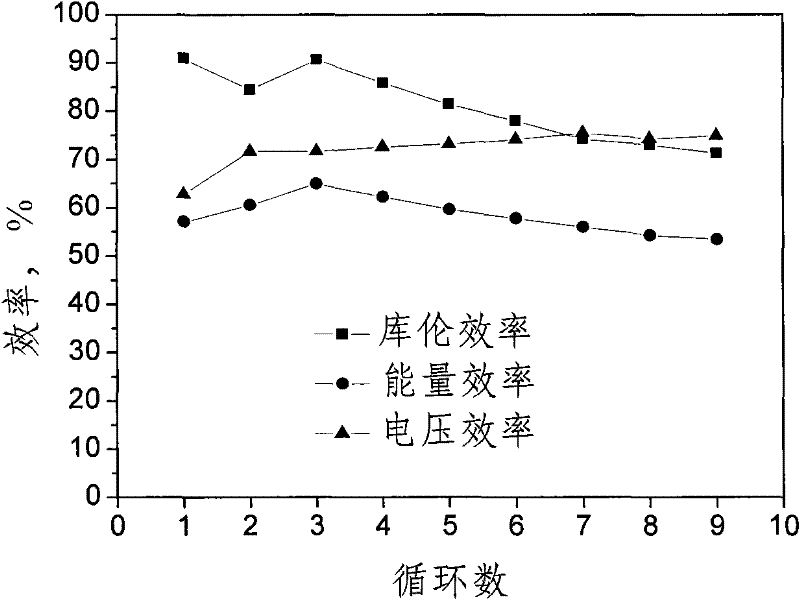

[0048] The resulting anion membrane assembled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| voltage efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com