Method for transforming aqueous solution containing copper chloride into copper powder and polyaluminum chloride (PAC)

A technology of polyaluminum chloride and copper chloride, applied in aluminum chloride, aluminum halide and other directions, can solve the problems of long processing time, high impurities in copper powder and high copper content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples. It should be understood that these examples are only for the purpose of illustration, and in no way limit the protection scope of the present invention.

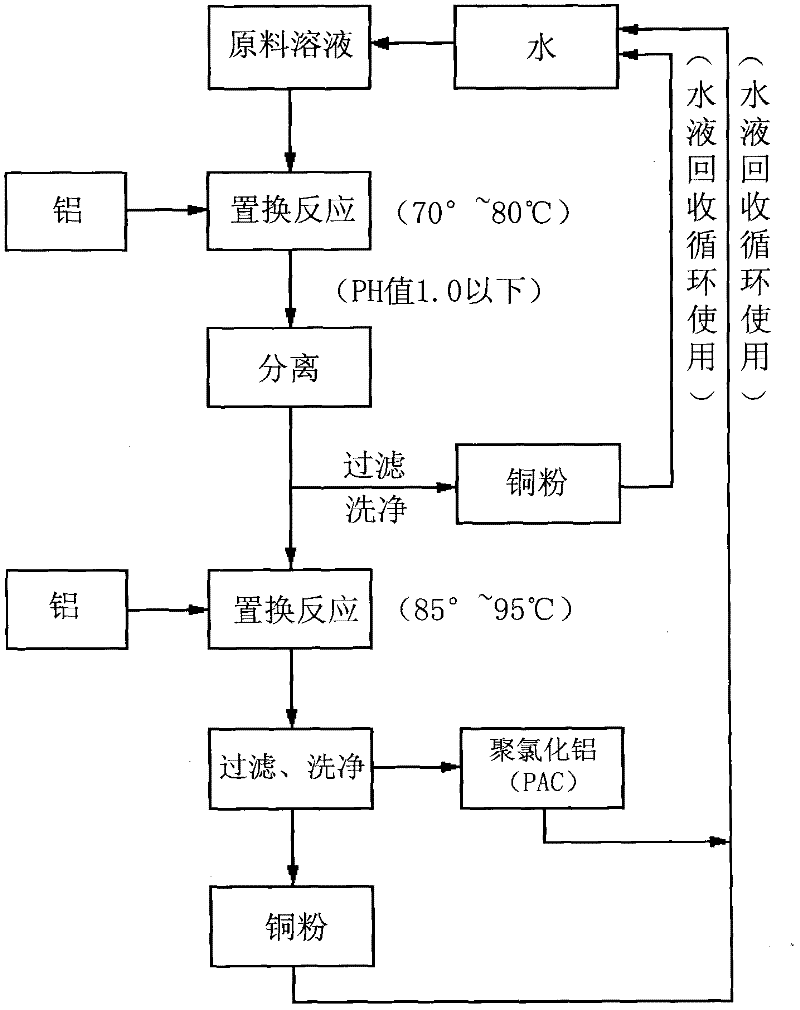

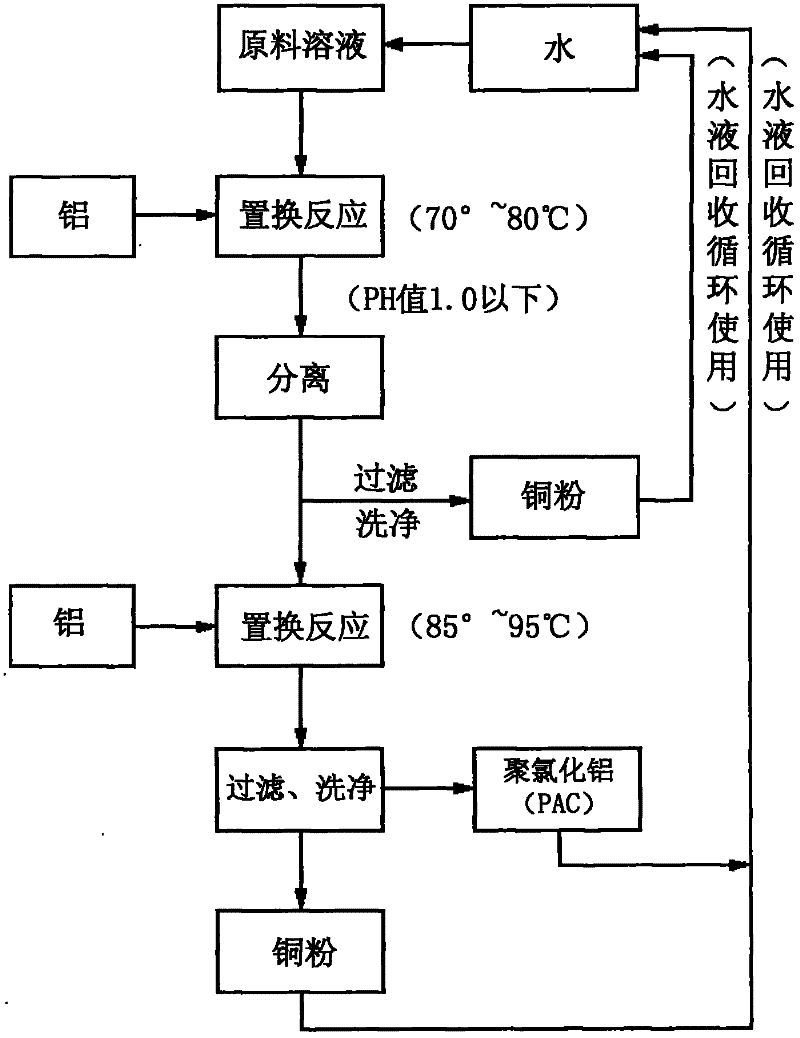

[0025] figure 1 It is an embodiment of the method of the present invention. The inventive method is that raw material solution (the waste liquid containing copper chloride aqueous solution) is diluted with water to [Cu 2+ ] Concentration is 40~60g / l (step 1), under the state of temperature being 70~80 ℃, carries out replacement reaction (step 2) with high-purity aluminum sheet, when reaction solution pH value is below 1.0, make the Copper powder separation (step 3), the drum washing method can be used for the separation, in order to obtain excellent quality copper powder (step 4), the water used for drum washing and separation of copper powder is recovered to the raw material diluted with water solution; after the copper powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com