Treating equipment for waste containing sludge

A technology for treating equipment and waste, which is applied in water/sludge/sewage treatment, ceramic wastewater treatment, solid waste removal, etc., and can solve the problem of increased sewage sludge treatment volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

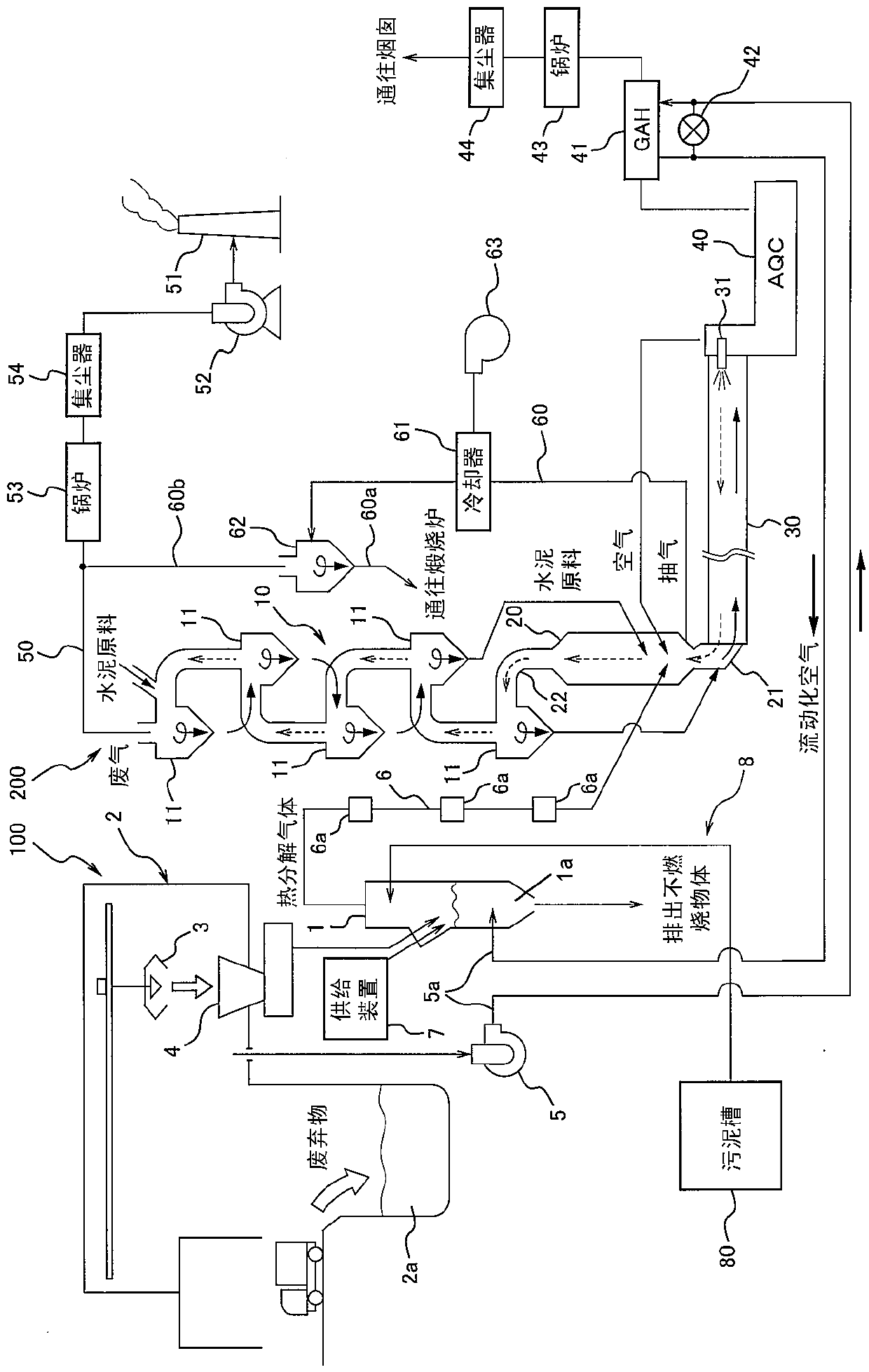

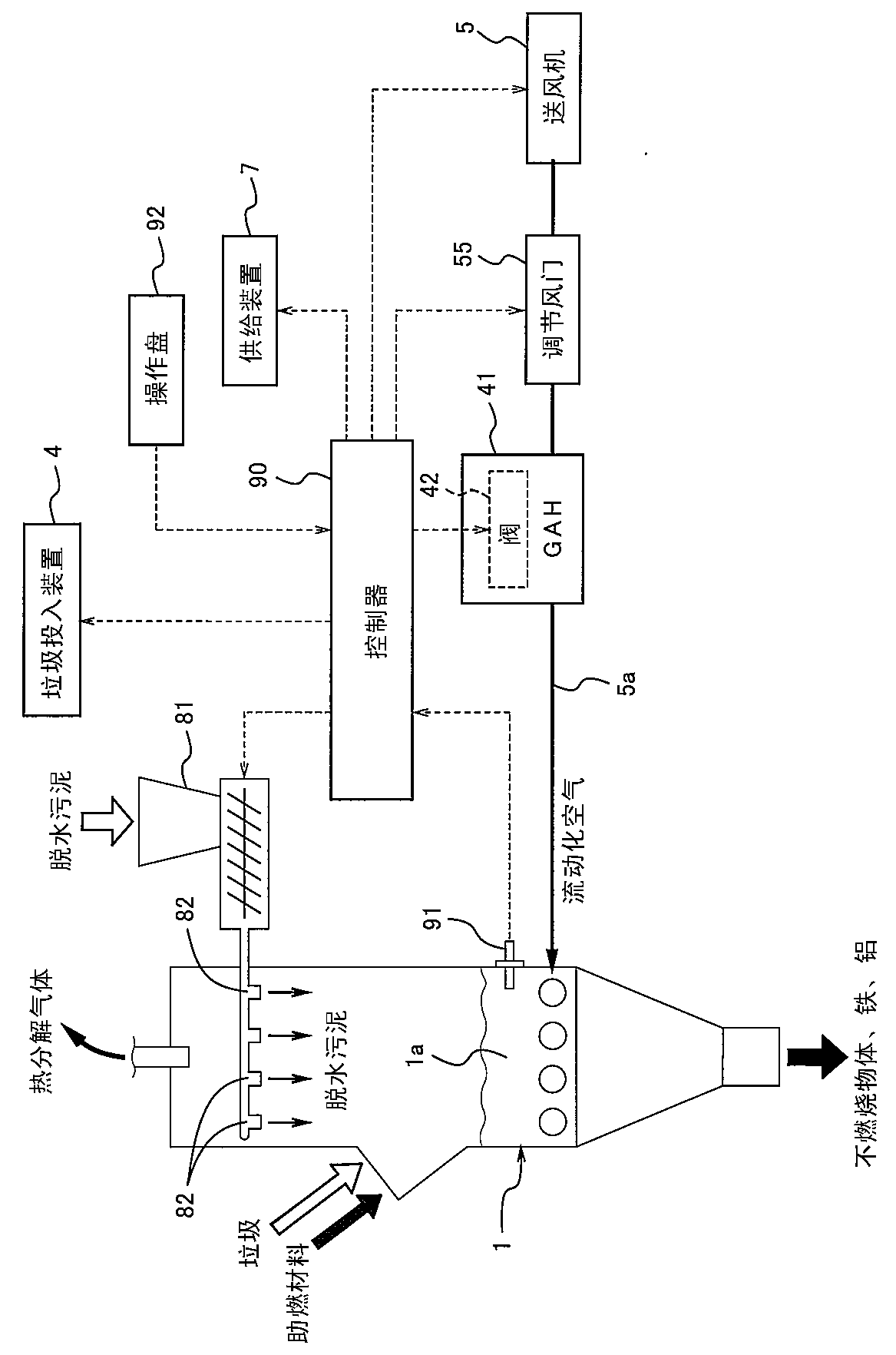

[0059] Preferred embodiments of the present invention will be described below with reference to the drawings. figure 1 It is an overall system diagram of the waste disposal facility 100 of the first embodiment and the cement manufacturing facility 200 installed adjacent thereto. figure 1 The waste treatment facility 100 shown on the left side of the center thermally decomposes waste in the gasification furnace 1 and uses the generated gas (pyrolysis gas) for mixed combustion in the cement firing process. The amount of the pyrolysis gas is, for example, 20,000 to 30,000 Nm 3 / h, and the exhaust gas volume of the cement manufacturing equipment shown in the figure 200 (for example, 300,000 Nm 3 / h) is much less, so the waste treatment plant 100 can be built next to an existing cement plant with little or no modification to the existing cement plant.

[0060] Waste Treatment Equipment

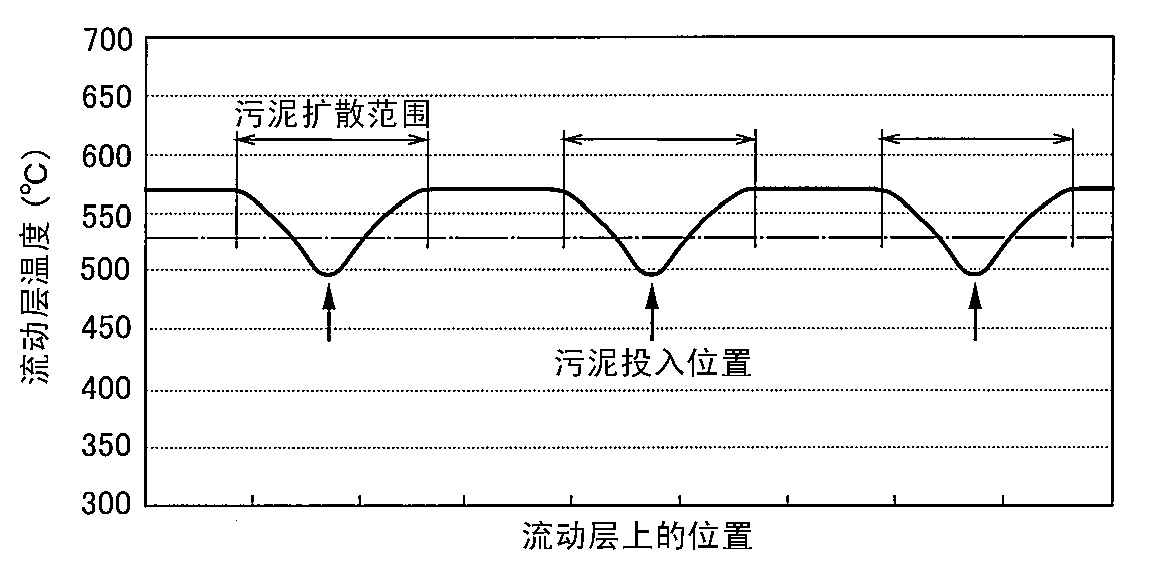

[0061] In the waste treatment facility 100, for example, waste from households, waste plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com