Aqueous inkjet ink for digital printing

A water-based inkjet, digital printing technology, applied in inks, household appliances, applications, etc., can solve the problems of fast drying, poor color fastness and printing stability, poor color fastness and color reproduction, etc. To achieve the effect of strong quality stability and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

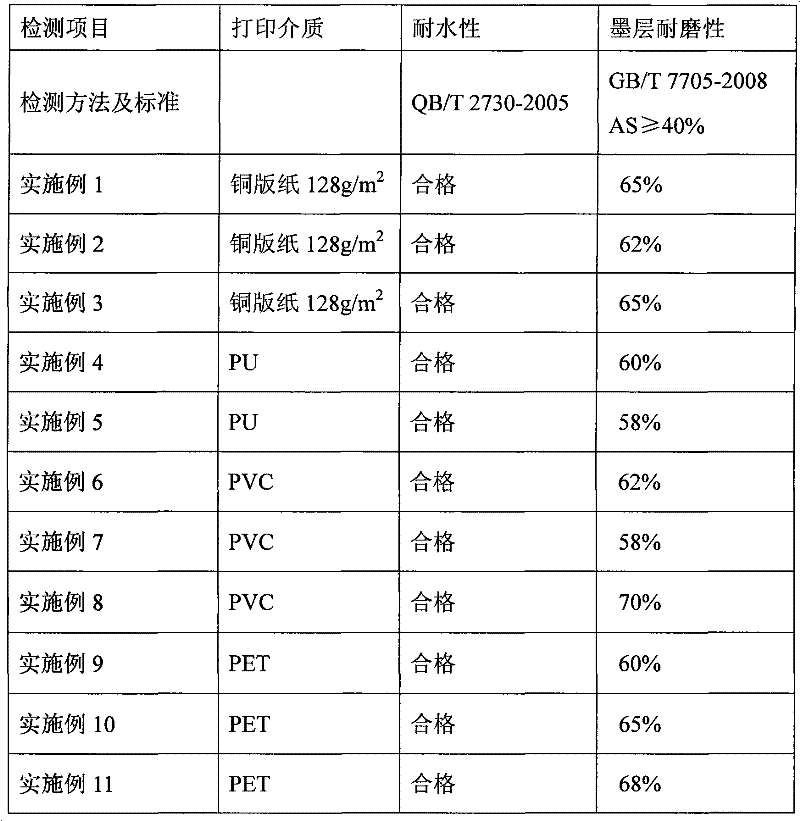

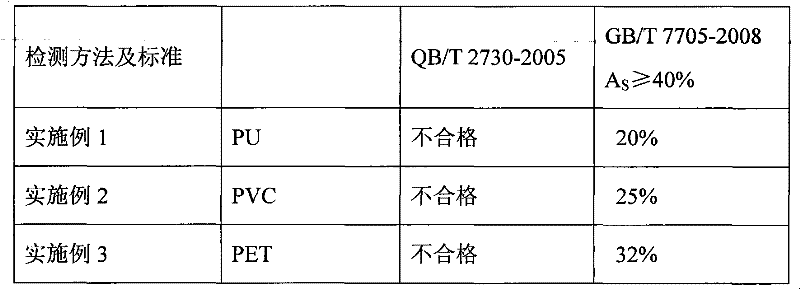

Examples

Embodiment 1

[0026] According to the weight percentage, it includes the following components: C.I. Pigment Black 7 (particle size 50-150nm) 8%, diethylene glycol ether 15%, polyurethane 20%, polyether modified polydimethylsiloxane BYK-348 2% , 1% of 5-chloro-2-methyl-4-isothiazolin-3-one, 0.1% of sodium hydroxide, and the rest is deionized water.

[0027] After the above components are stirred and mixed evenly, they are filtered through a filter membrane with a pore size of 0.45 microns to obtain the digital printing water-based inkjet ink of the present invention.

Embodiment 2

[0029] According to the weight percentage, it includes the following components: C.I. Pigment Blue 15:3 (particle size 70~180nm) 7%, diethylene glycol methyl ether 20%, polyurethane 15%, polyether modified polydimethylsiloxane BYK- 348 1.5%, 5-chloro-2-methyl-4-isothiazolin-3-one 0.5%, ammonium hydroxide 2%, the rest is deionized water.

[0030] After the above components are stirred and mixed evenly, they are filtered through a filter membrane with a pore size of 0.45 microns to obtain the digital printing water-based inkjet ink of the present invention.

Embodiment 3

[0032] The following components are included in terms of weight percentage: C.I. Pigment Violet 19 (particle size 90-190nm) 6%, diethylene glycol ether 10%, polyurethane 10%, polyether modified polydimethylsiloxane BYK-345 1.0% , 0.5% of 5-chloro-2-methyl-4-isothiazolin-3-one, 1.5% of ammonium hydroxide, and the rest is deionized water.

[0033] After the above components are stirred and mixed evenly, they are filtered through a filter membrane with a pore size of 0.45 microns to obtain the digital printing water-based inkjet ink of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com