Preparation method of graphene

A technology of graphene and expanded graphite, which is applied in the field of organic semiconductor materials and can solve the problems of low yield and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

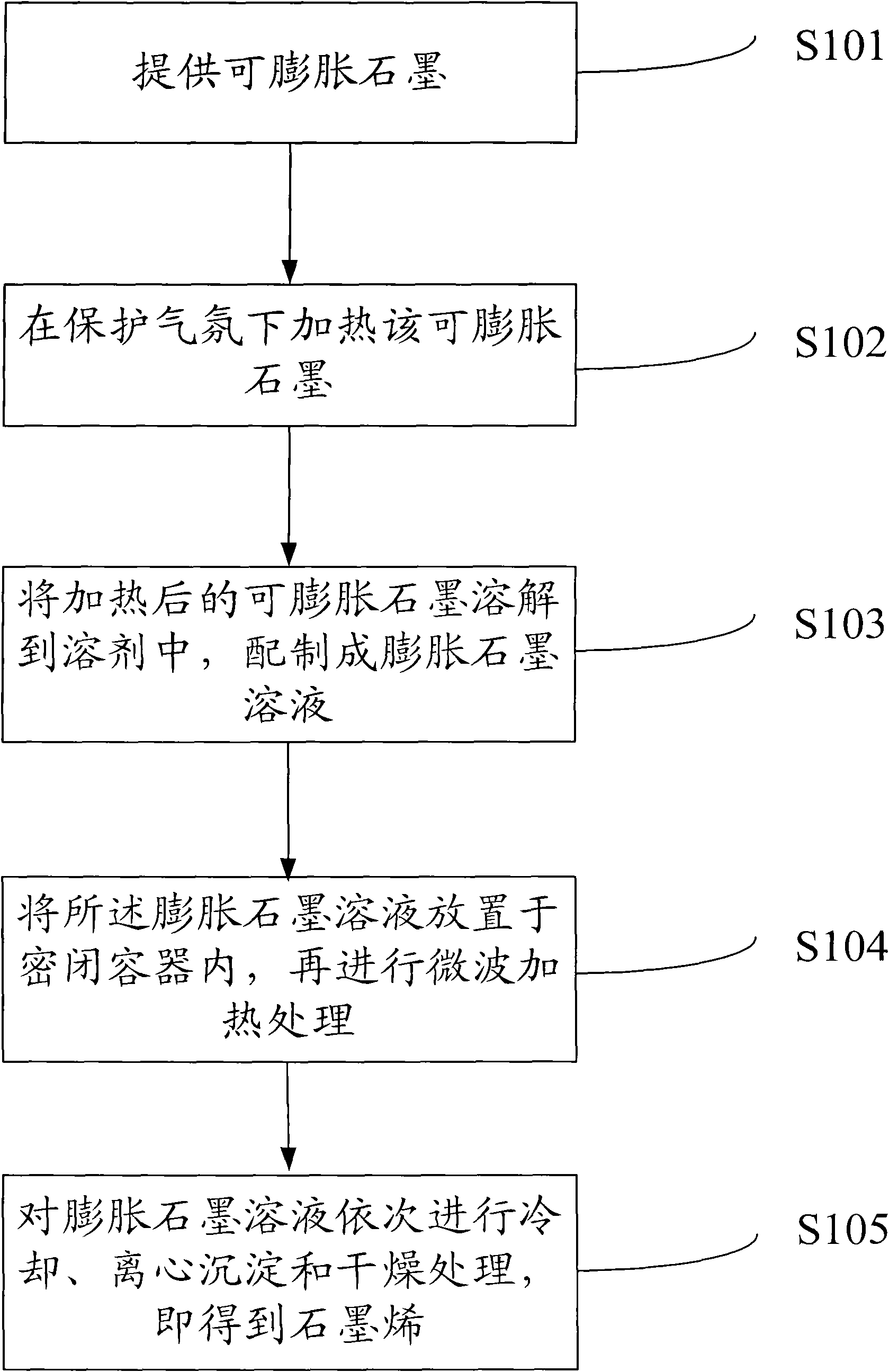

[0029] A kind of preparation method of high-purity graphene, its technological process is as follows:

[0030] (1) Provide expandable graphite with an average diameter of 300 μm and a purity of 99%;

[0031] (2) The expandable graphite is fed into the mixed gas (5%H 2 and 95% Ar), heated to 800°C for 120s to form expanded graphite;

[0032] (3) The expanded graphite (1mg) in (2) is joined in the DMF solution of 20ml, is mixed with expanded graphite solution after ultrasonic 30min, and mixed solution is put into quartz reactor;

[0033] (4) Put the reactor in (3) into a microwave oven, adjust the power of the microwave to 600W, and heat at a temperature of 180° C. for 5 minutes.

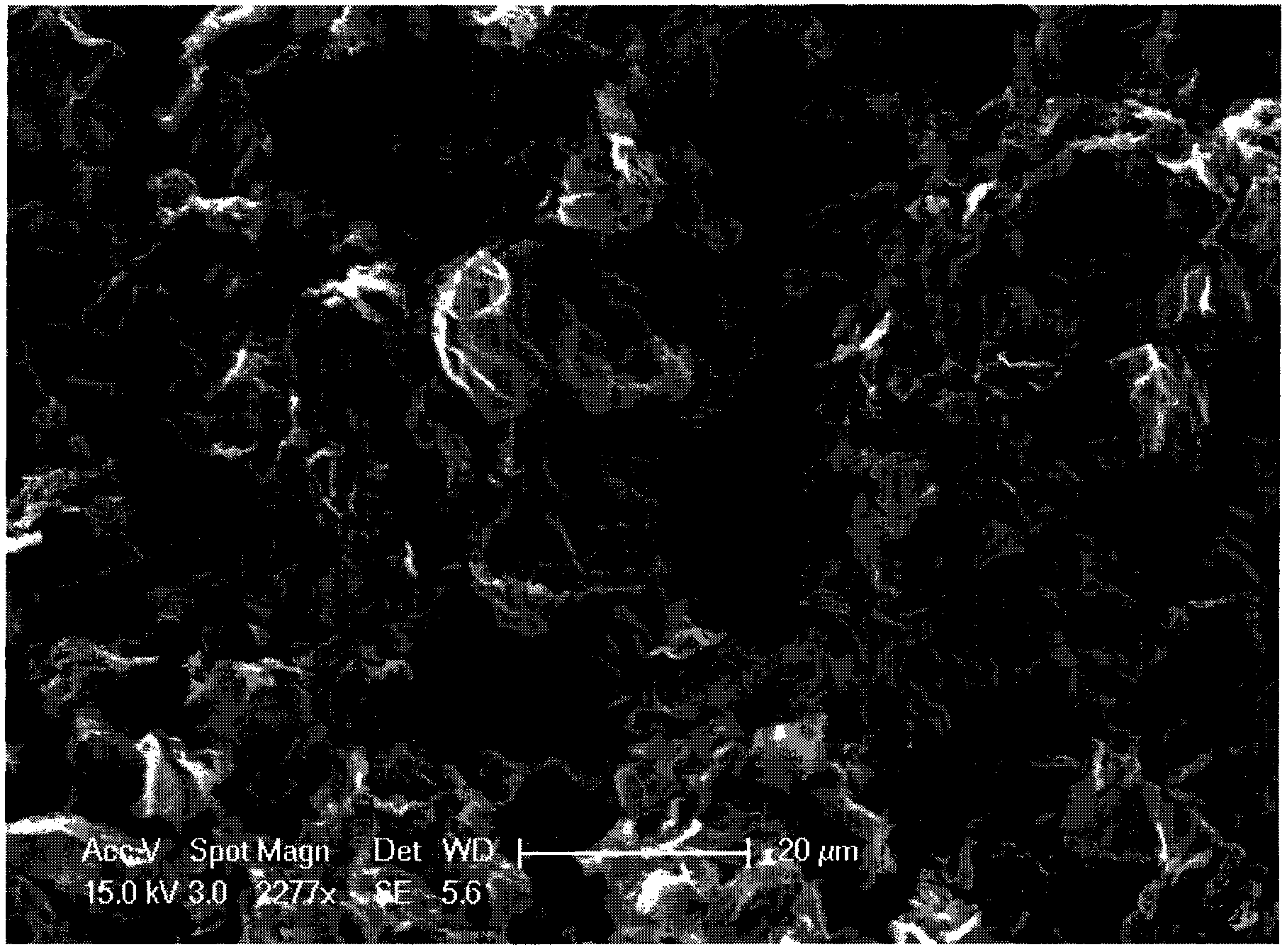

[0034] (5) Cool the reactor to room temperature, and centrifuge at 600rpm for 120 minutes, filter out the black graphene precipitate, wash repeatedly with acetone and ethanol, and dry in a vacuum oven at 80°C to finally obtain high-purity graphene The final yield of graphene can reach 10-15%.

Embodiment 2

[0036] A kind of preparation method of high-purity graphene, its technological process is as follows:

[0037] (1) Provide expandable graphite with an average diameter of 500 μm and a purity of 99%;

[0038] (2) The expandable graphite is fed into the mixed gas (2%H 2 and 98% Ar), heated to 1200°C for 60s to form expanded graphite;

[0039] (3) The expanded graphite (1mg) in (2) is added to the pentafluorobenzonitrile (C 6 f 5 CN) solution, after ultrasonic 30min, be mixed with expanded graphite solution, the mixed solution is put into quartz reactor;

[0040] (4) Put the reaction kettle in (3) into a microwave oven, adjust the power of the microwave to 800W, and heat at a temperature of 300° C. for 15 minutes.

[0041] (5) Cool the reactor to room temperature, and ultrasonicate at a rate of 900rpm for 90 minutes, filter out the black graphene precipitate, wash repeatedly with acetone and ethanol, and dry in a vacuum oven at 100°C to finally obtain high-purity graphene Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com